Electric heating element for large-flow high-temperature high-pressure high-speed gas environment and processing method

An electric heating element, high temperature and high pressure technology, which is applied in the field of hypersonic wind tunnel test equipment, can solve problems such as weak installation, electric heating tube installation, difficulty in fixing, and insufficient airflow temperature, so as to improve reliability and service life, reduce The risk of over-temperature damage and the effect of reducing the temperature of the solder joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

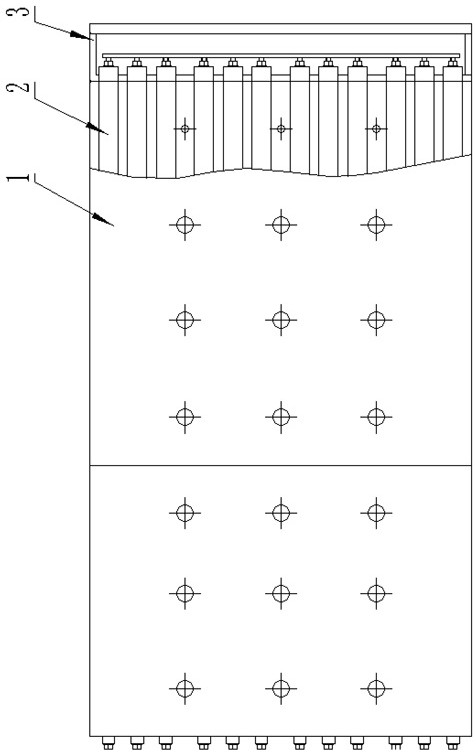

[0068] The electric heating element of this embodiment adopts such as Figure 4 The traditional electric heating tube shown is a self-insulating metal tubular electric heating element, which is composed of a stainless steel cladding tube, crystalline magnesia sand, heating wire, lead-out head, and internal connecting piece. The quantity of electric heating tube 2 is 12, is divided into 3 groups, each group has 4, the diameter of electric heating tube is about Φ20mm, and the wall thickness of stainless steel cladding tube is about 2mm.

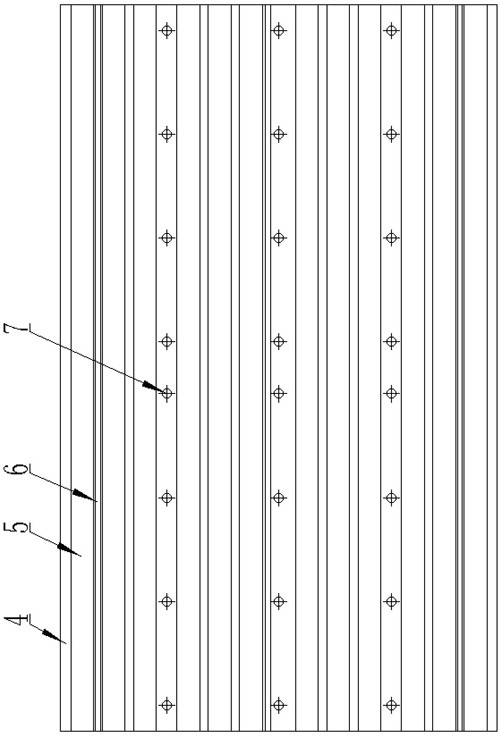

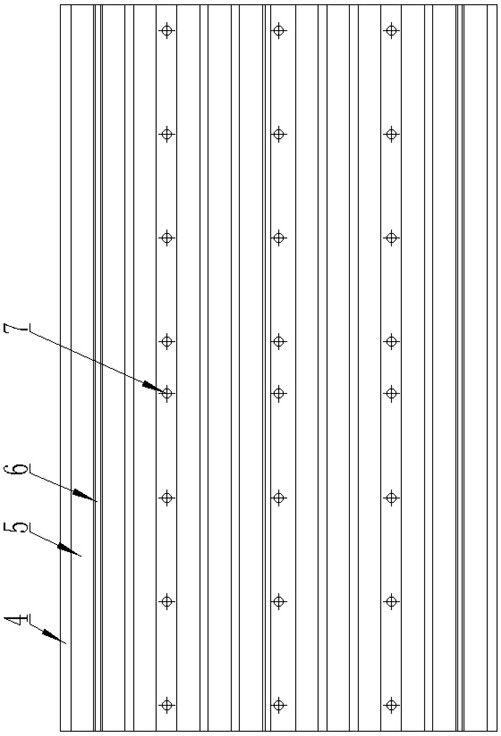

[0069] The electric heating element of this embodiment is used for Figure 5 , Figure 6 The regenerative heater shown is composed of an electric heating element, a regenerative element, a heat insulation layer, and a heater shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com