Preparation method of 2-methyl-5-(1-methylpyrrolidine-2-yl) pyridine

A technology of methylpyrrolidine and alkenylpyrrolidone, which is applied in the field of preparation of 2-methyl-5-pyridine, can solve the problems of high cost, low output, potential danger to human health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

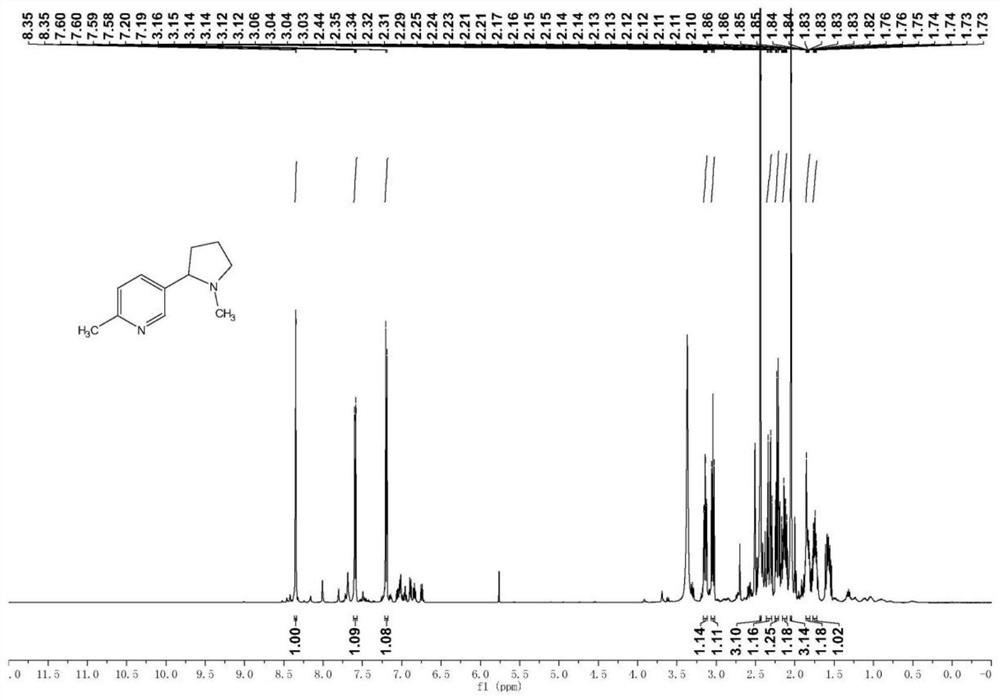

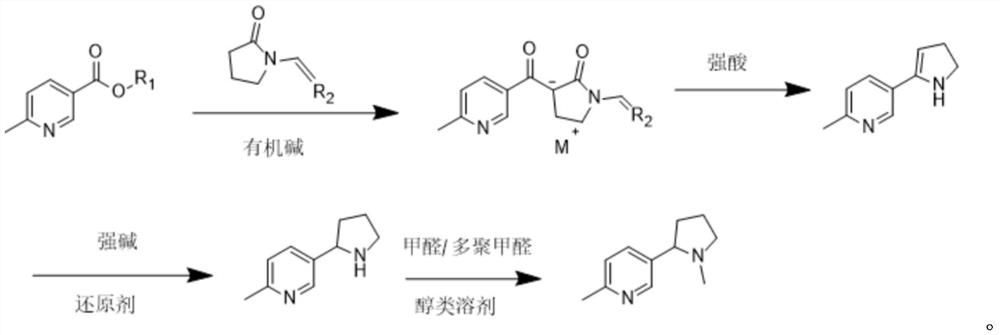

[0031] (1) Take 400g of methyl 6-methylnicotinate, 300g of vinylpyrrolidone, and 255g of sodium tert-butoxide. Under the protection of nitrogen, add 2L of toluene and mix well, then heat to 110°C and reflux. The product is precipitated in solid form and passed through LC -MS monitors the completion of the reaction. After 8 hours of reaction, the toluene solvent is filtered, washed three times with 300g of petroleum ether, and dried at 30°C for 2 hours to obtain 1-methyl-3-(6-methyl-nicotinoyl)-2- Vinylpyrrolidone salt 583g.

[0032] (2) 583g of 1-methyl-3-(6-methyl-nicotinoyl)-2-vinylpyrrolidone salt was obtained in step (1), added 1.25kg of 36% concentrated hydrochloric acid, heated to 88°C, and passed LC-MS Monitor the completion of the reaction and react for 44h.

[0033] (3) Cool down to -20°C, add 40% potassium hydroxide aqueous solution to adjust the pH to 11, add 570g of sodium dithionite solid, stir and react at 75°C, monitor the completion of the reaction by LC-MS, a...

Embodiment 2

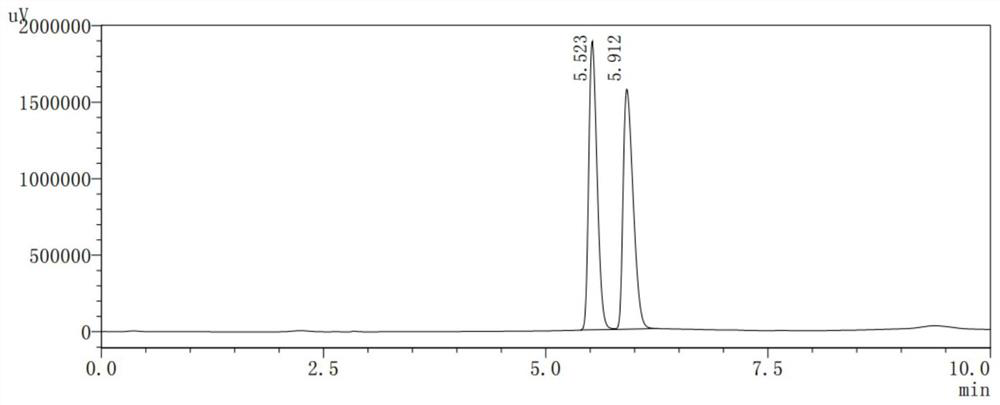

[0041] Other conditions and operations were the same as in Example 1, except that the reducing agent in step 3 was 343g lithium triethylborohydride, and step 3 obtained 263g of 2-methyl-5-(pyrrolidin-2-yl)pyridine. Finally, 235 g of pure 2-methyl-5-(1-methylpyrrolidin-2-yl)pyridine was obtained, with a GC purity of 99.2%. Based on 6-methylnicotinic acid methyl ester, the total yield was 50.00%.

Embodiment 3

[0043] Other conditions and operation are identical with embodiment 1, and difference is that reducing agent is 443g sodium dithionite and 77g lithium triethylborohydride in step 3, and step 3 obtains 2-methyl-5-(pyrrolidin-2-yl)pyridine 307g. Finally, 276 g of pure 2-methyl-5-(1-methylpyrrolidin-2-yl)pyridine was obtained, with a GC purity of 99.3%. Based on 6-methylnicotinic acid methyl ester, the total yield was 58.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com