High-temperature gas transmission drainage mechanism

A drainage mechanism and gas transmission technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of affecting the heating effect of high-temperature steam on the roller, unable to maintain the stability of the roller air pressure, sealing bearing and large wear, etc. It achieves the effect of facilitating inspection, maintenance and installation, compact structure, and not easy to loosen and leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

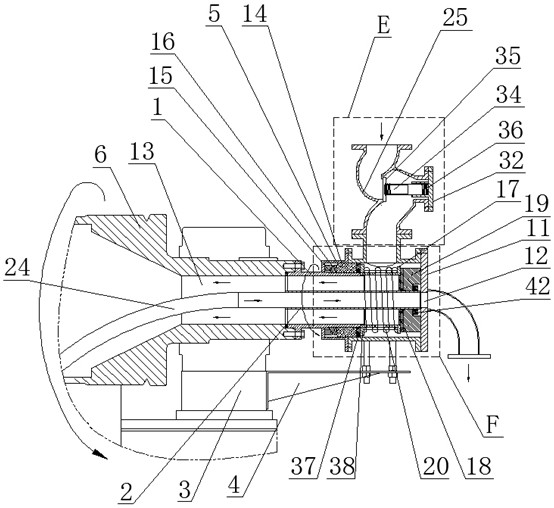

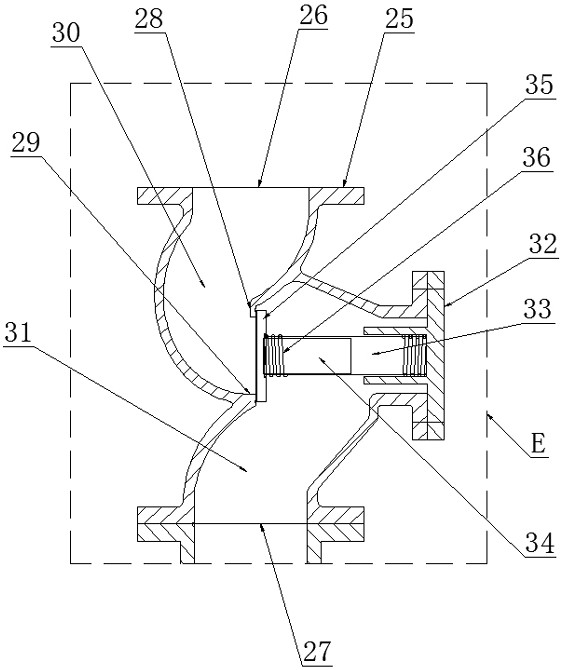

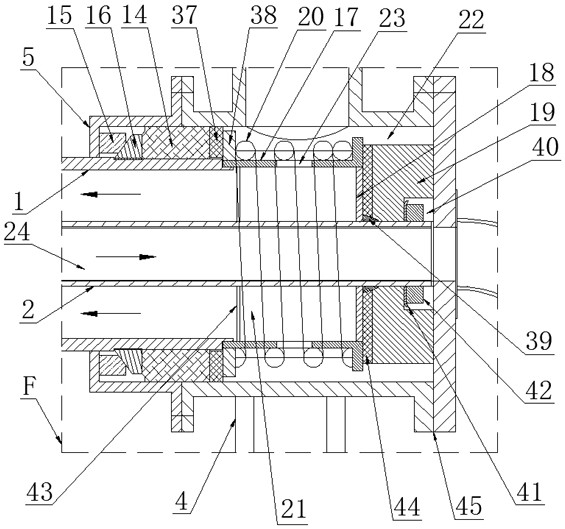

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the described high-temperature gas transmission and drainage mechanism includes: a rotating outer pipe 1, a fixed inner pipe 2, and a support frame 4 for fixed connection with the roller support 3, and the support frame 4 supports The inner hollow shell 5 is provided with a front mounting port 7 close to the roller 6, a rear mounting port 8 far away from the roller 6, and a steam inlet between the front mounting port 7 and the rear mounting port 8 on the shell 5. Port 9, a check mechanism is installed on the steam inlet 9 of the housing 5, the check mechanism can only allow high-temperature steam to flow into the housing 5 from the steam inlet 9 and not allow the high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com