Tab cutting dust removal device and tab cutting dust removal process thereof

A dust removal device and lug technology, which is applied in manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of extremely high cleanliness, pollution, and adhesion on the surface of pole pieces, and improve the cutting efficiency of tabs and surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

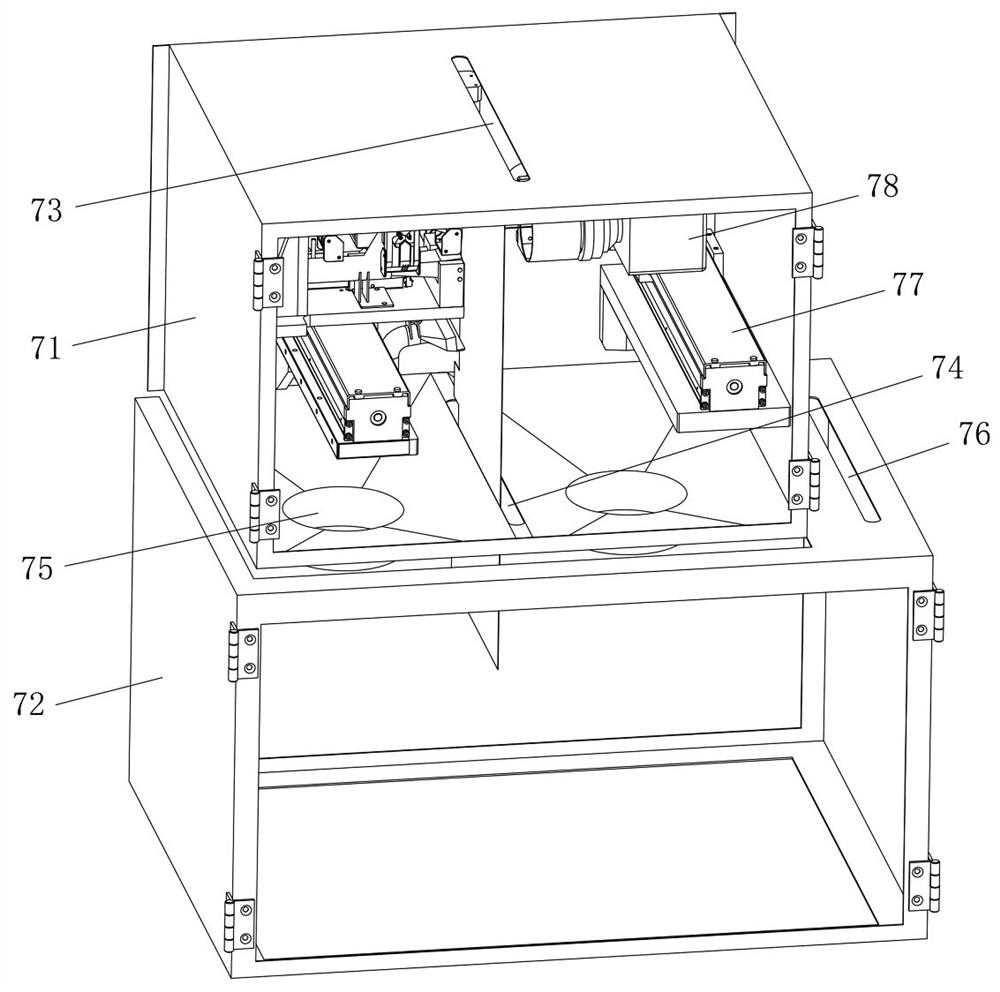

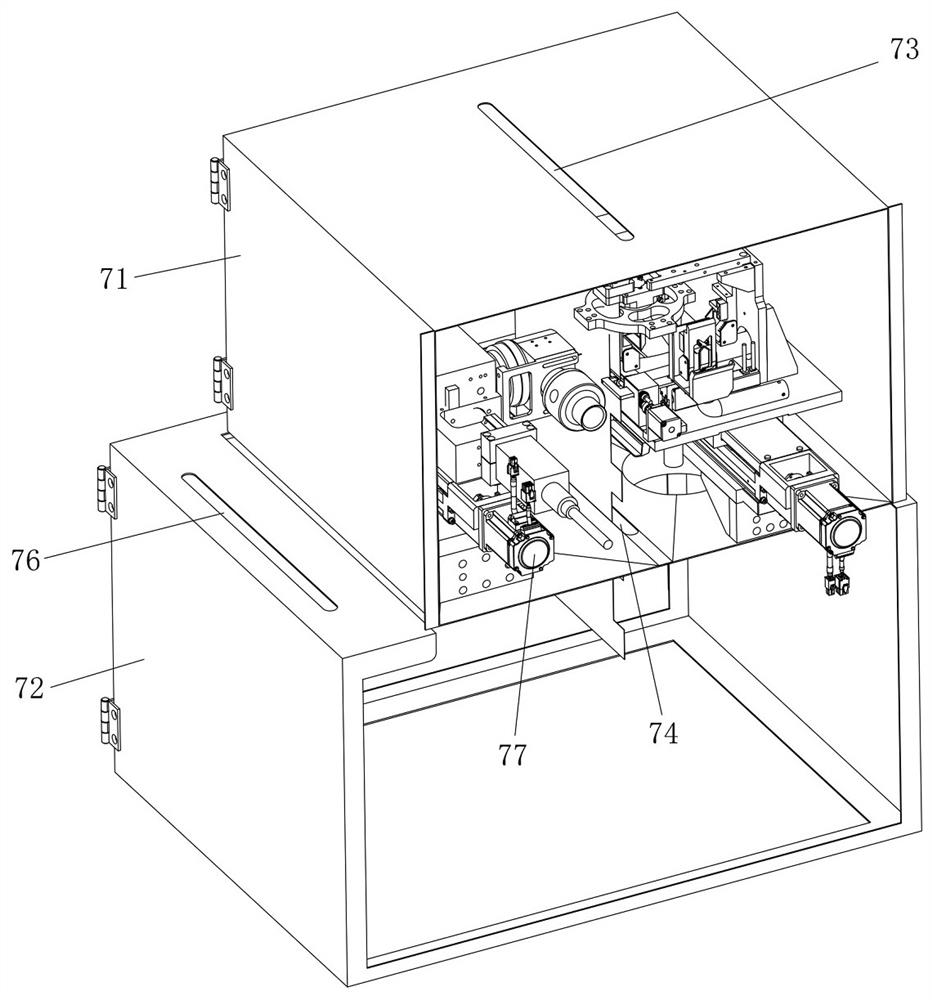

[0030] Such as Figure 1 to Figure 10 As shown, the technical solution adopted by the present invention is as follows: a tab cutting and dust removal device, including a first box body, a second box body, a pole piece entry groove, a pole piece transition groove, a dust removal cover, a pole piece outlet groove and a pole piece. The ear cutting assembly, wherein, the above-mentioned first box body and the second box body are arranged at intervals up and down, and the interior of the two is an installation space; the above-mentioned pole piece entry groove is set on the first box body; the above-mentioned pole piece transition groove and the pole piece outlet The grooves are respectively set on the second box body, and the pole piece transition groove is located at the connecting part of the first box body and the second box body, and the pole piece outlet groove is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com