Flow accelerated corrosion experiment test analysis method and system

A flow-accelerated corrosion and testing system technology, applied in the direction of analyzing materials, material analysis by electromagnetic means, measuring devices, etc., can solve the problems such as the failure to completely eliminate the FAC phenomenon of the water supply and drainage system and the blockage of the downstream elbow, and achieve the elimination of the FAC phenomenon. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

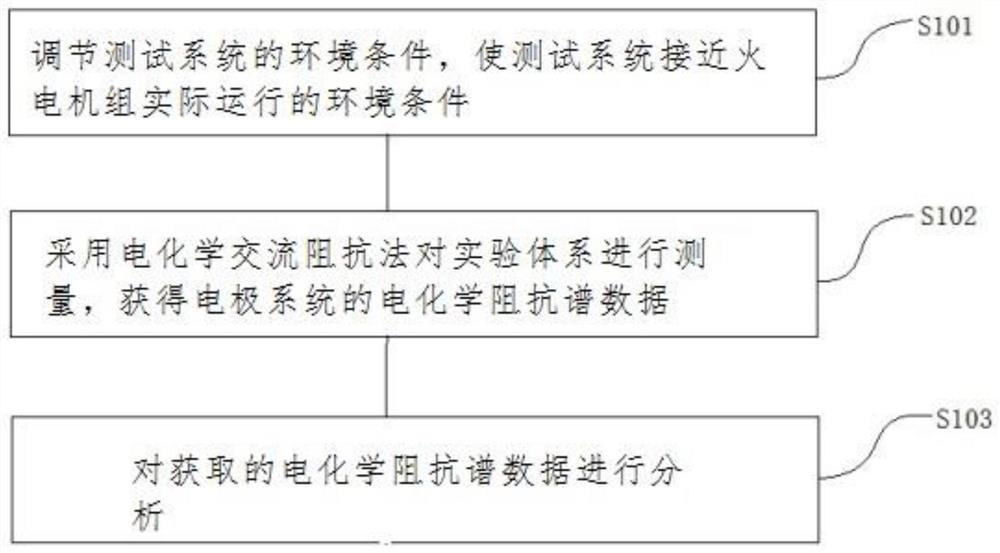

[0037] The present application provides a flow acceleration corrosion experiment test analysis method, including: as follows:

[0038] S101, adjust the environmental conditions of the test system, enabling the test system to approach the actual environmental conditions of the thermal power set;

