Self-operated safety shut-off valve with pneumatic reset axial flow structure

A safety cut-off valve, self-operated technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of laborious reset, long time to balance pressure, high pressure, etc., and achieve good sealing, fast and stable shut-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

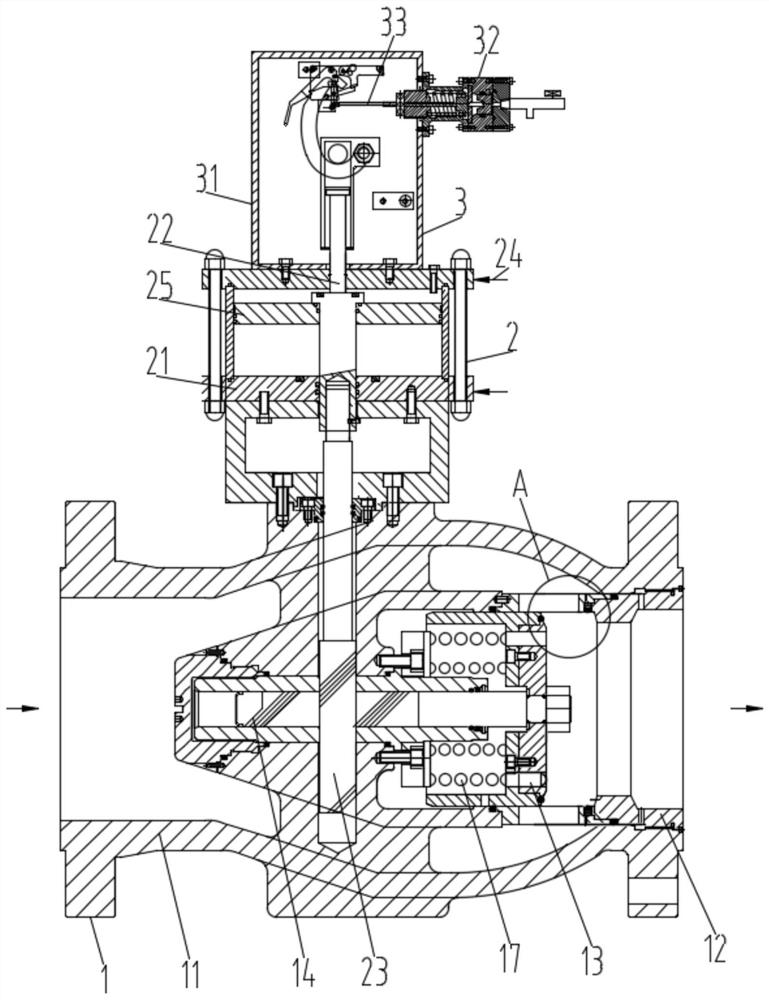

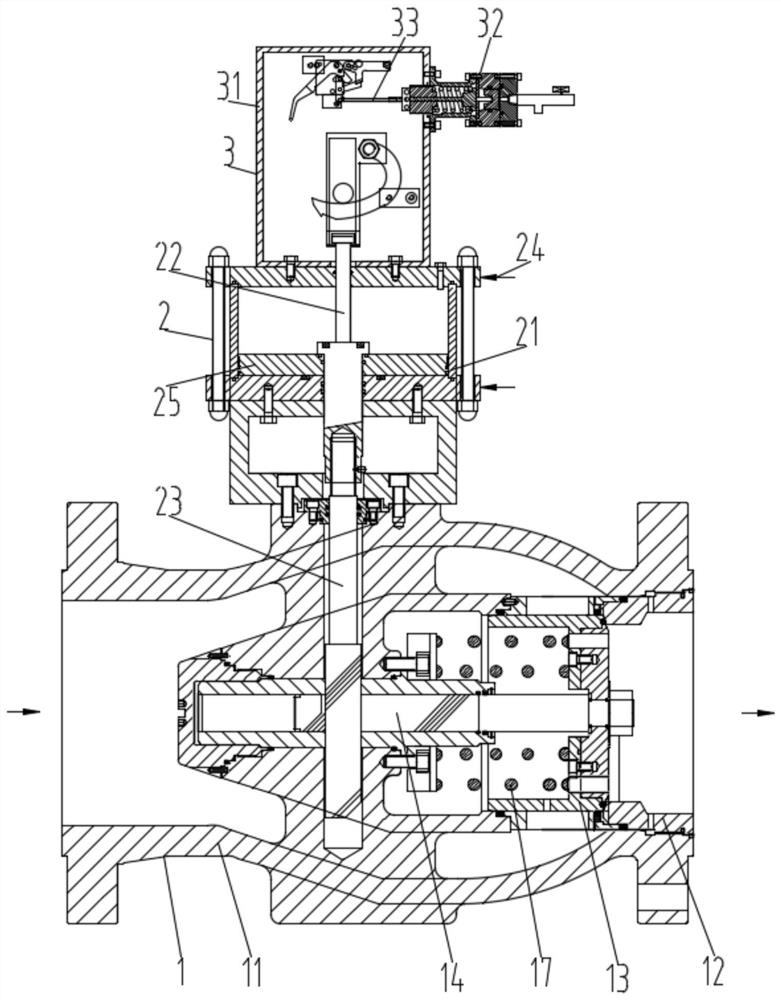

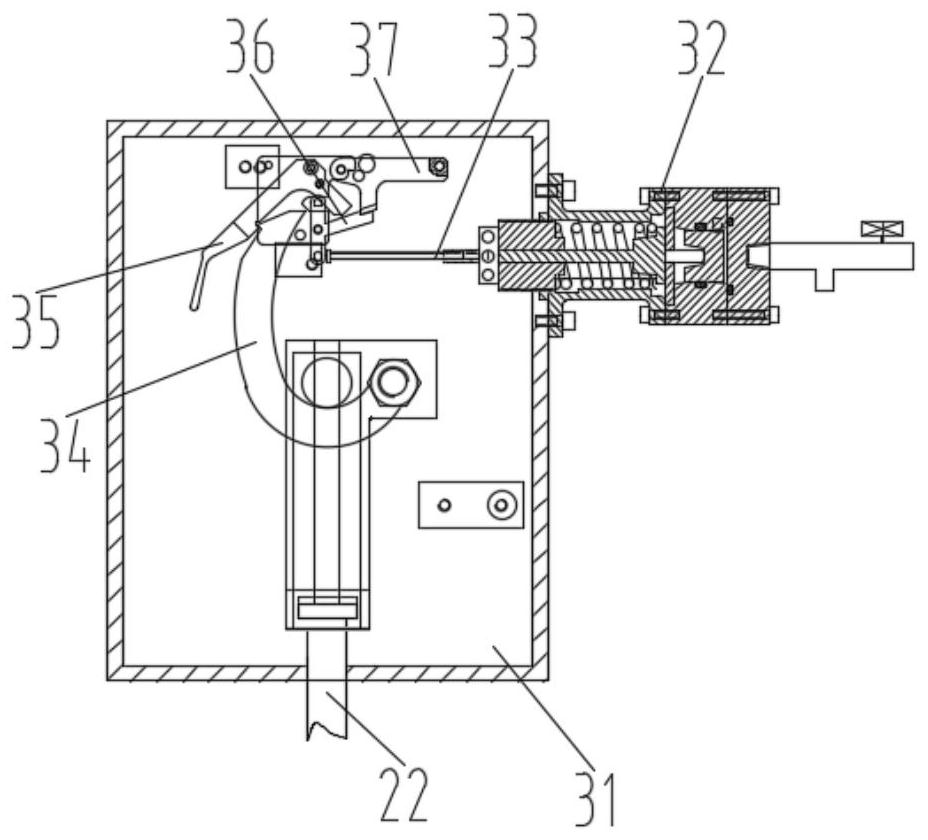

[0027] Please see attached figure 1 To attach Figure 5 , the embodiment of the present invention proposes a self-operated safety shut-off valve with an axial flow structure and pneumatic reset, including a valve main body 1; The mechanism 2 is connected with a self-operated controller 3 for controlling the automatic closing of the valve main body 1 .

[0028] The valve main body 1 includes a pure axial flow valve body 11, a stop sleeve 12 is installed at the outlet end of the inner wall of the pure axial flow valve body 11, and a stop sleeve 12 is installed in the pure axial flow valve body 11 to be movable with the stopper. The sleeve 12 matches the spool assembly 13, and the end of the stop sleeve 12 close to the spool assembly 13 is in contact with the sleeve 18, and the stop sleeve 12 is threaded into the pure axial flow valve body 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com