Aviation arc fault damage simulation method based on Fluent software

An arc fault and damage simulation technology, applied in the field of simulation computing, can solve the problems of difficulty in reproducing experimental scenarios and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] Below in conjunction with accompanying drawing and specific embodiment mode, the present invention is described in further detail:

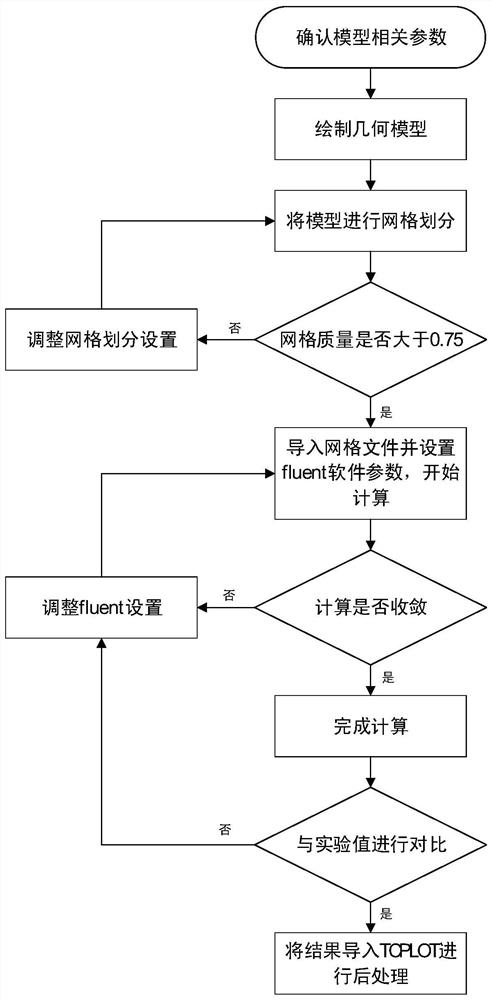

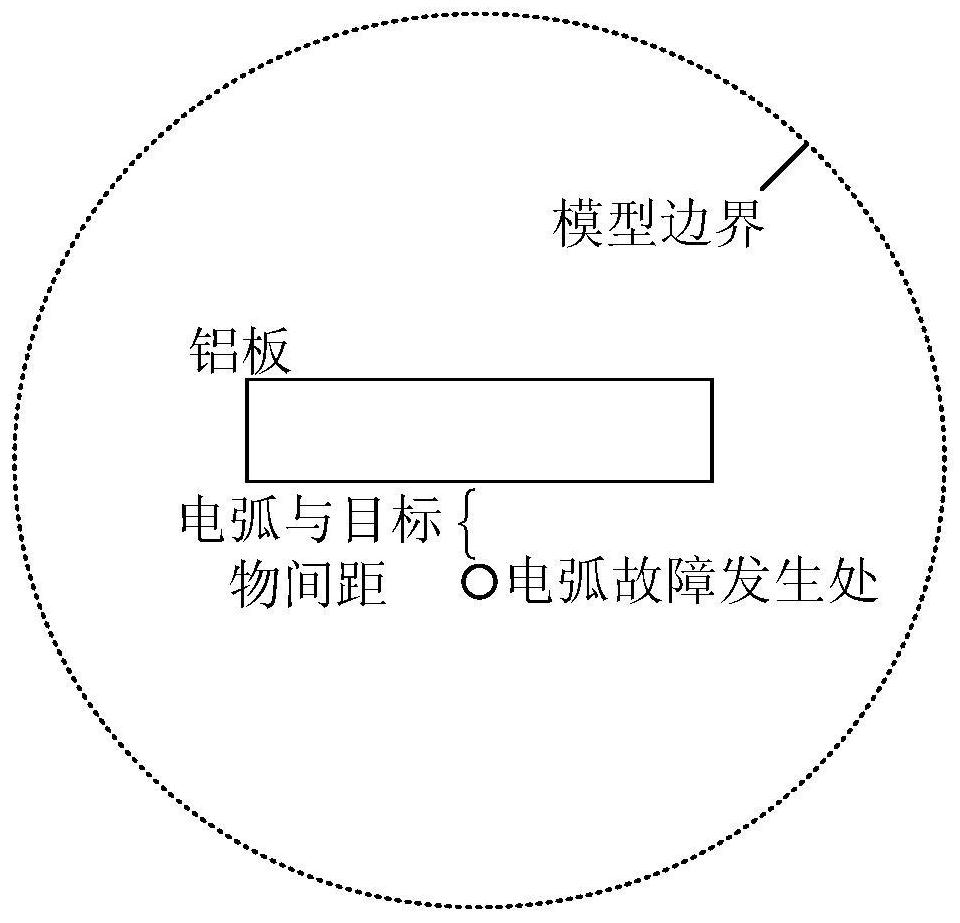

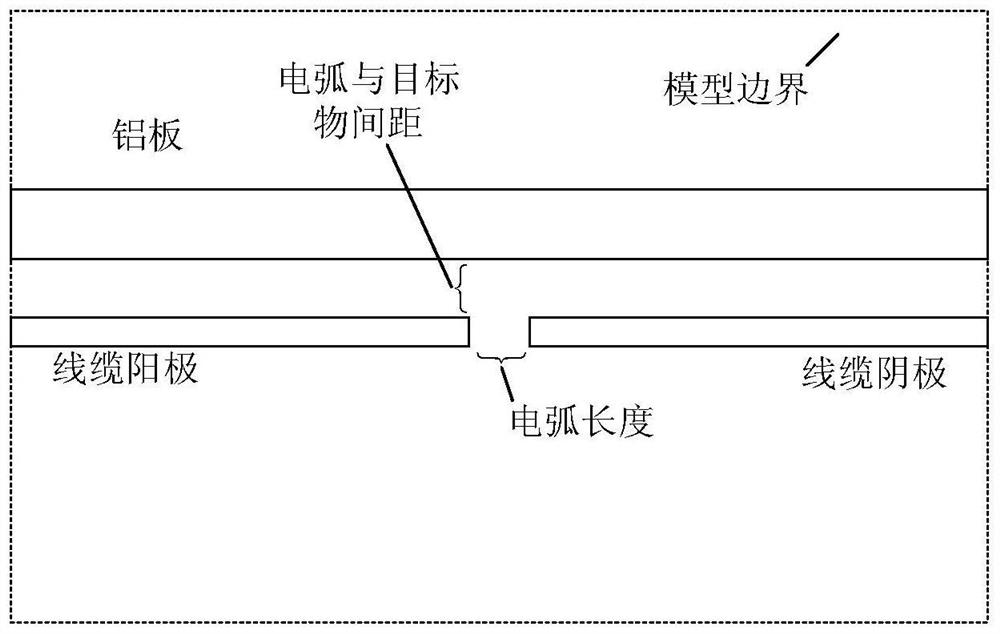

[0024] Such as Figure 1 to Figure 3 As shown, a kind of aviation arc fault damage simulation method based on Fluent software of the present invention comprises the following steps: (1) embodiment is the simulation calculation of the damage situation of aviation arc fault to aluminum plate structure when the current size is 300A. Confirm the size parameters of the place where the aviation arc occurs, including: arc length, cable diameter, aluminum plate thickness, distance between the arc and the aluminum plate; temperature and air pressure when the arc occurs. The length of the arc is 1mm, the diameter of the cable is 0.813mm, the thickness of the aluminum plate is 4mm, and the distance between the arc and the aluminum plate is 0.1mm (regarded as no interval).

[0025] (2) According to the size para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com