Spherical NTO crystal and preparation method thereof

A technology of crystal and volume ratio, which is applied in the direction of organic chemical methods, offensive equipment, and a single substance as explosives. It can solve the problems of low charge density, poor molding performance of mixed explosives, and restrictions on the use of NTO.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of NTO crystal, comprises the following steps:

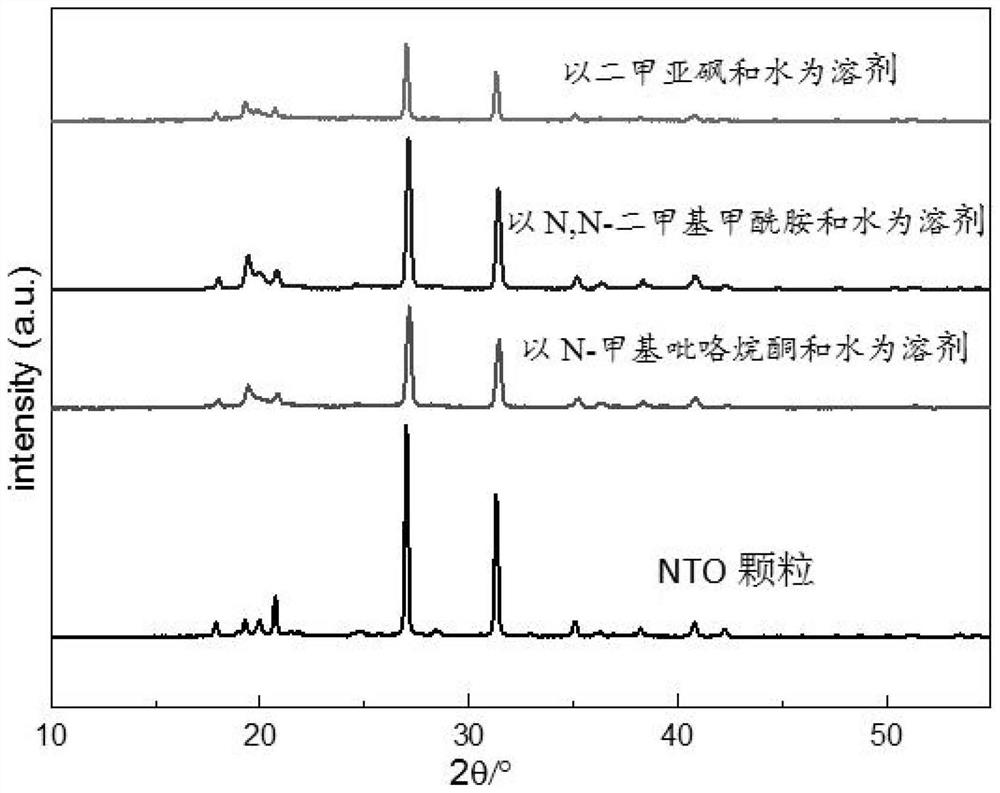

[0031] Dissolving NTO in a mixed solvent of dimethyl sulfoxide and water to obtain a saturated solution; the volume ratio of the dimethyl sulfoxide to water is 0.5-1.75:1, and the temperature of the saturated solution is 64-76°C ;

[0032] The saturated solution is cooled to crystallize, and the NTO crystals are precipitated; the cooling rate of the cooled crystallization is 3.0-4.5°C·min -1 ; The cooling crystallization is accompanied by stirring, and the stirring speed is 300-800r / min.

[0033] In the present invention, NTO is dissolved in a mixed solvent of dimethyl sulfoxide and water to obtain a saturated solution; the volume ratio of the dimethyl sulfoxide to water is 0.5 to 1.75:1, and the temperature of the saturated solution is 64 to 76°C. The present invention has no special limitation on the source of the NTO, and conventional commercially available...

Embodiment 1

[0047] The temperature of the double-layer jacketed reactor was adjusted to 70 ° C by means of external circulation temperature control; using the double-layer reactor as a container, 8 g of NTO was dissolved in 20 mL of a mixed solvent consisting of 12 mL of dimethyl sulfoxide and 8 mL of water. To obtain a saturated solution, keep warm for 30min;

[0048] Control the external circulation device of the reactor to make the reactor follow the temperature of 3.5°C·min -1 The cooling rate is lowered to 5°C; the cooling is accompanied by stirring at a speed of 500r / min; after cooling down to 5°C, continue to stir for 60 minutes;

[0049] The suspension obtained after stirring was subjected to suction filtration, washed with a saturated solution, and the filter residue obtained by suction filtration was freeze-dried at -84° C. for 240 min to obtain NTO crystals. The yield of the prepared NTO crystals was 80%.

