Reticulated artistic terrace and preparation method thereof

An artistic and textured technology, applied in the field of textured art floor and its preparation, can solve the problems of high process requirements, cumbersome construction steps, hard and unnatural textured effect, etc., and achieve the effect of simple method and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

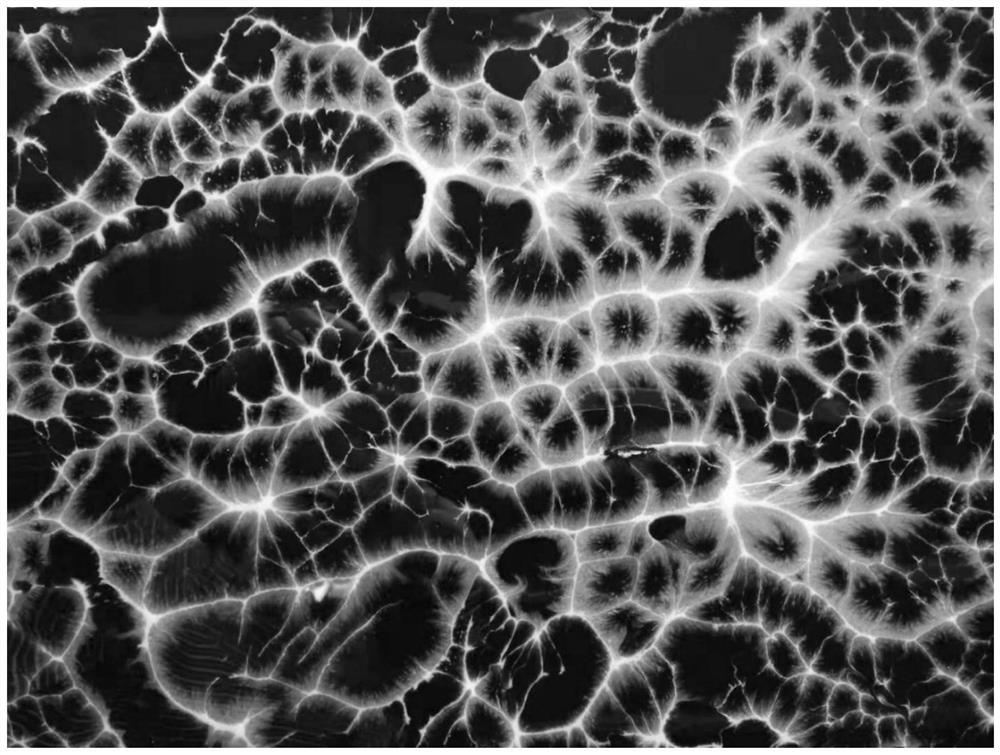

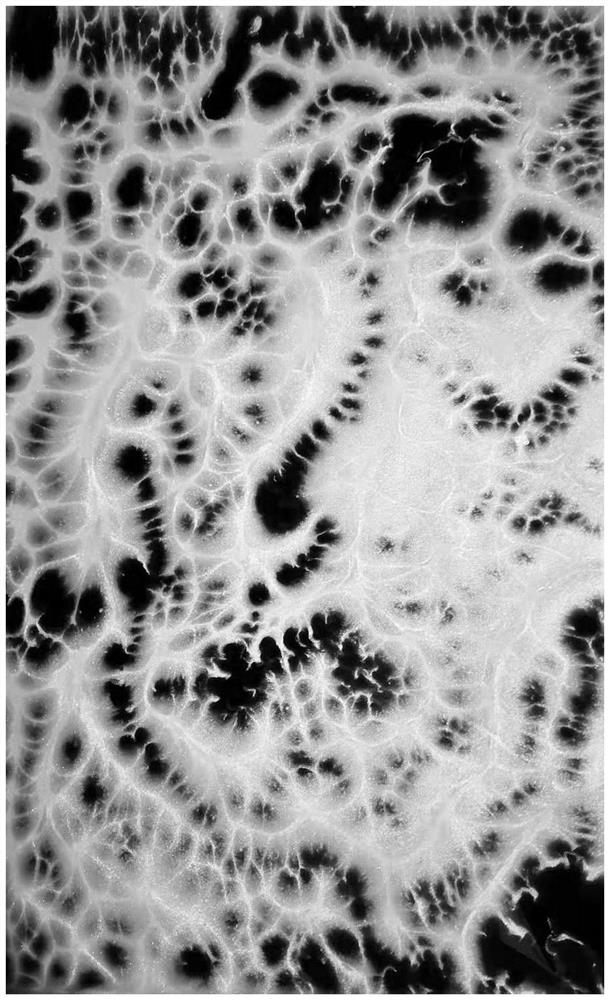

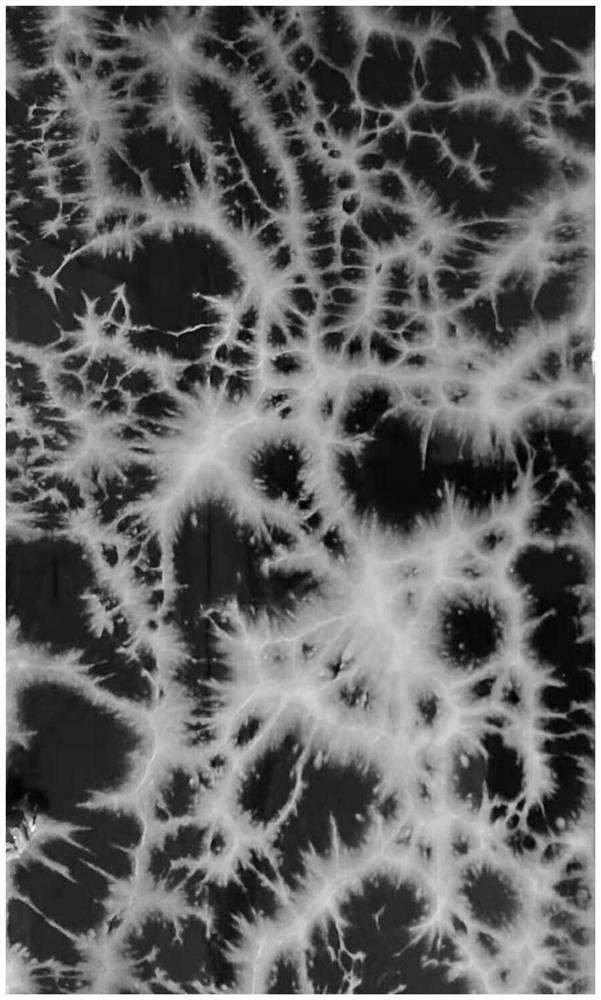

[0026] The preparation method of the reticulated art floor of the present invention comprises the following steps: spreading the primer on the substrate, covering the modeling varnish on the primer within 5-25 minutes by sprinkling dots, and after curing, the reticulated pattern is obtained. Art floor.

[0027] As can be seen from the above description, the beneficial effect of the present invention is that: the modeling paint in the raw material of the reticulated art floor provided by the present invention has a hammer pattern agent, so that the modeling paint generates a vortex under the action of the modeling paint, and the center of the vortex is concave downward and Diffusion and extrusion around, the extrusion process mainly acts on the pearlescent powder in the primer, so that the pearlescent powder is concentrated and dispersed on the edge of the modeling paint under the extrusion of the modeling paint. At the same time, due to the specific thickener in the primer, it ...

Embodiment 1

[0046] Reticulated art floor, prepared from primer and modeling paint;

[0047] The primer is composed of the following components in parts by weight:

