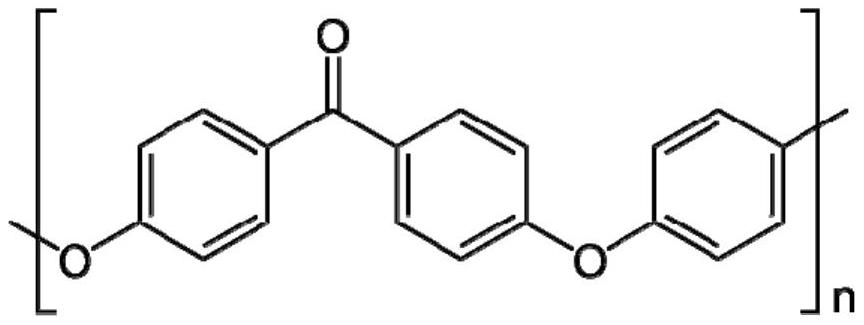

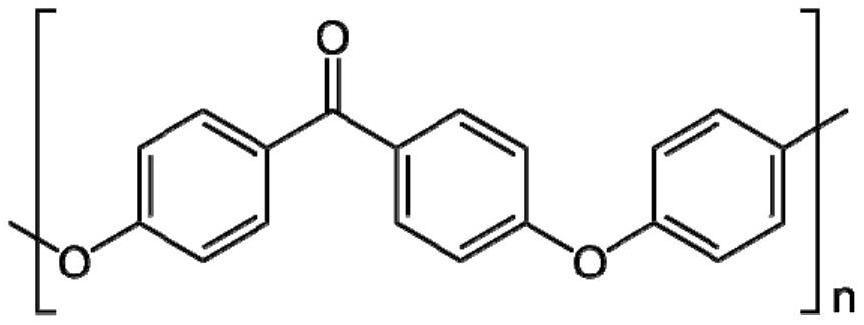

Polyaryletherketone fiber, non-woven fabric and preparation method and application thereof

A technology of polyaryletherketone and non-woven fabric, which is applied in the field of polyaryletherketone fiber and its preparation, can solve the problems of thick fiber, high cost, and different processing methods, and achieve fine fiber, high strength and good filtering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the polyaryletherketone fiber of the present invention comprises the following steps: (1) the step of preparing spinning dope; (2) the step of preparing fiber.

[0028] Steps for preparing spinning dope

[0029] The polyaryletherketone is dissolved in a solvent to form a spinning dope. The dissolution temperature may be 250-500°C; preferably 300-400°C; more preferably 330-370°C. The dissolution pressure may be 1-50 MPa; preferably 5-40 MPa; more preferably 7-20 MPa.

[0030] The polyaryletherketone and the solvent can be mixed under stirring to form a spinning dope. The stirring speed may be 80-200 rpm; preferably 100-150 rpm; more preferably 110-130 rpm. The mixing time can be 1~20h; preferably 2~10h; more preferably 3~5h. Using the above conditions, the polyaryletherketone can be fully dissolved in the solvent to form a spinning dope with good uniformity, thereby increasing the strength of the fiber.

[0031] The content of polyarylethe...

Embodiment 1~3

[0056] Put polyether ether ketone and carbon tetrachloride in a high-pressure reactor, and mix them for 3 hours at a temperature of 350 °C, a pressure of 10 MPa, and a stirring speed of 120 rpm to obtain a spinning stock solution with a polyether ether ketone concentration of 3 wt%. .

[0057] The spinning stock solution is sprayed out from the spinneret of the flash spinning equipment, and the carbon tetrachloride in the spinning stock solution evaporates instantly to obtain polyether ether ketone fibers.

[0058] The polyetheretherketone fibers are formed into a fiber web on the accumulating belt, and the fiber web is hot-rolled by rollers to form a polyaryletherketone nonwoven fabric.

[0059] The specific parameters are shown in Table 1. The properties of fibers and non-woven fabrics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com