Production method of nodular iron casting and nodular iron casting prepared by adopting method

A nodular cast iron and production method technology, which is applied in the field of nodular cast iron, can solve the problems of inoculation decline, lower elongation of toughness index, and long pouring time, etc., and achieve the goals of improving the consistency of metallographic structure, reducing the quantity, and prolonging the effective time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

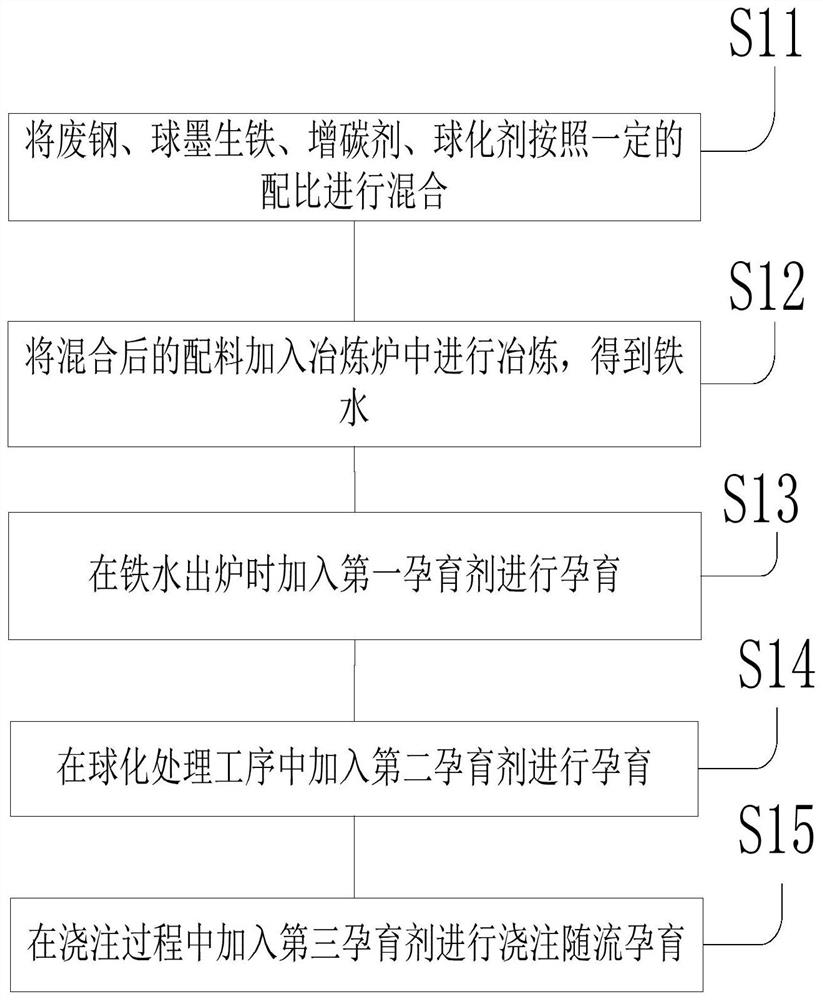

Method used

Image

Examples

Embodiment 1

[0049] Taking QT400 as an example, scrap steel, nodular pig iron, recarburizer, and nodulizer are mixed according to a certain ratio. Among them, the weight of scrap steel is 0.9 tons, the weight of nodular pig iron is 5 tons, and the weight of carburizer is 2.2 tons. The weight of the nodulizer is 2 tons, the weight of the first inoculant is 0.03 tons, the weight of the second inoculant is 0.03 tons, and the weight of the third inoculant is 0.2 tons.

[0050] The pouring temperature is 1310 degrees Celsius.

[0051] The heat treatment temperature is 620 degrees centigrade, the heat treatment holding time is 1.5 hours, and the heating rate and cooling rate are carried out using the parameters in the prior art.

[0052] The composition of the ductile iron casting obtained by this method is: 3.8% carbon, 2.7% silicon, 0.4% manganese, 0.8% magnesium, 4% rhenium, 1% calcium, and 1% barium.

[0053] The tensile strength at room temperature is 550MPa, the impact performance at room...

Embodiment 2

[0055]Taking QT500 as an example, mix steel scrap, ductile iron, recarburizer, and nodulizer according to a certain ratio. The weight of scrap steel is 1.5 tons, the weight of nodular pig iron is 8 tons, and the weight of carburizer is 3 tons. 1. The weight of the nodulizer is 2.5 tons, the weight of the first inoculant is 0.02 tons, the weight of the second inoculant is 0.035 tons, and the weight of the third inoculant is 0.2 tons.

[0056] The pouring temperature is 1310 degrees Celsius.

[0057] The heat treatment temperature is 620 degrees centigrade, the heat treatment holding time is 1.5 hours, and the heating rate and cooling rate are carried out using the parameters in the prior art.

[0058] The tensile strength at room temperature is 640 MPa, the impact performance at room temperature is 120 joules, and the elongation is 35%. Compared with the room temperature tensile strength of 520 MPa and the elongation of 24% in the prior art, there is a significant improvement. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com