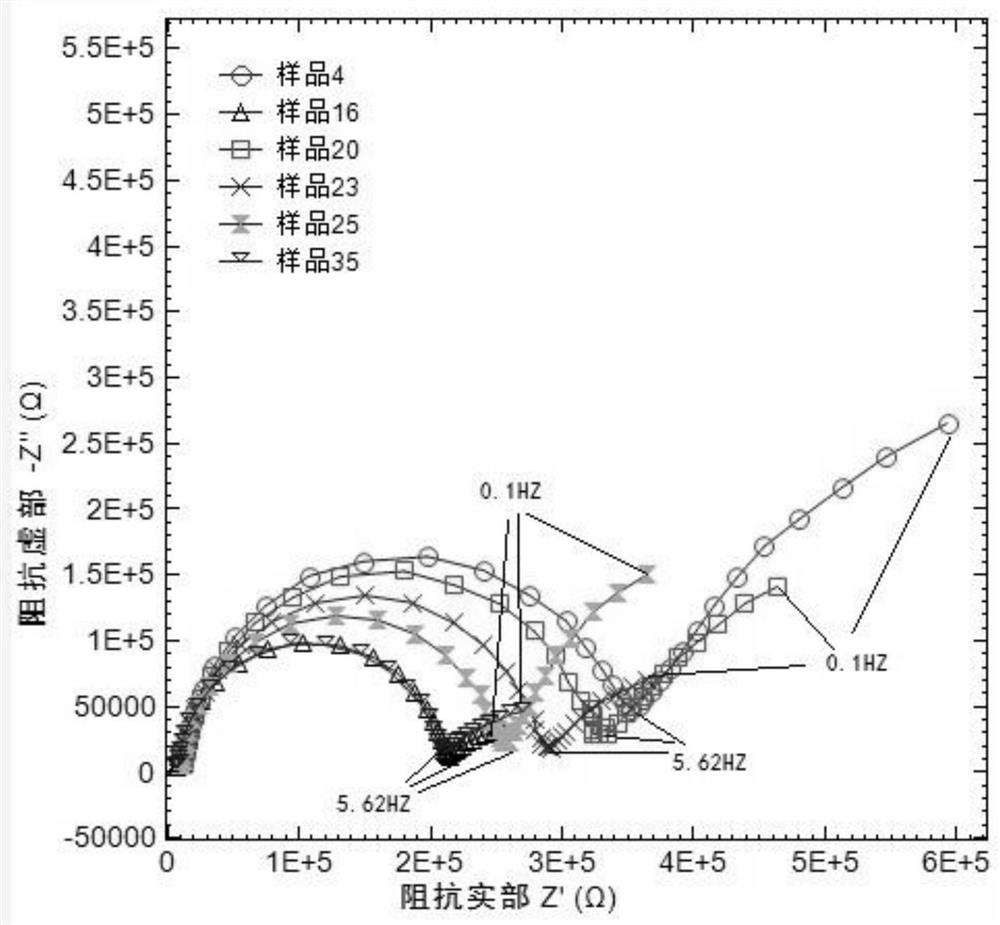

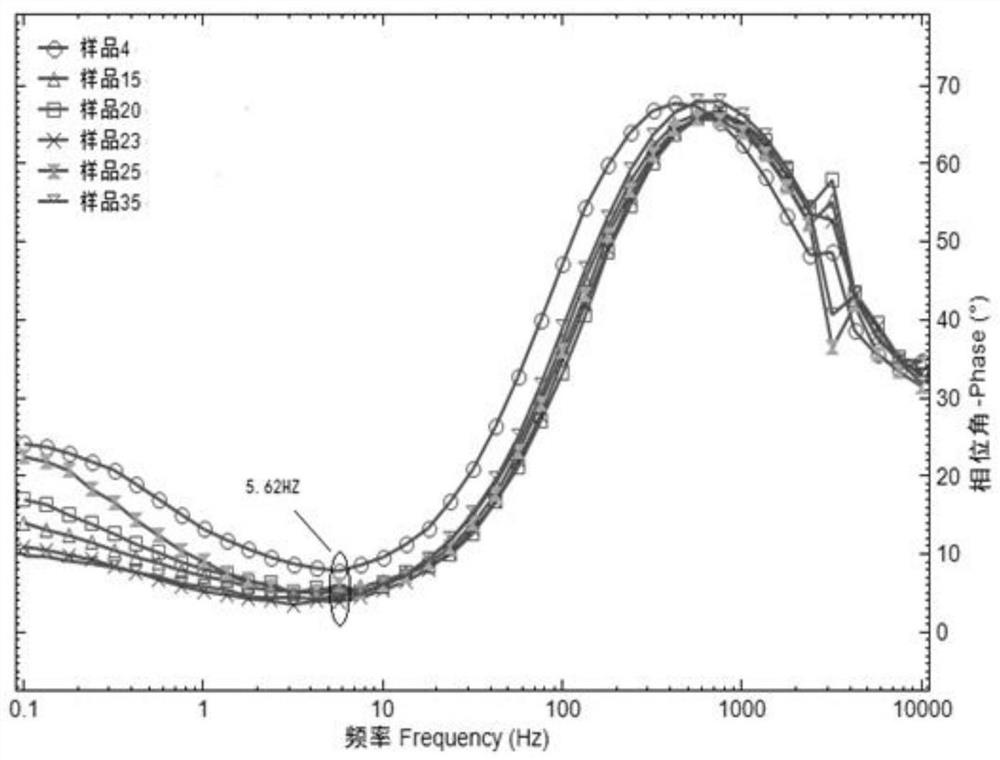

[0039] S102, using electrochemical AC impedance method to measure the experimental system, and obtain electrochemical impedance spectrum data of electrode system;

[0040] S103 analyzes the acquired electrochemical impedance spectrum data.

[0041] The electrochemical AC impedance method monitors corrosion along the circumference direction in the circumferential direction by an electrochemical AC impedance method, which can truly study the cause of 90 ° eluting in the fire generator sets.

[0042] This method will be described in detail below with reference to the drawings:

[0043] Such as figure 1 As shown, S101, adjustment of the environmental conditions of the test system, enabling th...

Embodiment 2

[0057] The second embodiment of the present application provides a flow acceleration corrosion experiment test system, including: water tank, parameter control module, centrifugal pump and electrochemical AC impedance test system module, and each module constitutes a closed loop circuit.

[0058] The parameter control module mainly includes a temperature control module, a pressure control module, a pH control module, a flow control module, and a medium-containing oxygen content control module, which is close to the actual operating environment of the thermofor unit through the synergistic effects between each module. The temperature control module includes a PID controller, a thermocouple, and a heating resistor wire. The temperature control module is mainly adjusted in the test system, and the temperature range is from 20 to 30 ° C in the present embodiment, and the preferred temperature is 25 ° C. . The pressure control module is mainly controlled by the medium liquid level pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com