Efficient drying system for montmorillonite powder production

A technology of montmorillonite powder and drying system, which is applied in drying chamber/container, drying cargo handling, drying solid materials, etc., can solve the problems of affecting the drying process of powder products, slowing down the production progress, low income, etc., to ensure production The effect of orderliness, waste reduction and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

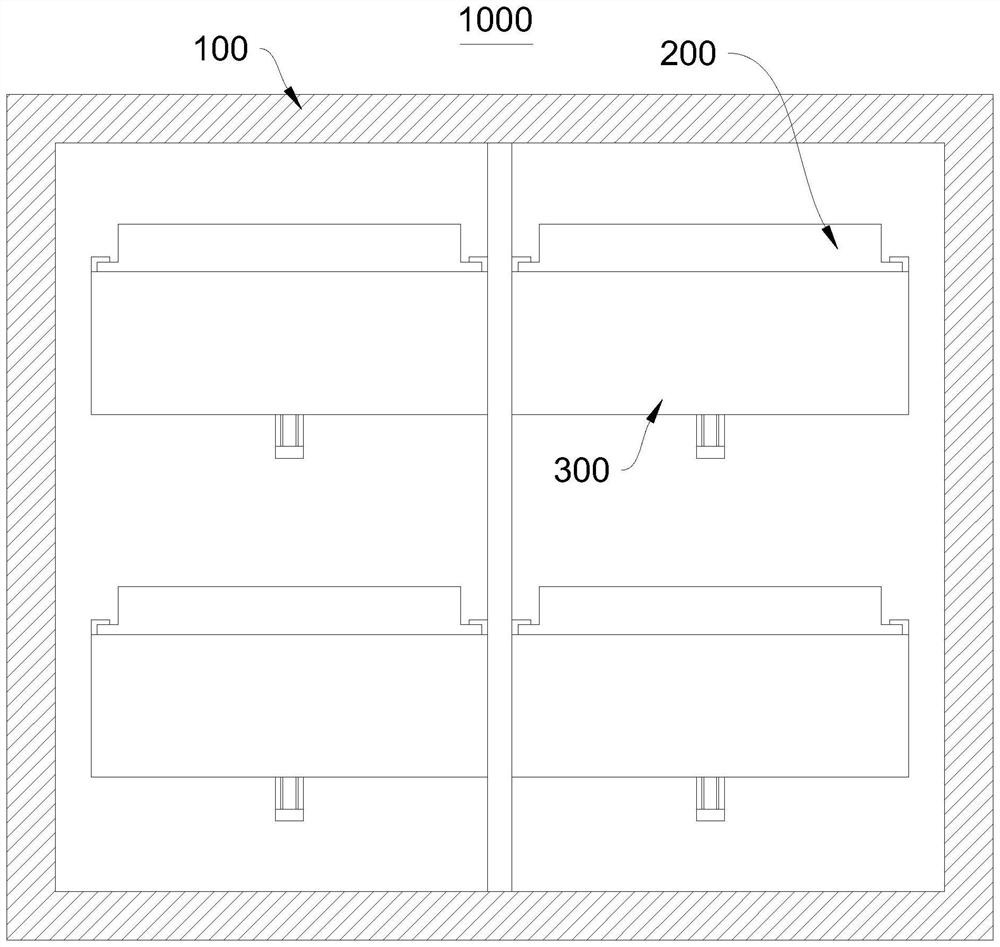

[0044] Please refer to Figure 1 to Figure 6, this embodiment provides a high-efficiency drying system 1000 for the production of montmorillonite powder.

[0045] The insulated box 100 has a temperature raising component and a temperature control component, which can maintain the temperature near the set temperature. The vacuum component (not shown in the figure) communicates with the incubator 100, and the vacuum component can provide a certain degree of vacuum for the incubator 100, so as to facilitate the sufficient drying of the montmorillonite powder and to fully discharge the moisture.

[0046] The bearing base 300 is arranged in the incubator 100 and is arranged and distributed in the incubator 100 .

