Apparatus for exhaust gas retreatment

A technology for equipment and exhaust gas, applied in the field of exhaust gas/exhaust equipment, which can solve the problems of nitrogen oxide removal and exhaust gas reprocessing not being optimally solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

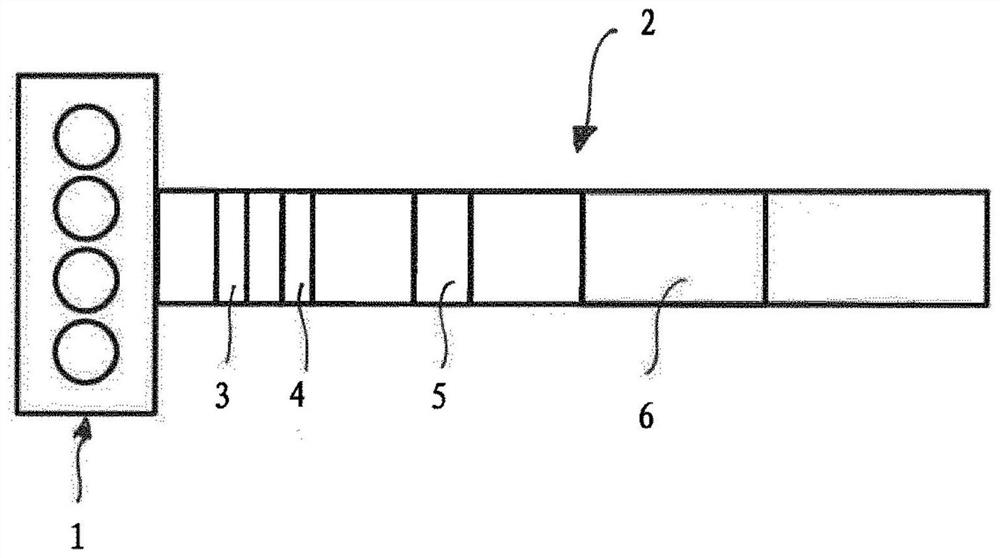

[0024] figure 1 An internal combustion engine 1 is shown. The exhaust gases of the internal combustion engine 1 are conducted into an exhaust duct 2 , which is the flow path for the exhaust gases. A hydrocarbon trap 3 and a nitrogen oxide adsorber 4 are arranged in the flow path 2 . They can also be arranged in reverse order. An electrically heatable heating catalytic converter 5 and then at least one main catalytic converter with reference numeral 6 , which can be, for example, an oxidation catalytic converter or an SCR catalytic converter, are arranged downstream in the direction of flow.

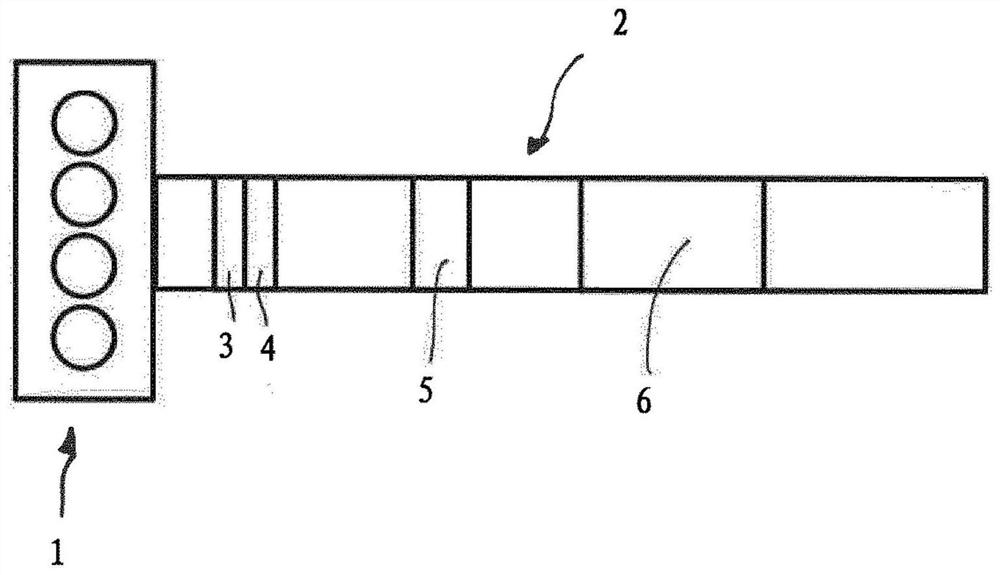

[0025] figure 2 Similar structures are shown, therefore the same reference numerals are used. and figure 1 The difference is that the hydrocarbon trap 3 and the nitrogen oxide adsorber 4 are designed in combination as a common component. Here too, the sequence of the hydrocarbon trap and the nitrogen oxide adsorber can be reversed.

[0026] figure 1 and figure 2 The examples in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com