PUR hot melt adhesive multifunctional reaction kettle with double-mixing stirring function and stirring method

A technology of mixing and stirring, hot melt adhesive, applied in mixers with rotary stirring devices, mixers, methods of chemically changing substances by using atmospheric pressure, etc. problem, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

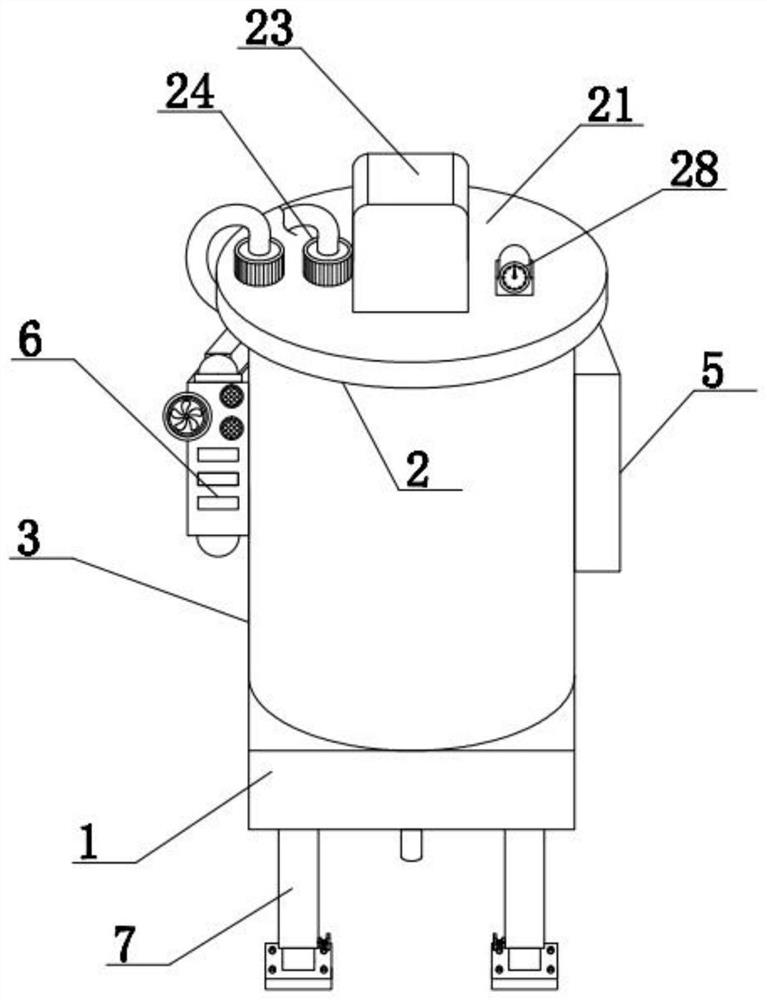

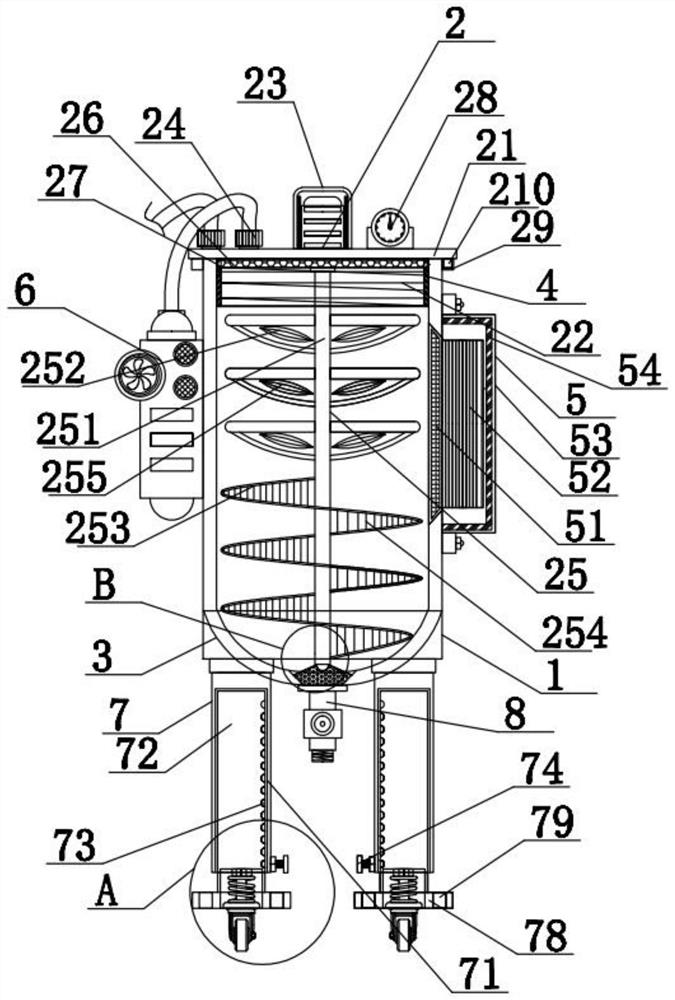

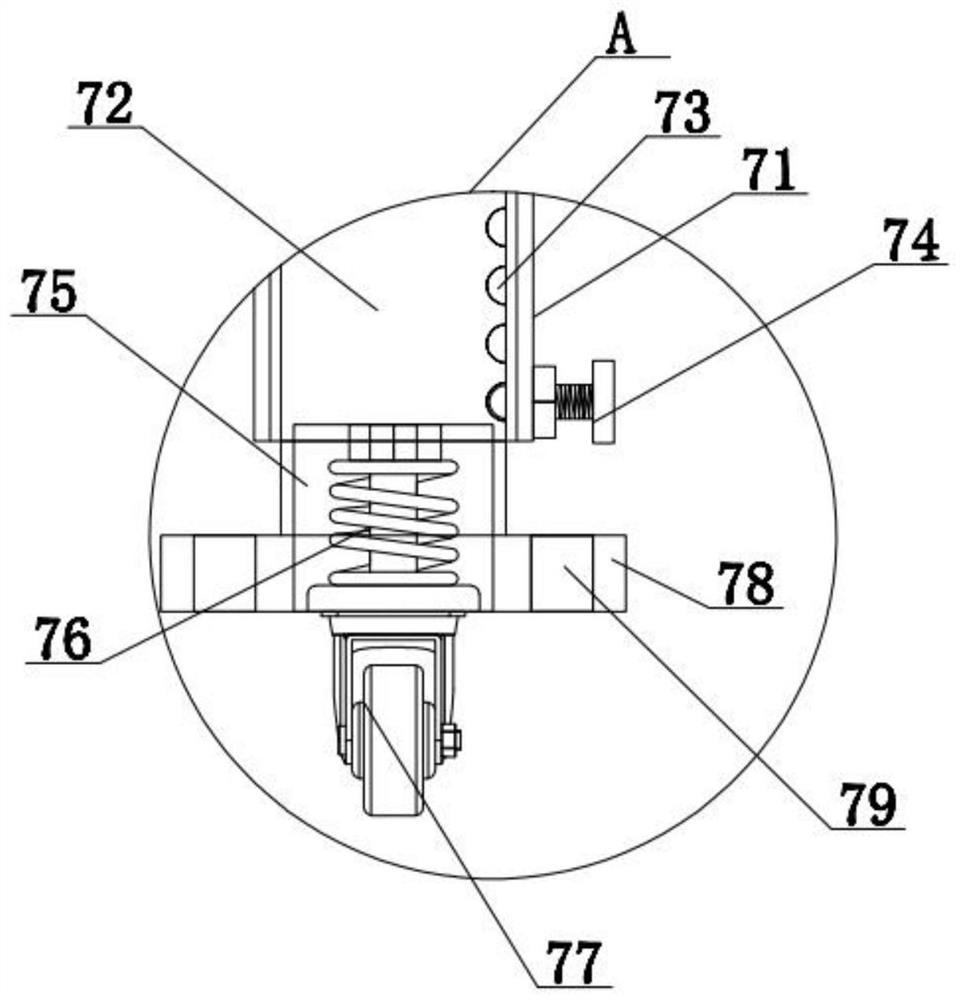

[0029] refer to Figure 1 to Figure 4 , a kind of PUR hot-melt adhesive multi-functional reaction kettle with double mixing and stirring function described in this embodiment includes a base 1, a reactor body 3 is fixedly installed on the top of the base 1, and an internal thread is provided on the inner side of the upper end of the reactor body 3 4. The top of the reactor body 3 is threadedly connected with the stirring mechanism 2 through the internal thread 4, the heating mechanism 5 is fixedly installed on the right side of the reactor body 3, and the vacuum pump 6 is fixedly installed on the left upper end of the reactor body 3, and the vacuum pump 6 passes through The ventilation pipe is connected with the stirring mechanism 2, the four corners of the bottom of the base 1 are fixedly installed with support legs 7, the bottom of the reactor body 3 is fixedly installed with a solenoid valve 8, and the upper end of the solenoid valve 8 communicates with the inner side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com