Fuse safety test method for simulating vertical free drop by hammering

A test method and safety technology, applied in the field of fuzes, can solve the problems of unreliable methods, few samples, and products with potential safety hazards such as falling and misjudgment as qualified, so as to achieve the effect of eliminating potential safety hazards and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

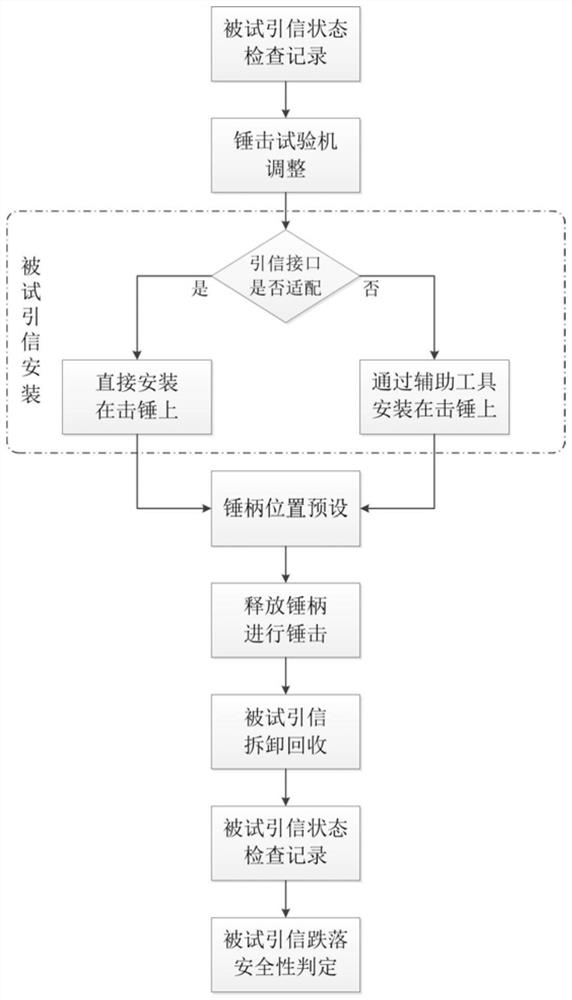

[0048] combine figure 1 , a kind of fuze safety test method of simulating vertical free fall with hammering according to the present invention, concrete steps are as follows:

[0049] Step 1. Before the test, check and record the status of the tested fuze 1 according to the requirements of method 104 of GJB 573B-2020 "Test Methods for Fuze and Fuze Parts Environment and Performance".

[0050] Step 2. Hammer testing machine adjustment:

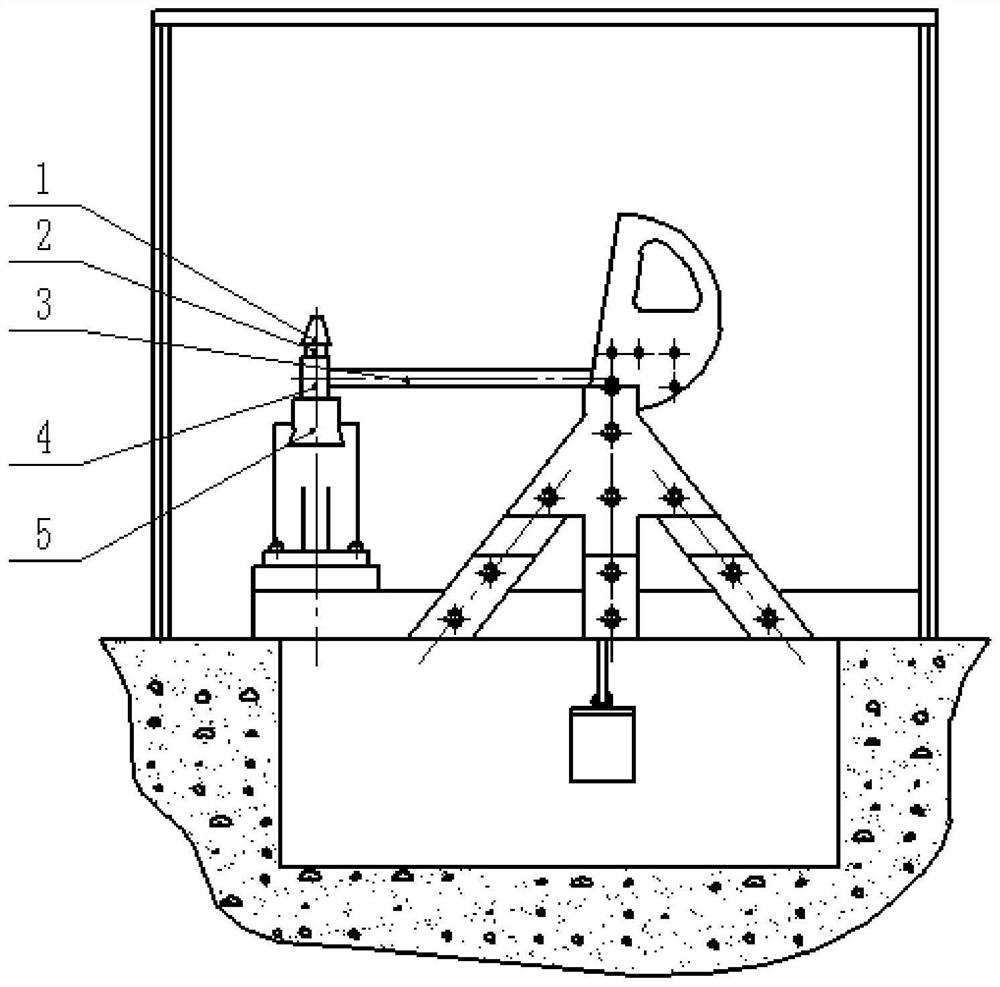

[0051] According to the drop impact situation to be simulated, judge whether the standard hammer test machine can realize the simulation of the drop impact overload. If the simulation can be realized, use the standard hammer test machine for testing; if not, you can add buffer materials of different materials and thicknesses on the standard anvil, change the material and heat treatment state of the anvil (5) or change the hammer (4) Material and heat treatment status (sorted according to the degree of difficulty), adjust the impact overload p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap