Fluid valve assembly including valve body having seal retention feature

A technology of valve body and fluid valve, applied to parts in contact between valve elements and valve seats, cocks including cut-off devices, multi-way valves, etc., can solve the problem of reducing valve operating life, excessive wear of seals and valve bodies, etc. problems, to increase reliability and durability, reduce wear, and minimize wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

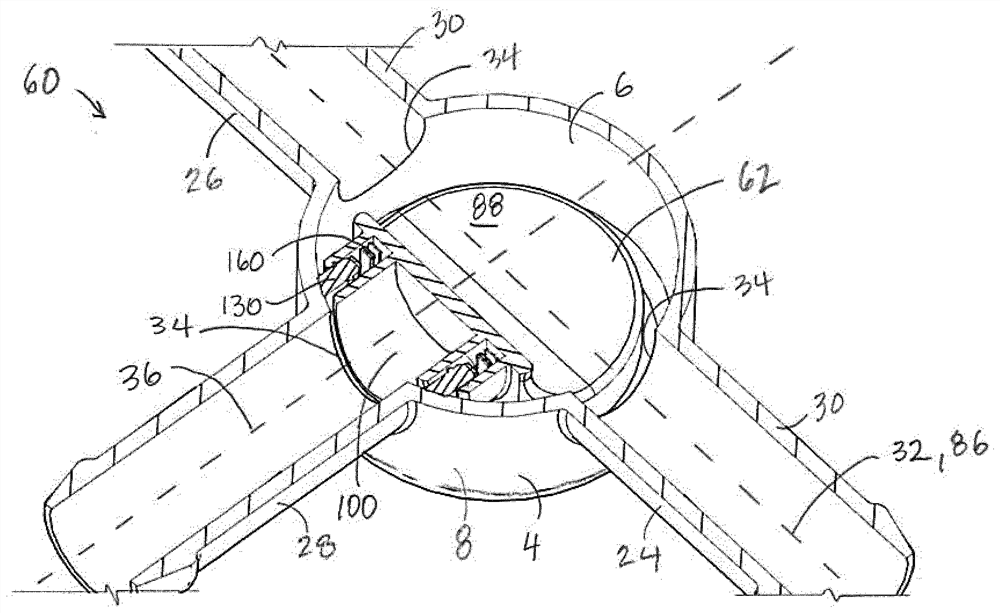

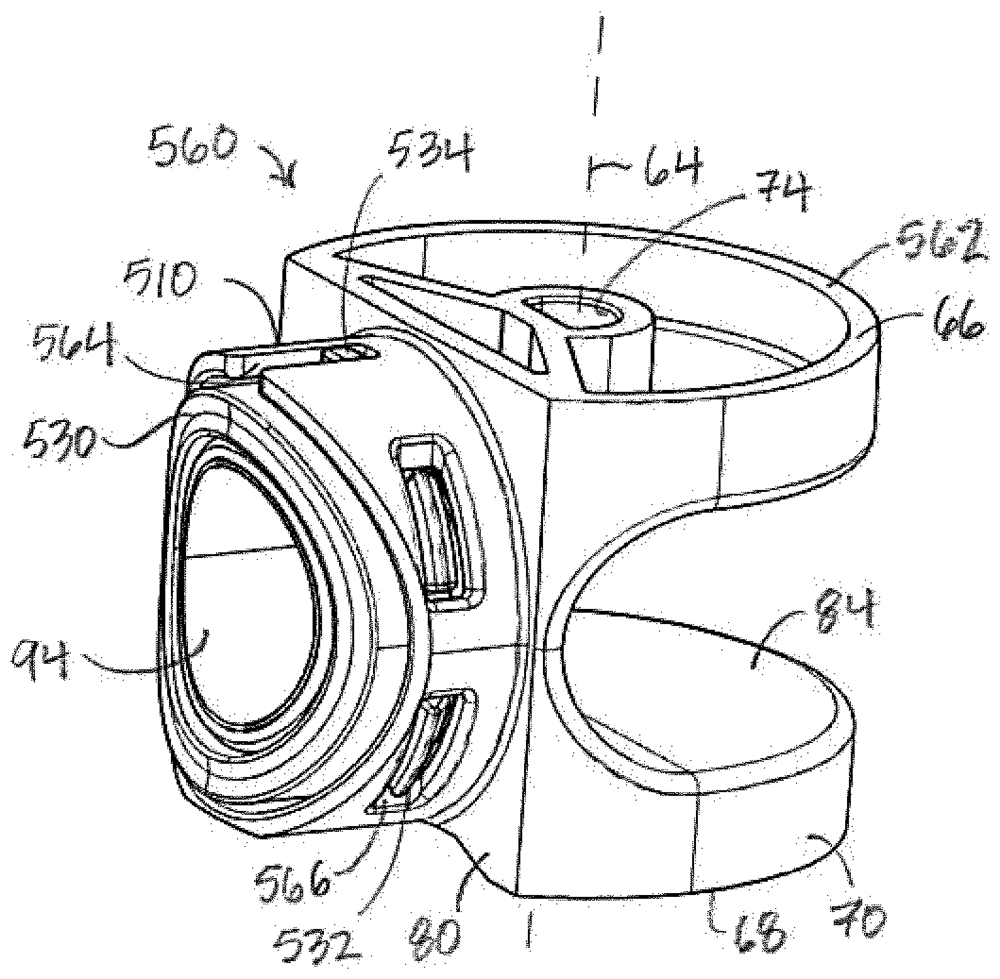

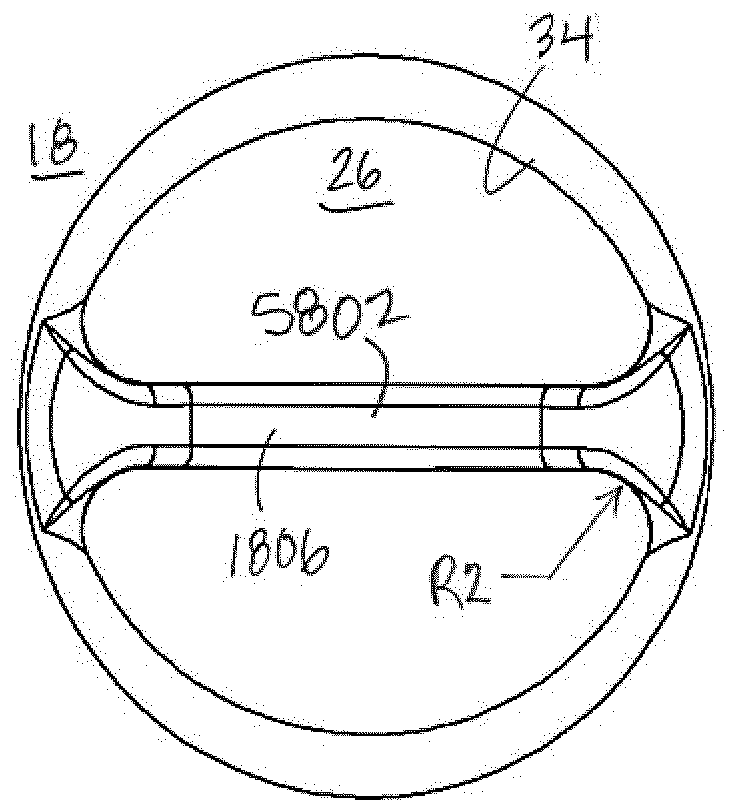

[0083] refer to figure 1 – Figure 4 , the fluid valve assembly 1 includes a fluid valve 2 and an actuator 200 for actuating the fluid valve 2 . The fluid valve assembly 1 may be used, for example, to control the distribution and flow of coolant in a vehicle cooling system. Fluid valve 2 is a rotary plug valve. The rotary plug valve 2 is mounted to the actuator housing 202 and includes a plug assembly 60 seated in the valve body 4 and rotatable relative to the valve body 4 about an axis of rotation 64 . Valve body 4 includes three valve ports 24 , 26 , 28 and the rotational orientation of plug assembly 60 relative to valve body 4 is set via actuator 200 . The rotational orientation of the plug assembly 60 relative to the valve body 4 determines one or more fluid flow paths through corresponding ones of the valve ports 24 , 26 , 28 . The rotary plug valve 2 has a single elastomeric valve seal 130 that provides a fluid-tight seal between the valve body 4 and the plug assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com