RGB-D image-based CLANet steel rail surface defect detection system and method

An RGB image and defect detection technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problem that the deep information is not fully utilized, the detection accuracy and efficiency are lower than the machine vision method, and the image processing technology has not been widely used. application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to facilitate the understanding of the present application, the present application will be described more fully below with reference to the related drawings. The drawings show relatively high-quality embodiments of the present application, but the implementation of the present application is not limited to the embodiments shown in the drawings. These embodiments are provided to facilitate understanding of the disclosure of the present application.

[0060] The invention regards the rail surface defect as a salient target of the rail surface, applies the RGB-D image salience detection algorithm based on deep learning to the rail defect detection, and proposes a new attention mechanism and network structure for RGB -D image saliency detection algorithm to realize surface defect detection of high-speed rail.

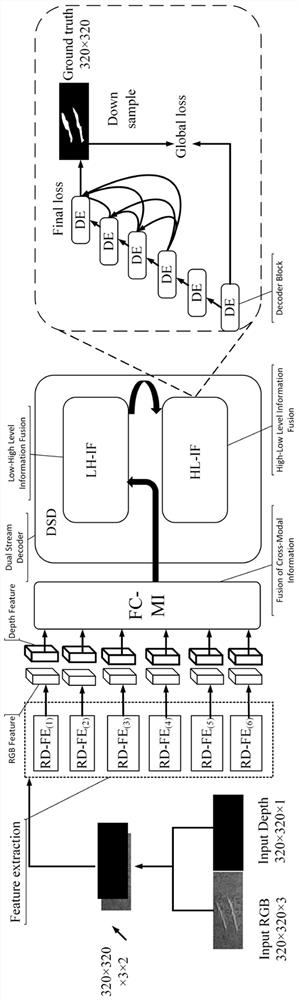

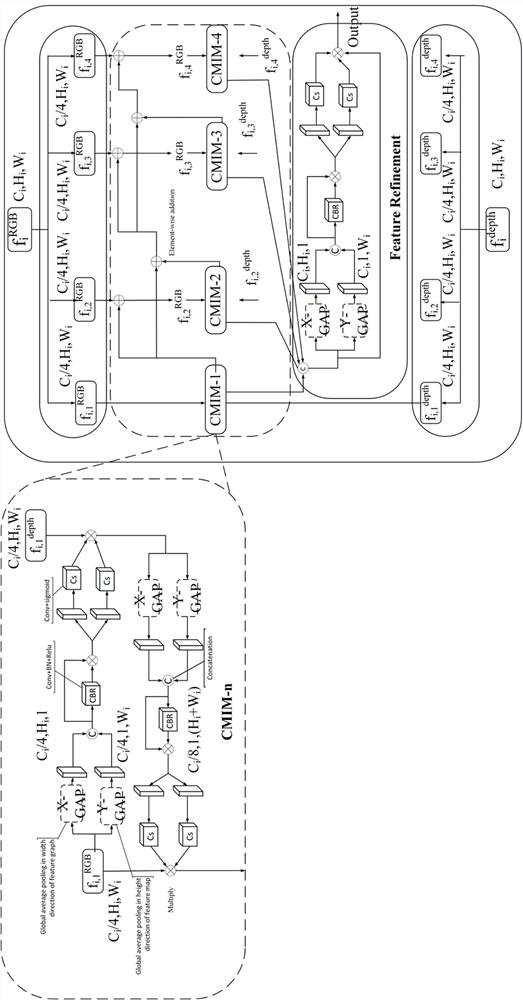

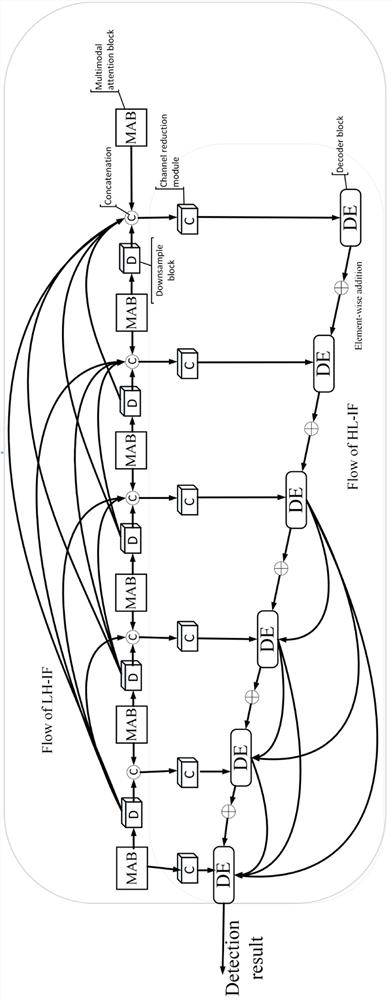

[0061] figure 1 It is a schematic structural diagram of the RGB-D image-based CLANet rail surface defect detection system of the present invention. The R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com