Wire cord fabric detection and calibration device and detection and calibration method

A technology for detecting and calibrating devices and steel cords, applied in the direction of material magnetic variables, etc., can solve the problems of different initial excitation magnetic field signals of array magnetic field units, the original output of magneto-sensitive elements deviates from the initial installed value, and the output of array magneto-sensitive elements is not the same. , to achieve a wide range of applications, increase the distance, and meet the effect of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

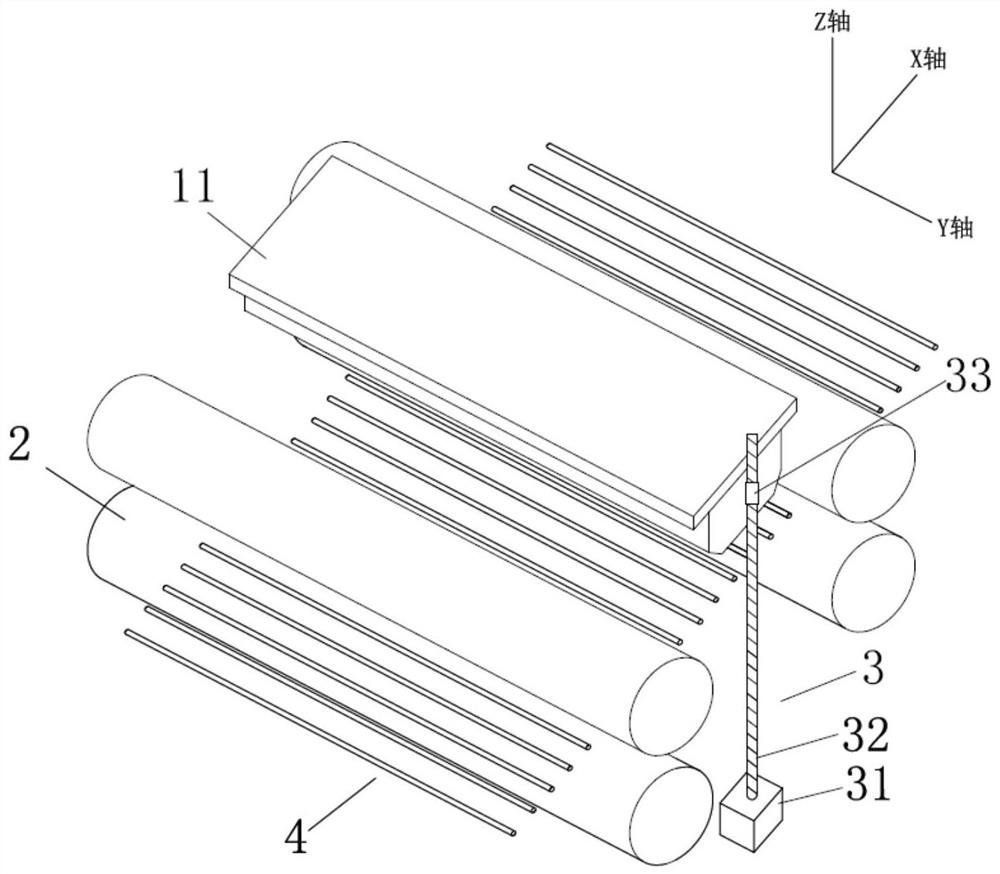

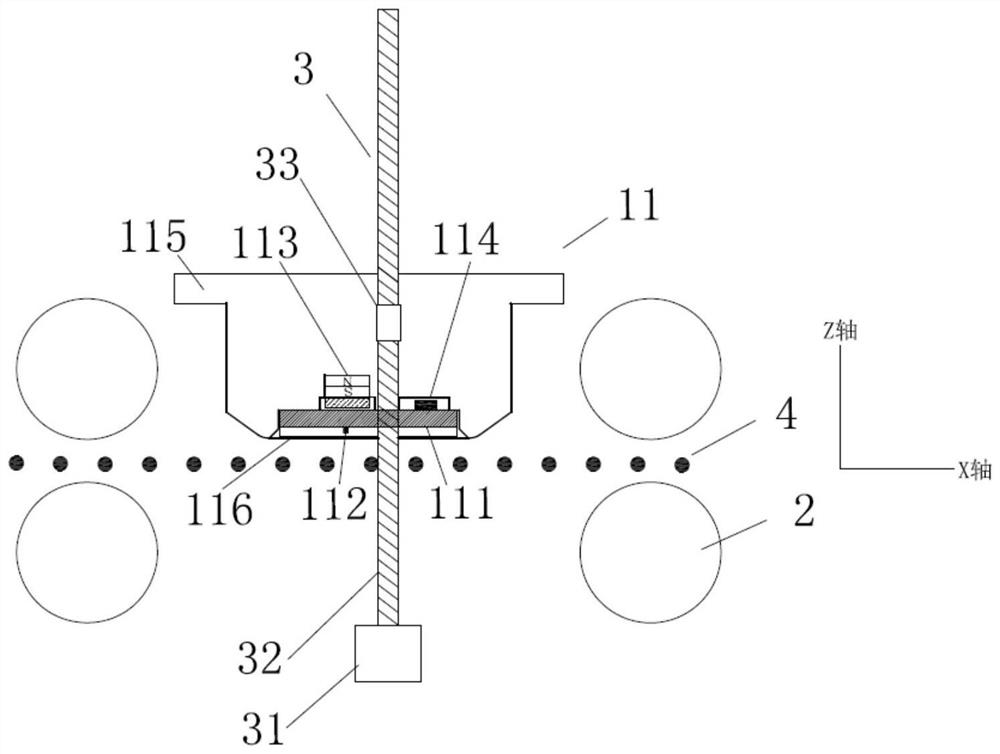

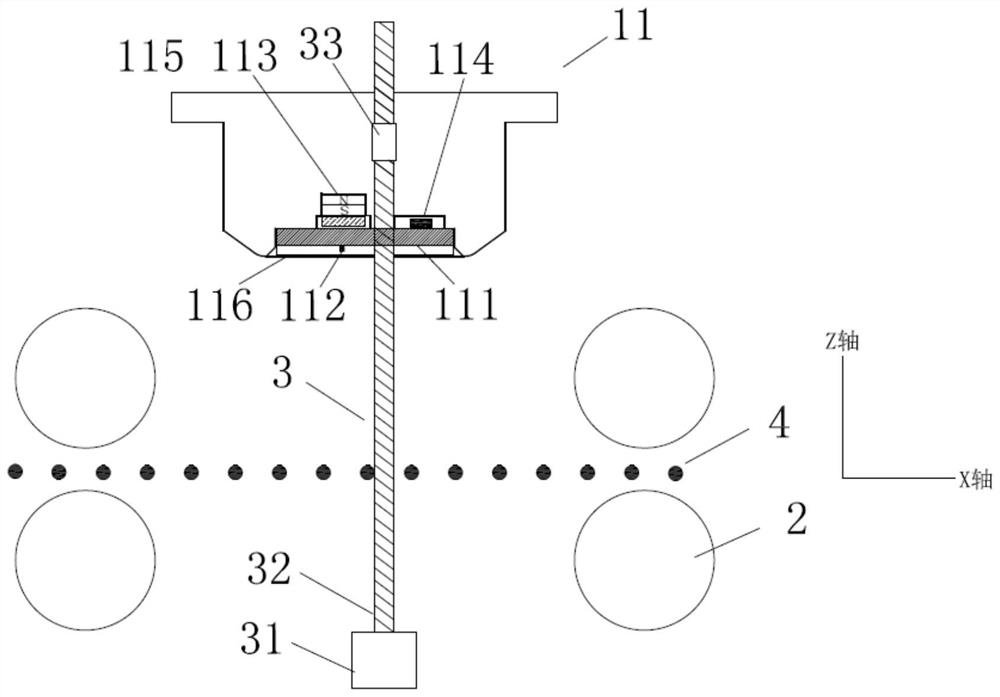

[0084] Such as Figure 1 to Figure 3 As shown, this embodiment provides a steel cord detection and calibration device, including a magnetic sensor module 11, four rollers 2 and a lifting mechanism.

[0085] The magnetic sensor module 11 is arranged directly below the web of the steel cord 4, and includes a substrate 111 made of PCB material. 4320 magnetic sensitive elements 112 are arranged at equal intervals of 0.5 mm to form an effective scanning width of 2160 mm and obtain detection signals and calibration signals, both of which are magnetic field signals, specifically, voltage signals reflecting the magnitude of the magnetic field; The surface of the base plate 111 facing away from the steel cord 4 is provided with a magnetic unit 113 and a processing unit 114. The magnetic unit 113 includes a plurality of magnets arranged at equal intervals along the Y-axis direction. The processing unit 114 communicates with the magnetosensitive The element 112 is electrically connected...

Embodiment 2

