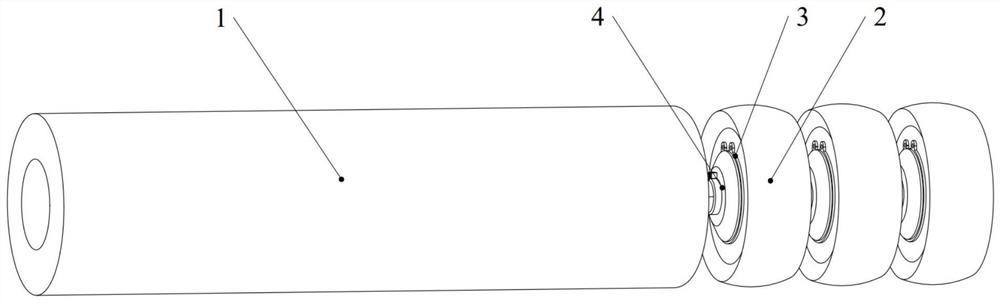

Distance-adjustable pipe bending core rod capable of being quickly disassembled and assembled and connecting device of distance-adjustable pipe bending core rod

A connecting device and spacing technology, which is applied in the field of adjustable-spacing pipe mandrels and connecting devices, can solve the problems of thinning the thickness of the curved convex sidewalls of pipe fittings, complicated installation and disassembly processes, and increased production costs, etc. The effect of development cost, adjustment time saving, and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

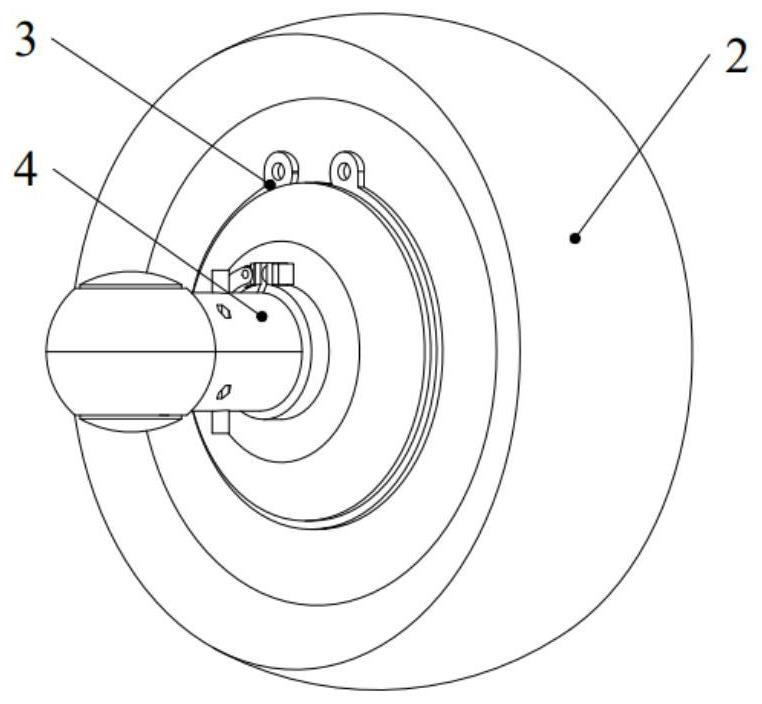

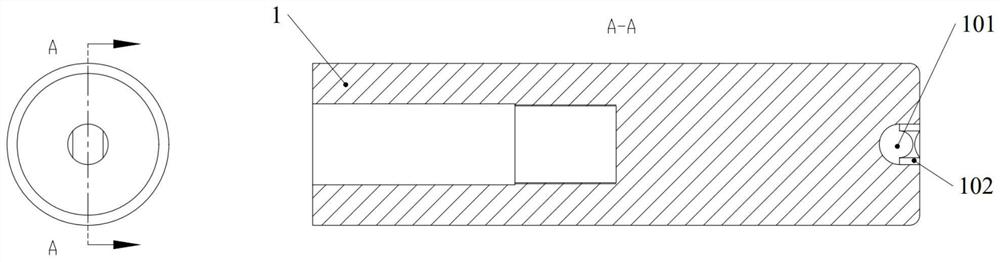

[0052] (1) Determine the core ball 2 and the mandrel 1 size according to the production requirements, and the core ball body 2 is mounted on the ball hinge 11 of the connecting device 4.

[0053] (2) Determine the core ball spacing according to the production requirements, turn the ball reamer head 5 so that the ball hinge head 5 ball center to the center of the ball hinge 11 ball center is equal to the target core ball spacing, turn the eccentric wheel clamping handle 14 The threaded hole of the ball hinge in the ball hinge is screwed to the ball hinge head 5.

[0054] (3) When the two adjustment slide 8 simultaneously moves inward by manual or tool, the transmission slider 6 overcomes the elastic force of the reset spring 7 to the left, the elastic force of the two-restricted spring 10 makes the two restricted blocks 9 close to the transmission slip The block 6 is contracted inwardly, until the limit block 9 completely retracts the limit step 502 of the ball hinge head 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com