Vertical tube outer falling film evaporator

A technology of falling film evaporator and falling film evaporation, which is applied in vertical tube evaporators, evaporator accessories, evaporation, etc., can solve the problems of easy scaling and blockage of heat exchange tubes, and achieve scaling and blockage, increase The effect of improving the circulation area and evaporation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

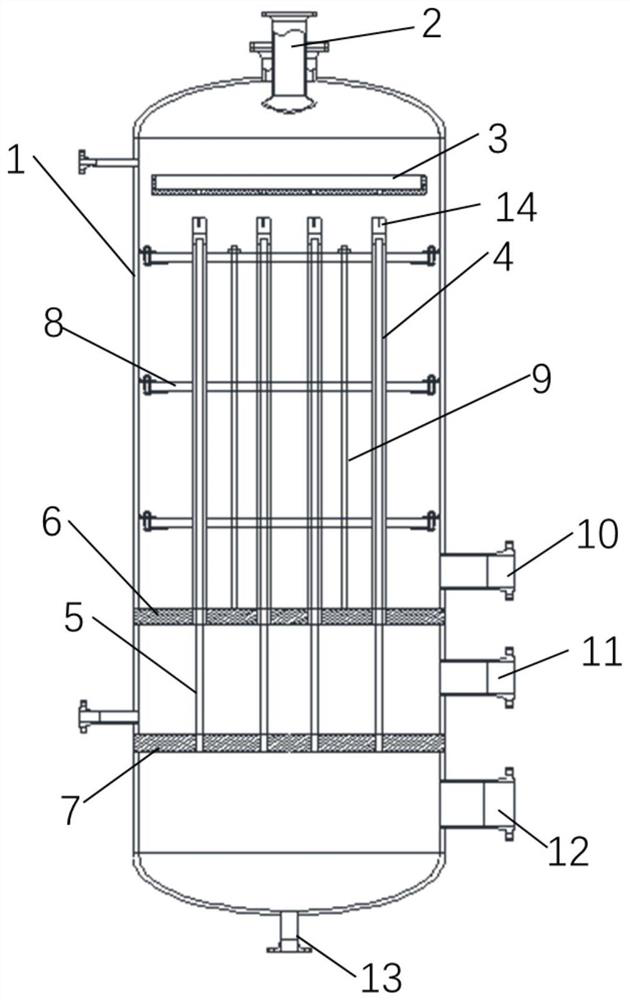

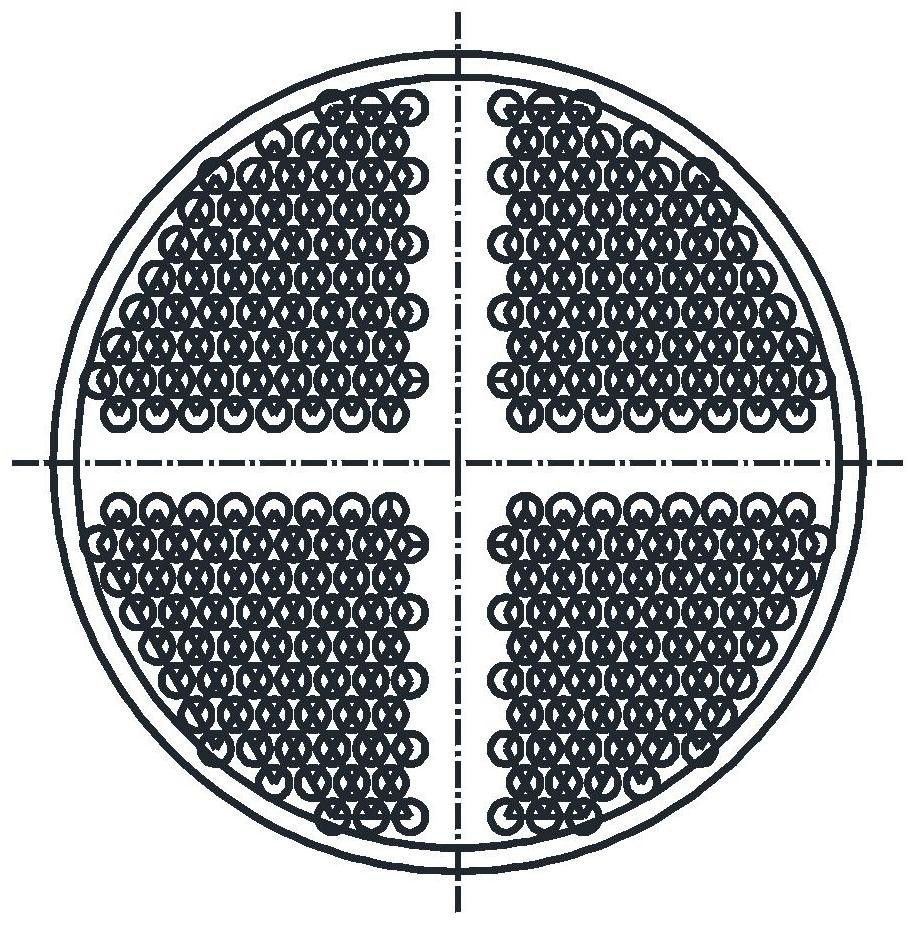

[0059] This embodiment provides a kind of figure 1 The vertical tubular filling film exhibitors include the outer casing 1; the top of the outer casing 1 is provided with a material inlet passage 2; a material is provided at the bottom of the outer casing 1. Outlet channel 13; the outer casing 1 is sequentially disposed in the direction of the material inlet passage 2, and the flying film evaporation unit includes a first tube plate 6, a second tube plate 7 and 336 single-headed heat pipe.

[0060] The end of the material inlet conduit 2 is provided with a spril-shaped liquid distributor.

[0061] The distribution disc 3 includes a cylindrical shape, including a bottom plate and a side wall of a falling lotion; the diameter of the drowning hole is 5 mm; the number of drops of the liquid hole is consistent with the number of single-headed heat transfer tubes 336. The height of the side wall is 200 mm.

[0062] The single-head heat transfer tube includes a guide tube 5 and a heat tr...

Embodiment 2

[0069] This embodiment provides a vertical tubular filling film evaporator, the difference between the outer filling film evaporator and Example 1 only in the diameter of the vertical tubular filming evaporator, and the rest Both the same as in Example 1.

Embodiment 3

[0071] This embodiment provides a vertical tubular filling film evaporator, the distal tubular membrane evaporator and the first embodiment of the first Example 1 only in that the gas passage is not provided between the heat exchange tubular bundles, and the remaining and embodiments are provided. 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com