[0105] Embodiment 2 provides another embodiment of the steel cord detection and calibration device of the present application, Figure 4 is a perspective view of this embodiment, Figure 5 It is a side view of this embodiment in the detection state, Figure 6 It is a side view of this embodiment in a calibration state.

[0106] Such as Figure 4 to Figure 6As shown, the difference between this embodiment and Embodiment 1 is that the two rollers 2 are located under the steel cord 4 for supporting the steel cord 4, and the two ends of the rollers 2 exceed the edge of the steel cord 4, and the four sets of lifting dies Group 3 respectively corresponds to the four ends of the two rollers 2 , and the receiving member 33 of each group is connected to one end.

[0107] When using the steel cord detection and calibration device of this embodiment to detect and calibrate the steel cord 4, the four motors 31 rotate at the same speed and direction of rotation, driving the two rollers ...

Embodiment 3

[0109] Embodiment 3 provides another embodiment of the steel cord detection and calibration device of the present application, Figure 7 is a perspective view of this embodiment, Figure 8 It is a side view of this embodiment in the detection state, Figure 9 It is a side view of this embodiment in a calibration state.

[0110] The difference between this embodiment and Embodiment 2 is that an opposing magnetic module 12 is added, and the opposing magnetic module 12 and the magnetic sensor module 11 are oppositely arranged on both sides of the steel cord 4, and the two keep a fixed distance of 10 cm, and the opposite The magnetic module 12 includes a facing magnetic unit 121 formed by arranging magnets of a plurality of strong magnetic structures along the Y direction. Inserted and fixed; the steel cord 4 is driven up and down between the magnetic sensor module 11 and the opposing magnetic module 12 under the drive of the roller 2. Obviously, in the above-mentioned embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com