Corrosion rate measuring device and method based on slide rheostat

A sliding rheostat, corrosion rate technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of low experimental efficiency, discrete data, heavy workload, etc., and achieve the goal of improving convenience and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

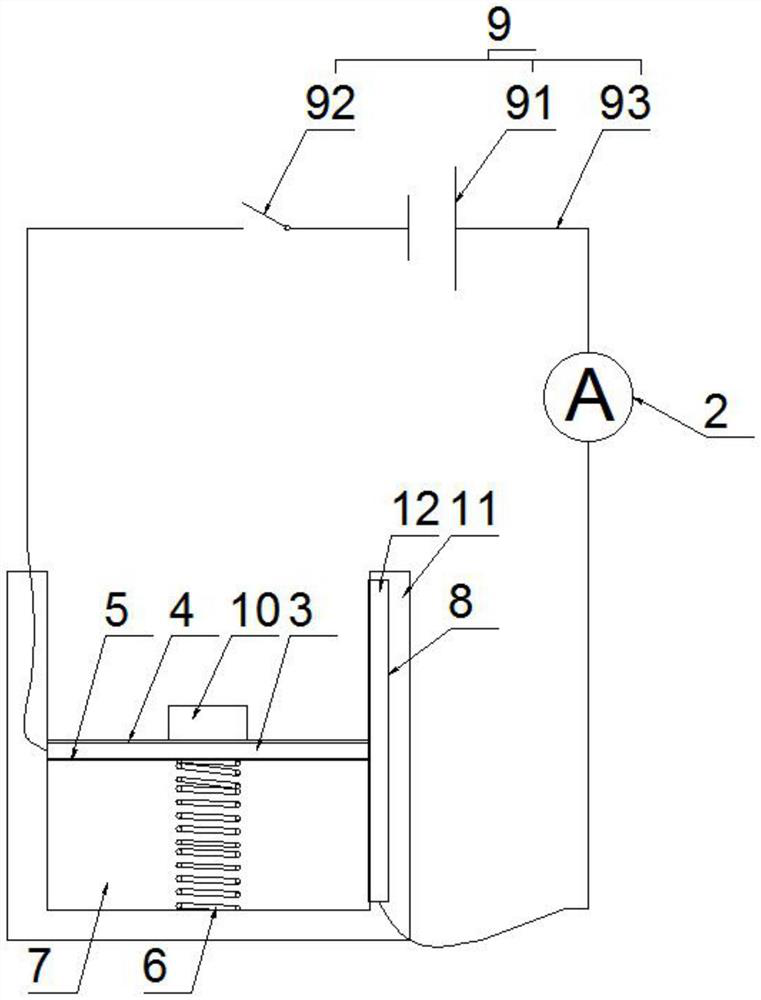

[0036] Such as figure 1 , 2As shown, it is a preferred embodiment of the corrosion rate measuring device based on the sliding rheostat of the present invention, the measuring device includes a sliding rheostat 1 and a current measuring device 2, and the sliding rheostat 1 includes an insulating casing 11 and a resistor 12 , the resistor 12 is vertically arranged on the insulating casing 11, the resistor 12 is slidingly fitted with a metal plate 3 that is electrically connected vertically, and the top and bottom of the metal plate 3 are respectively provided with a first insulating layer 4 and a second insulating layer 5. A vertical spring 6 is provided at the bottom of the second insulating layer 5 , and a series circuit 9 is provided between the current measuring device 2 , the resistor 12 and the metal plate 3 .