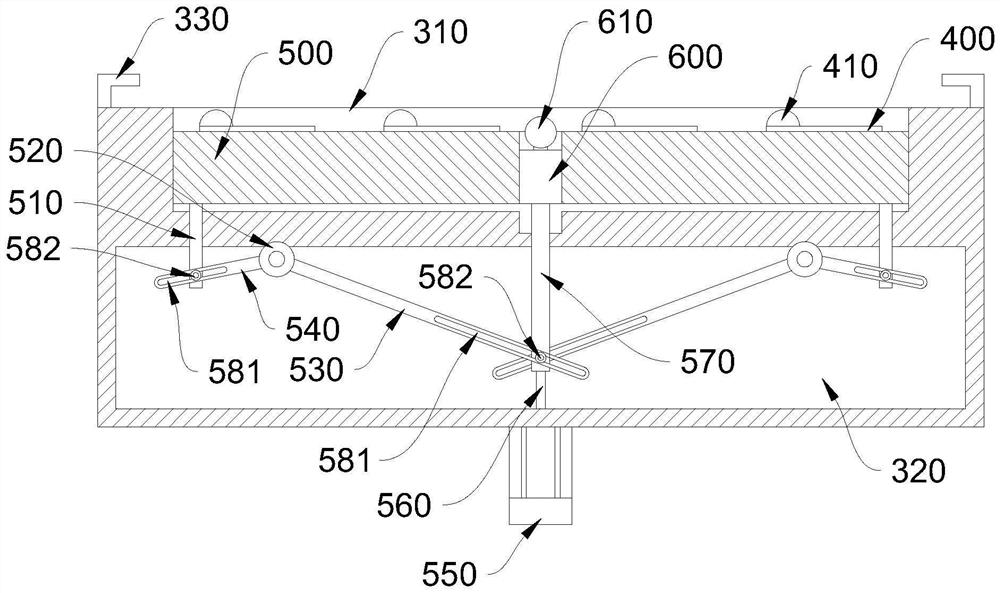

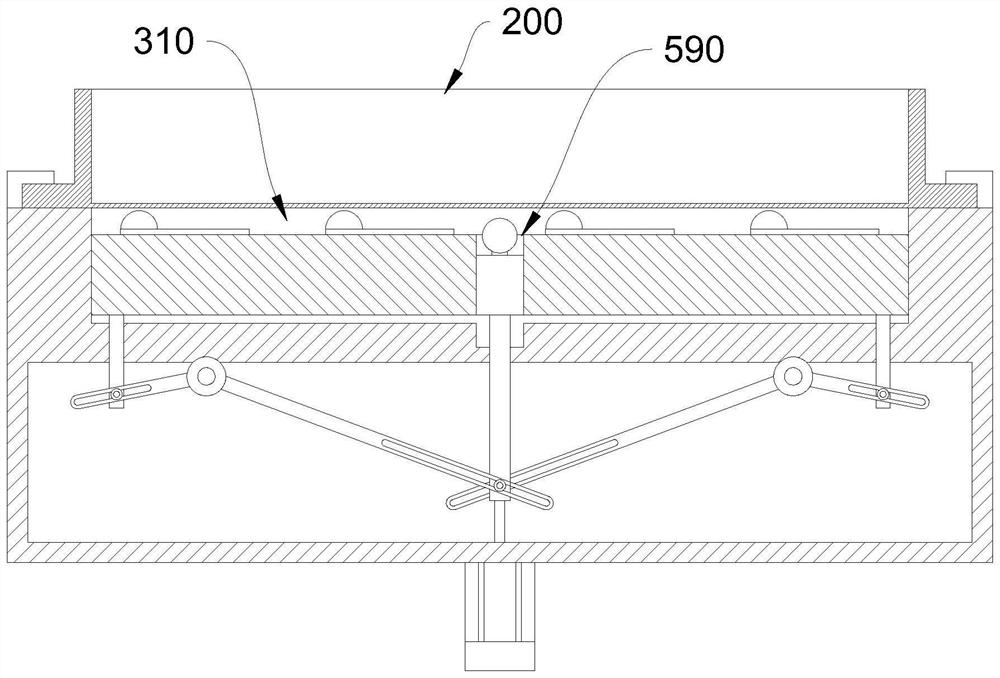

[0047] The bearing surface of the bearing base 300 is provided with an installation groove 310 , and the installation groove 310 is formed by the depression of the bearing surface of the bearing base 300 . The rotating part 400 is installed in the installation groove 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com