Multifunctional power machinery test platform and test method thereof

A technology of power machinery and test platform, which is applied in the field of power machinery, can solve the problems of aggravating workshop test production tasks, high investment costs of test platforms, and large floor space, so as to achieve rich platform functions, shorten project cycles, and save space and land occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

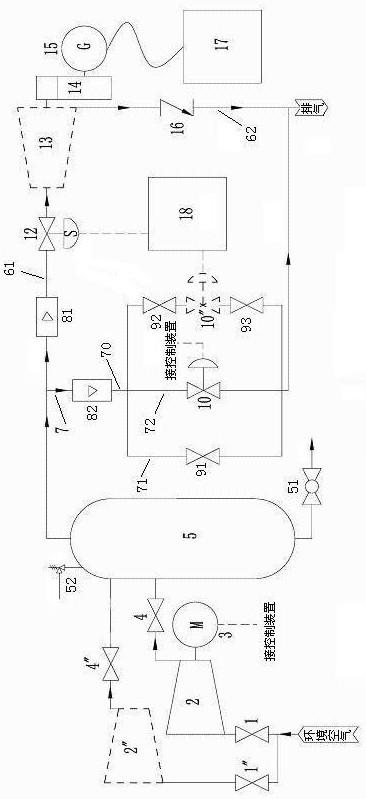

[0034] see figure 1 . According to an embodiment of the present invention, the multifunctional power machinery test platform includes a first suction valve 1, a second suction valve 1", a compressor 2, a compressor test stand 2", a motor 3, and a first exhaust valve 4 , second exhaust valve 4", gas buffer tank 5, first flow meter 81, second flow meter 82, first stop valve 91, second stop valve 92, third stop valve 93, regulating valve 10, regulating valve And quick-closing valve test bench 10", quick-closing valve 12, expander test bench 13, expander test load assembly, expander intake pipeline 61, expander exhaust pipeline 62, bypass pipeline 7 and control device 18.

[0035] The first suction valve 1 links to each other with the air inlet of compressor 2, and the air outlet of compressor 2 connects the first air inlet of gas buffer tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com