Method for accurately controlling Als content of high-magnetic-induction oriented silicon steel slab

A technology with high magnetic induction orientation and precise control, applied in the field of metallurgy, it can solve the problems of prolonged processing time, unable to meet the fast pace, high production capacity, accompanied by the end of pouring, etc., and achieve the effect of reducing oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

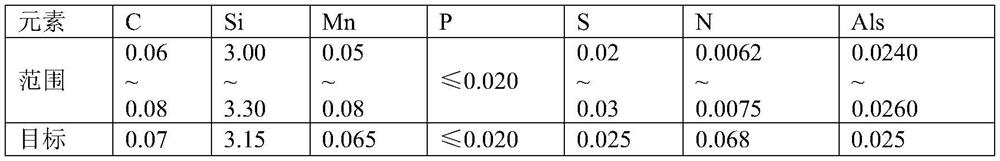

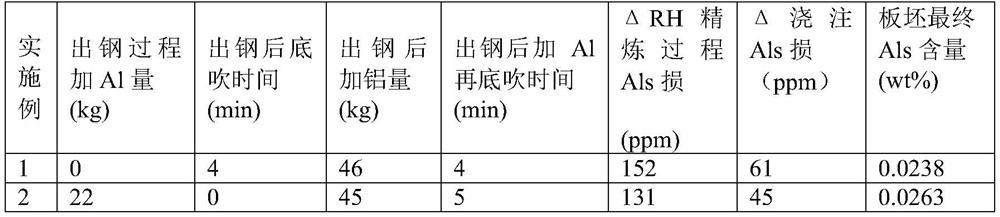

[0035] In the present embodiment, the steel species is high magnetic induction silicon steel, and its main chemical composition requirements and target components are shown in Table 1. According to the main ingredients of the Name 1, the replacement of 80 tons of the replacement of 8-furnace steel, the converter smelted steel 20,940 seconds, the amount of aluminum and the alloying process after the steel, and the steel water was subjected to 2 ALS component fine-tuning in RH. After the end of the RH refining, the ALS, the RH refining process ALS is damaged before the steel water, and the casting process is 9M. 3 The argon circulation of / h is protected, and the slab after the casting is carried out in accordance with the present invention.

[0036] In this example, 1-4 is contrast. Since the steel slag is not in accordance with the present invention, the steel slag is strong and the difference is different, resulting in a large loss of RH refining process and casting process ALS ...

Embodiment 2

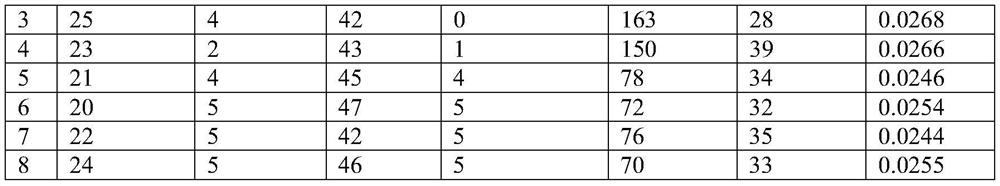

[0043] In this embodiment, the steel species is high magnetic induction silicon steel, and its main chemical composition requirements and target components are shown in Table 3. The main ingredients of the Name 3 were smelted in the replacement of 20 furnace steels in the replacement of 200 tons of nominal capacity. Smelting process converted steel 30 seconds, quantitatively adding aluminum 33kg / furnace, and the steel is added to the bottom of the wire after the steel and other alloys are blown for 4 min, and the aluminum wire is 85kg / furnace, and then the bottom is blown well for 5 min. Steel water to RH refining treatment processed end-like composition after completion of secondary component fine-tuning, end-like ALS detection results, according to high magnetic alternating silicon steel slab ALS target ingredients and RH refining process aluminum loss after calculation The until the casting is cast, in fact, the amount of aluminum is added to the example: casting the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com