Dynamic beam deflection and shaping for laser processing

A laser processing, laser beam technology, applied in the field of optical systems, which can solve the problems of affecting the sensor, extending the beam path, and expensive to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

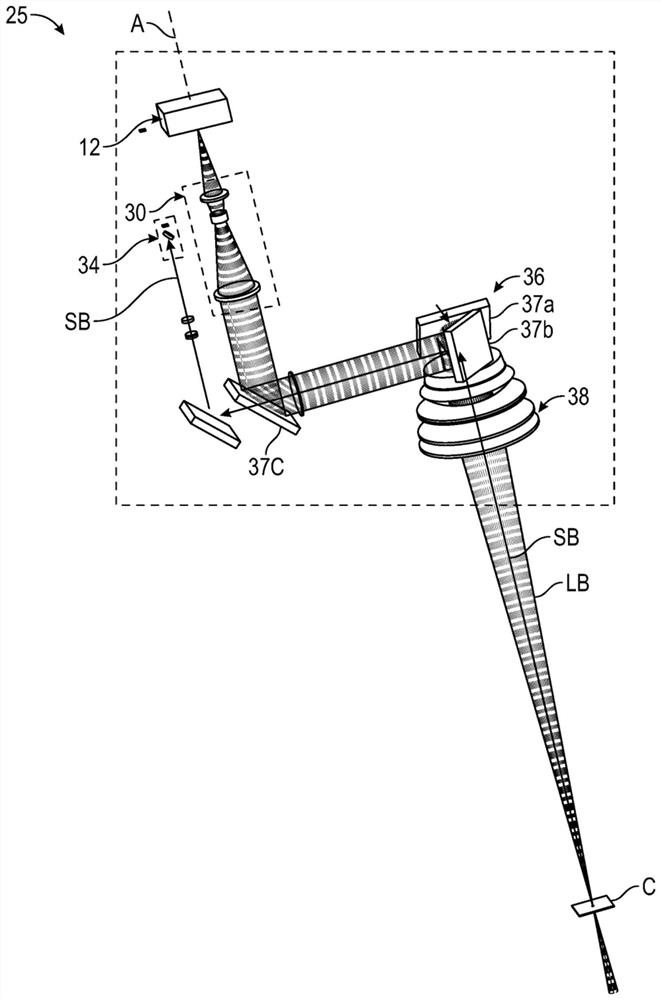

[0024] The present disclosure generally relates to optical systems and related art for uses of optical systems. More particularly, but not exclusively, the present disclosure relates to systems and methods for inducing wobbles in laser beams. In one aspect, the optical systems disclosed herein may be used in conjunction with laser cut components, laser fabricated components, additive manufacturing, or laser welding or otherwise joining two or more components using a laser, among other variations. Although embodiments are described in the context of laser beam swings that may be used in these processes, it will be appreciated that embodiments disclosed herein may be useful in other fields and / or operating environments where the functionality disclosed herein may be beneficial. used in. Accordingly, the scope of the present invention should not be construed as limited to the exemplary implementations and operating environments disclosed herein.

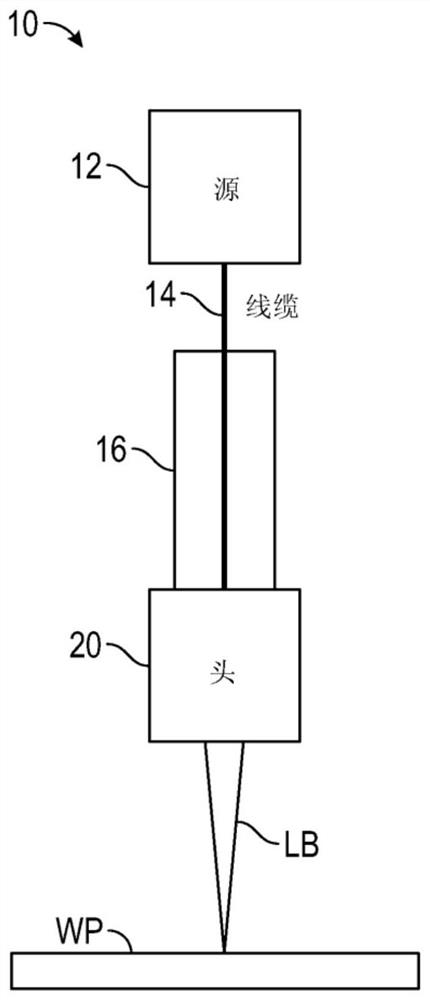

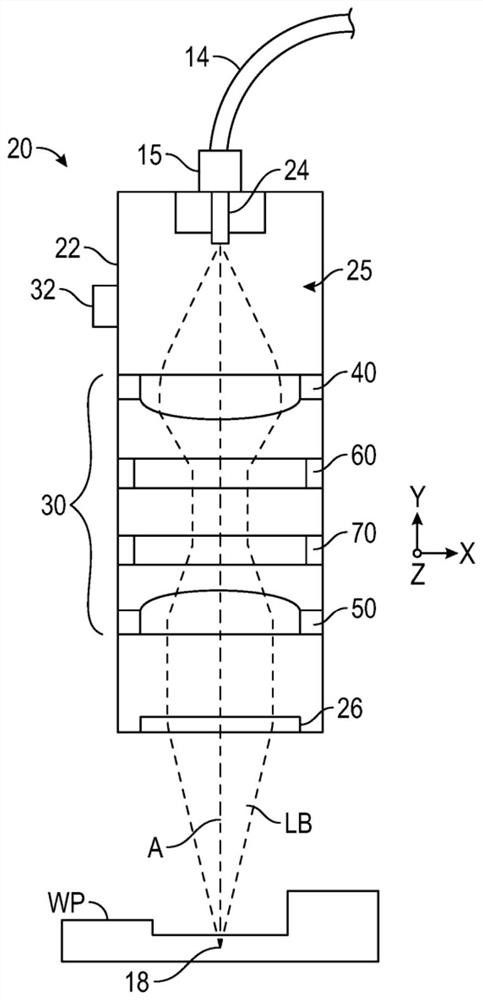

[0025] Figure 1A A laser deli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com