Wood board surface processing quality control method based on machine vision

A technology of surface processing quality and machine vision, applied in instruments, image data processing, computing, etc., can solve the problems of different degrees of peeling, complexity, high cost of data acquisition and labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

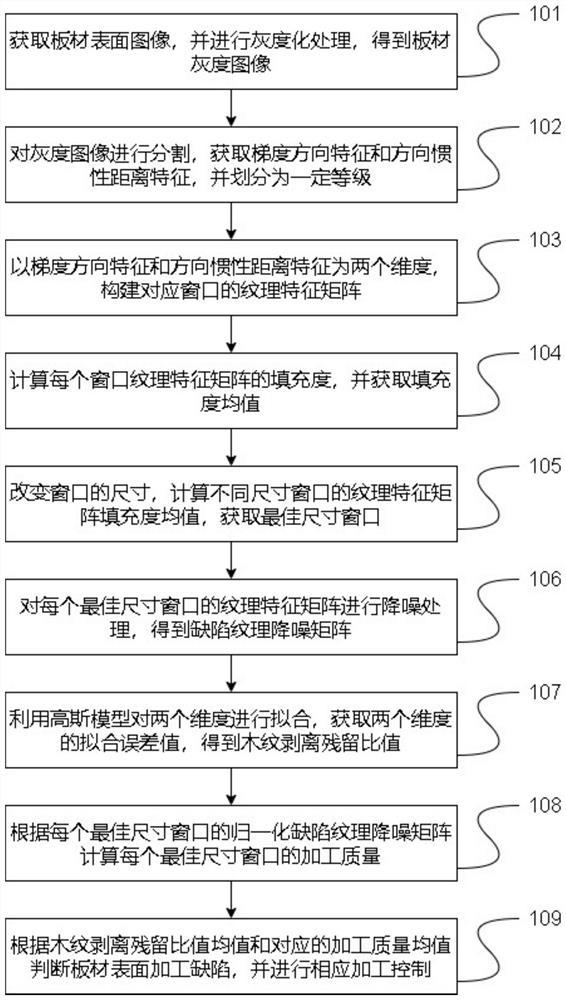

[0055] like figure 1 As shown, a kind of machine vision-based wood panel surface processing quality control method structure schematic diagram of the embodiment of the present invention is provided, including:

[0056] 101. Obtain the surface image of the board, and perform grayscale processing to obtain a grayscale image of the board.

[0057] In this embodiment, a camera is used to obtain an RGB image of the cutting surface of the chord-cut plate substrate product, and convert it into a grayscale image.

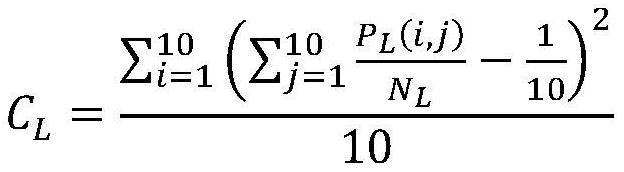

[0058] 102. Sliding the grayscale image with a set window, obtaining the gradient direction feature and the direction inertial distance feature of all point pairs in each window, and dividing the gradient direction feature and the direction inertial distance feature into A certain level.

[0059] For the texture existing on the surface of the chord-cut plate, after analyzing it, it can be seen that the texture has surface texture extensibility and anisotropy, that is, the...

Embodiment 2

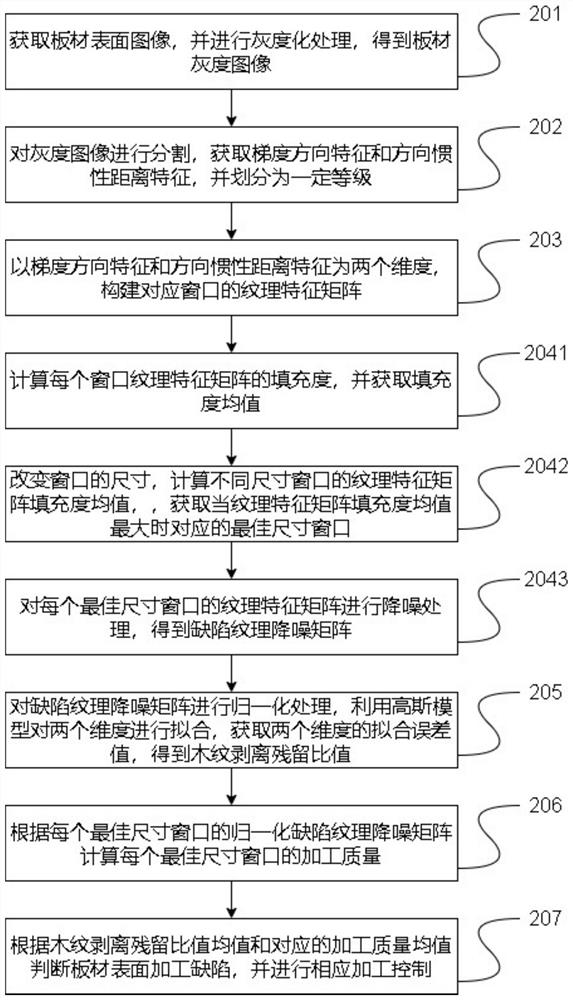

[0089] like figure 2 As shown, another kind of machine vision-based wood panel surface processing quality control method structure schematic diagram of the embodiment of the present invention is provided, including:

[0090] 201. Obtain the surface image of the board, and perform grayscale processing to obtain a grayscale image of the board.

[0091] The application process of this embodiment is to set the camera to collect the surface image of the particleboard base material before the material inlet of the veneer assembly line, and process the collected image.

[0092]202. Perform a sliding window on the grayscale image with a set window, obtain the gradient direction feature and the direction inertial distance feature of all point pairs in each window, and divide the gradient direction feature and the direction inertial distance feature into A certain level.

[0093] Calculate the gradient of the grayscale image, and use the sobel operator to calculate the gradient g in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com