[0048] 0901 Epoxy resin dispersion (Wanhua Chemical) 884kg, Dipropylene glycol butyl ether 50kg, SURFYNOL 104E wetting agent 3kg, RHODOLINE DF691 defoamer 1kg, U905 thickener (Wanhua Chemical Vesmody TMU905) 30kg, KC8100B pearl powder (Fujian Kuncai Material Technology Co., Ltd.) 100kg, yellow color paste (Baichuan Chemical CP4) 0.05kg and 332 curing agent (Wanhua Chemical) 500kg;

[0049] The modeling paint is composed of the following components in parts by weight:

[0050] 0901 Epoxy resin dispersion 844kg, dipropylene glycol butyl ether 130kg, SURFYNOL 104E wetting agent 5kg, defoamer 1kg, SN-9006 hammer pattern agent (Shenzhu Chemical) 20kg, black color paste (Baichuan Chemical CP1) 0.2kg and 332 curing agent curing agent 500kg.

[0051]The preparation method of the above-mentioned reticulated art floor compris...

Embodiment 2

[0053] Reticulated art floor, prepared from primer and modeling paint;

[0054] The primer is composed of the following components in parts by weight:

[0055] 0901 epoxy resin dispersion 850kg, dipropylene glycol butyl ether 40kg, SURFYNOL 104E wetting agent 2kg, RHODOLINE DF691 defoamer 0.5kg, U905 thickener 20kg, KC8100B pearl powder 80kg, green color paste (Baichuan Chemical CP6) 0.04 kg and 332 curing agent 480kg;

[0056] The modeling paint is composed of the following components in parts by weight:

[0057] 0901 epoxy resin dispersion 800kg, dipropylene glycol butyl ether 120kg, SURFYNOL 104E wetting agent 4kg, RHODOLINE DF691 defoamer 0.5kg, SN-9006 hammer pattern agent (Shenzhu Chemical) 15kg, black color paste (Baichuan Chemical CP1 )0.2kg and 332 curing agent curing agent 450kg.

[0058] The preparation method of the above-mentioned reticulated art floor comprises the following steps: spreading the primer on the substrate, covering the modeling paint on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com