Hub test bed and hub test method

A technology of a test bench and a test bench, which is applied in the field of automobile manufacturing, can solve problems affecting the development progress of new products, affecting the traceability of wheel hub tests, and poor overall stability of wheels, and achieves uniformity in promotion, simple structure, and ease of production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

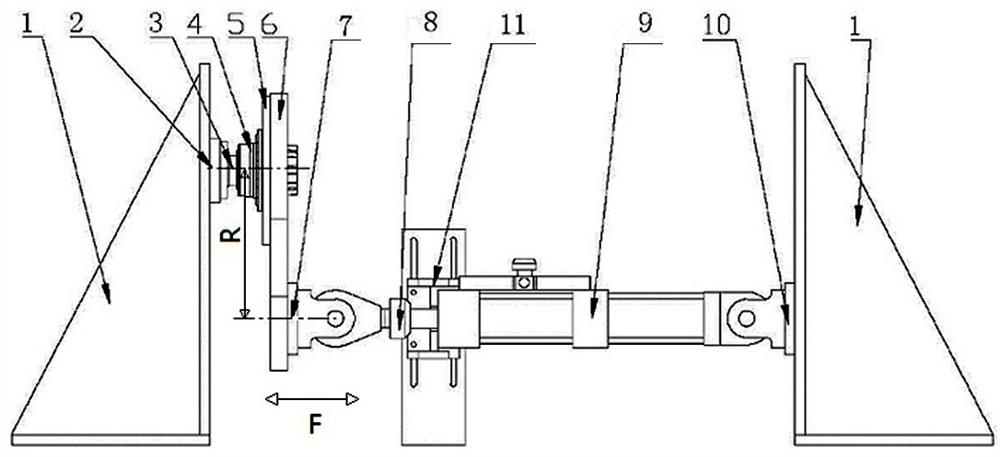

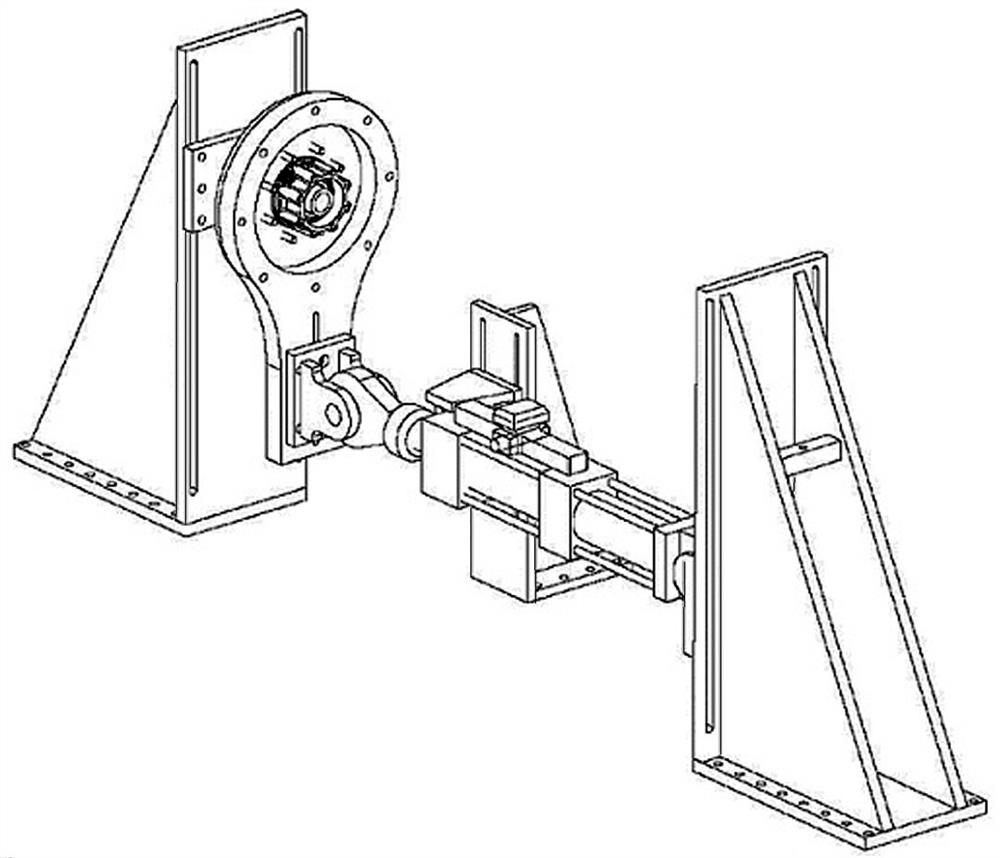

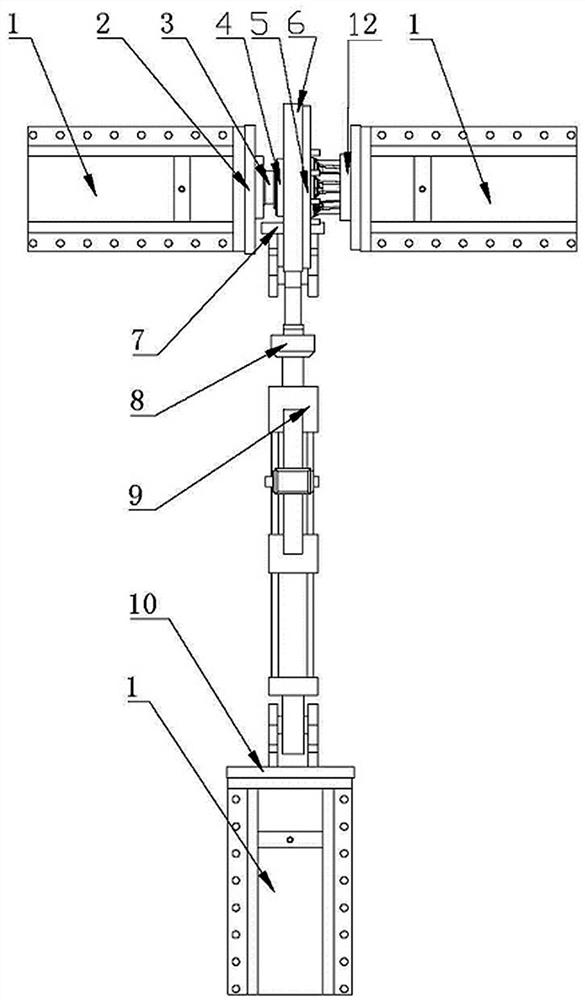

[0032] figure 1 , figure 2 , image 3 with Figure 4 The hub test bench includes hub bending fatigue test bench and hub radial fatigue test bench. Such as figure 1 with figure 2 As shown, in the wheel hub bending fatigue test, the wheel hub bending fatigue test bench is used. The wheel hub bending fatigue test bench includes two reaction seats 1 arranged on the same horizontal line, and one of the reaction seats 1 is set on the end face There is a shaft tube mounting plate 2, the flange end face of the shaft tube 3 is connected with the shaft tube mounting plate 2 and fixed vertically on the reaction seat 1; On the force arm plate 6, the installation of the wheel hub assembly 4 and the shaft tube 3 conforms to the torque specified in the design drawings. Tighten the wheel hub bearing fastening nuts, the tire bolt distribution circle of the wheel hub mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com