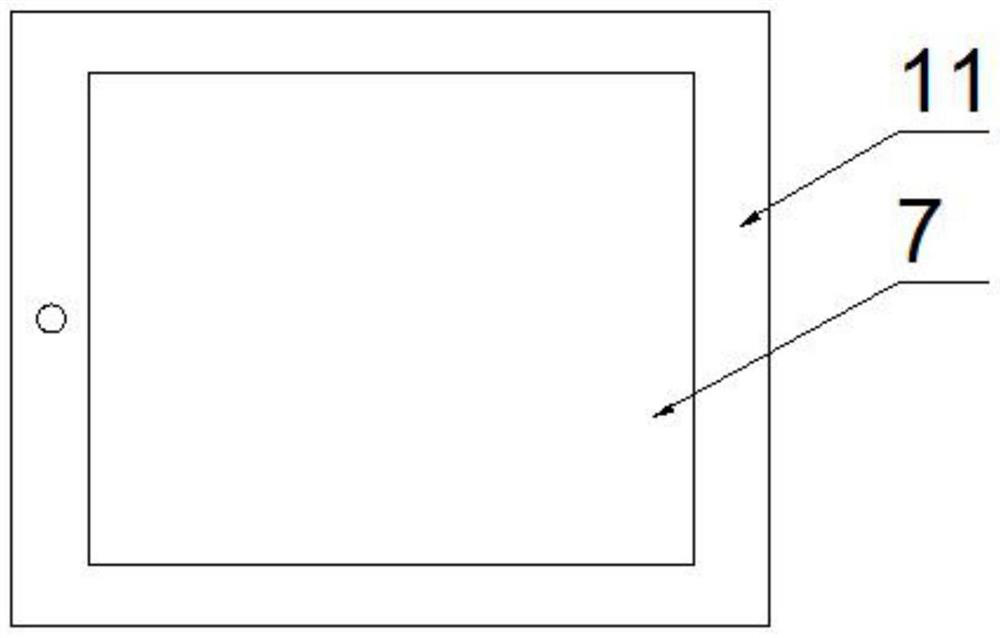

[0037] In the above-mentioned corrosion rate measuring device, preferably, the insulating casing 11 is provided with a first groove 7, the metal plate 3 and the s...

Embodiment 2

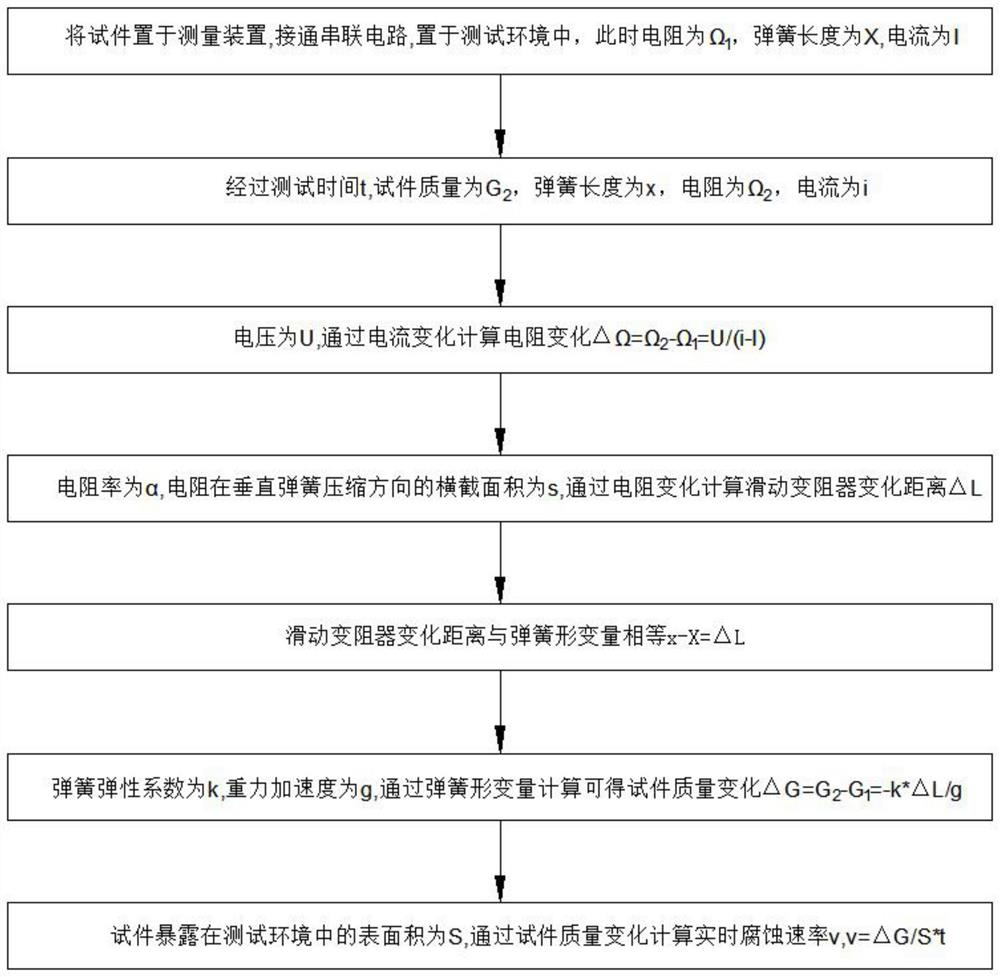

[0047] A preferred embodiment of the sliding rheostat-based corrosion rate measurement method of the present invention, the measurement method is: using the measurement device described in the embodiment, placing the test piece on the top of the first insulating layer 4, and connecting the series circuit 9 Afterwards, according to the current data of the current measuring device 2, the test time, the voltage of the series circuit 9, the resistance value of the resistor 12, the resistivity of the resistor 12, the original mass of the test piece, the cross-sectional area of the resistor 12 in the compression direction of the vertical spring 6, and the spring 6 The real-time corrosion rate is calculated from the modulus of elasticity, the acceleration of gravity, and the surface area of the specimen exposed to the test environment.

[0048] Such as image 3 Shown, above-mentioned corrosion rate measurement method, preferably, its specific steps are:

[0049] 1 Test the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com