System for synthesizing methane by co-electrolyzing H2O and CO2 through fuel cell

A technology for synthesizing methane and fuel cells, which can be used in fuel cells, fuel cell additives, and fuel cell heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

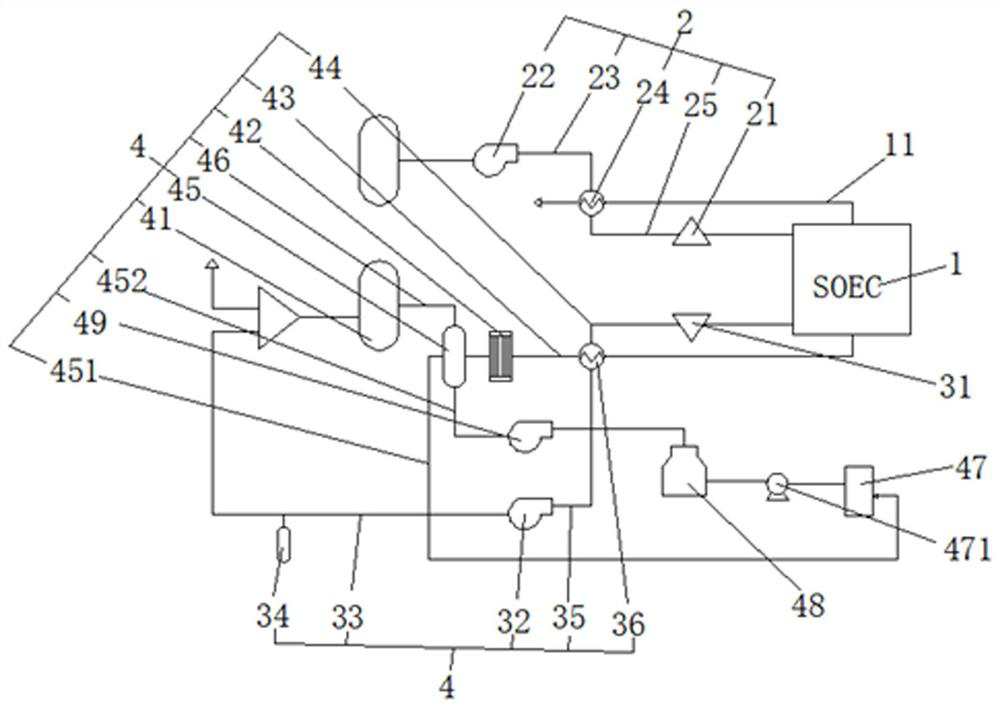

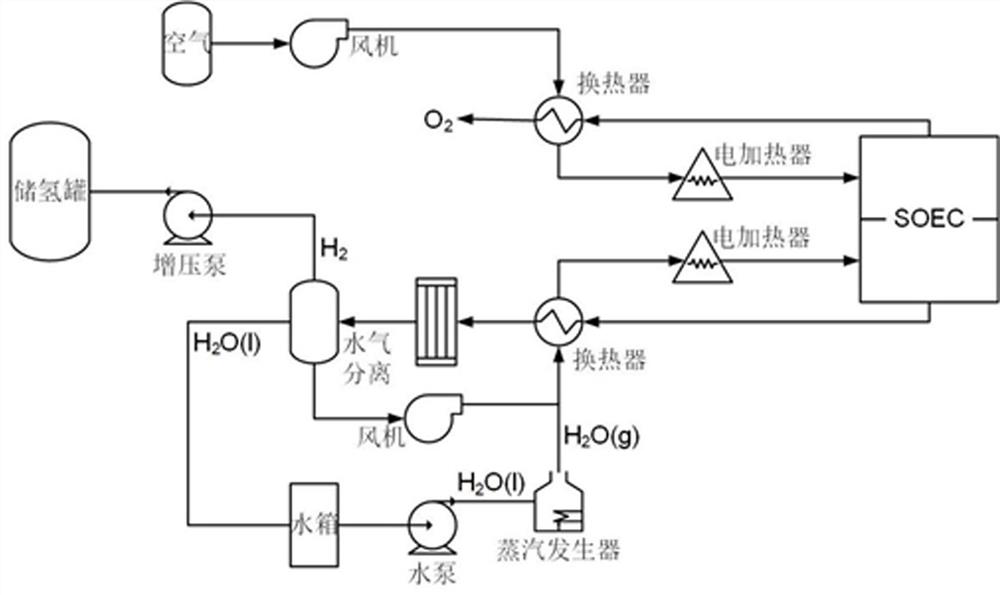

[0021] Examples, please refer to Figure 1-2 , a fuel cell co-electrolysis of H 2 O and CO 2 Synthetic methane system, including SOEC1, air compression heating system 2, circulating hydrocarbon compensation system 3 and methane preparation system 4;

[0022] The air compression heating system 2: After the air is introduced, it is heated by the first electric heater 21 and then introduced into SOEC1 to electrolyze CO and O 2 , in the O 2 discharge;

[0023] The circulating hydrocarbon compensation system 3: the remaining CO and CO in the process of evaporating water and preparing methane 2 After being heated by the second electric heater 31 together with water vapor, it is introduced into SOEC1 for electrolytic hydrogen replenishment;

[0024] The methane preparation system 4: CO, H after electrolysis in SOEC1 2 Separated with water vapor to produce CO through the methanation reactor 41 2 and CH 4 Circulation and discharge are in progress.

[0025] Please refer to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com