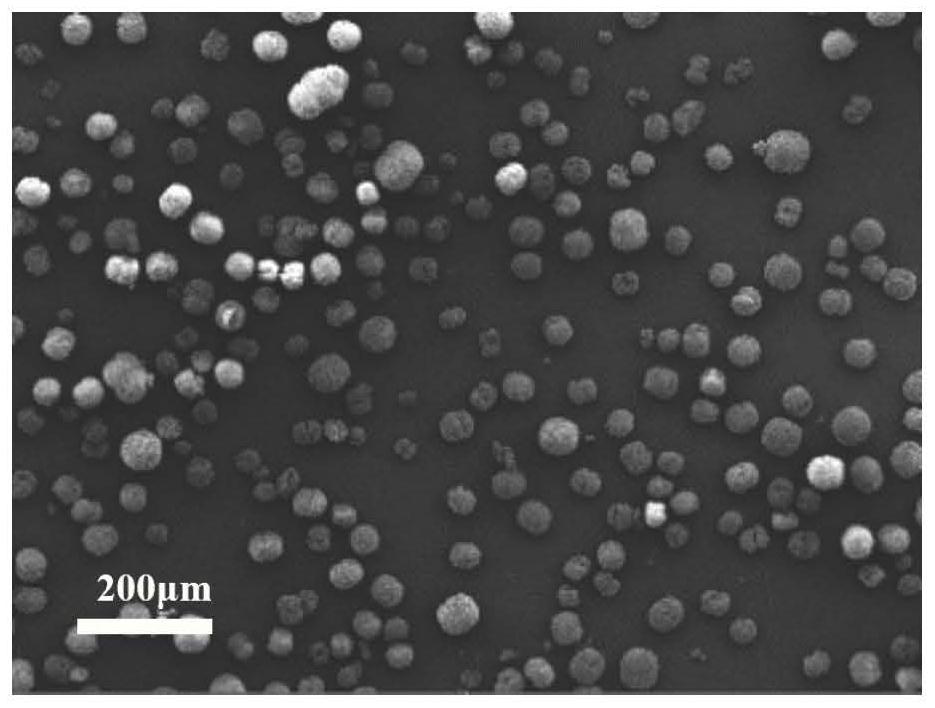

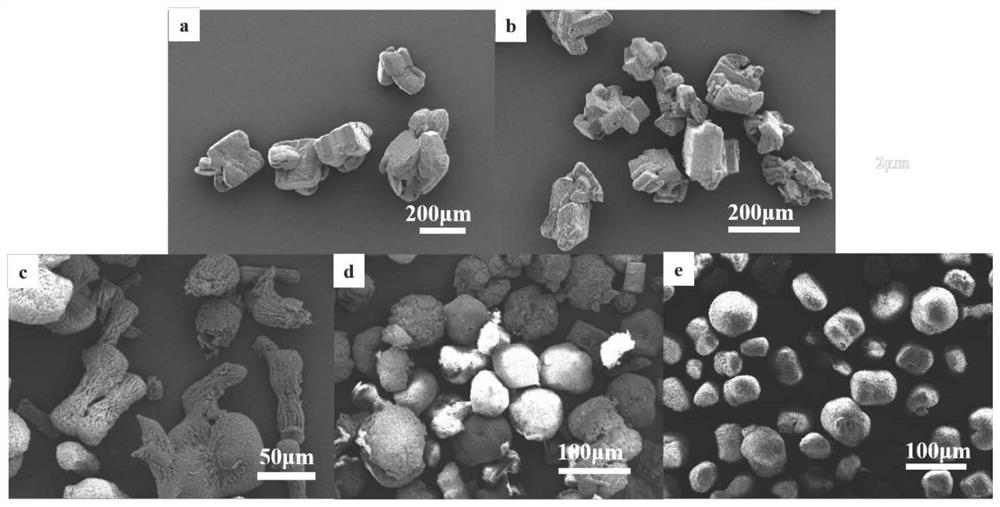

[0050] The NTO crystal prepared in Example 1 is subjected to scanning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com