Intelligent positioning method and device for impact load

A technology of intelligent positioning and impact load, applied in the field of detection, to achieve the effect of improving solution speed and precision, improving accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

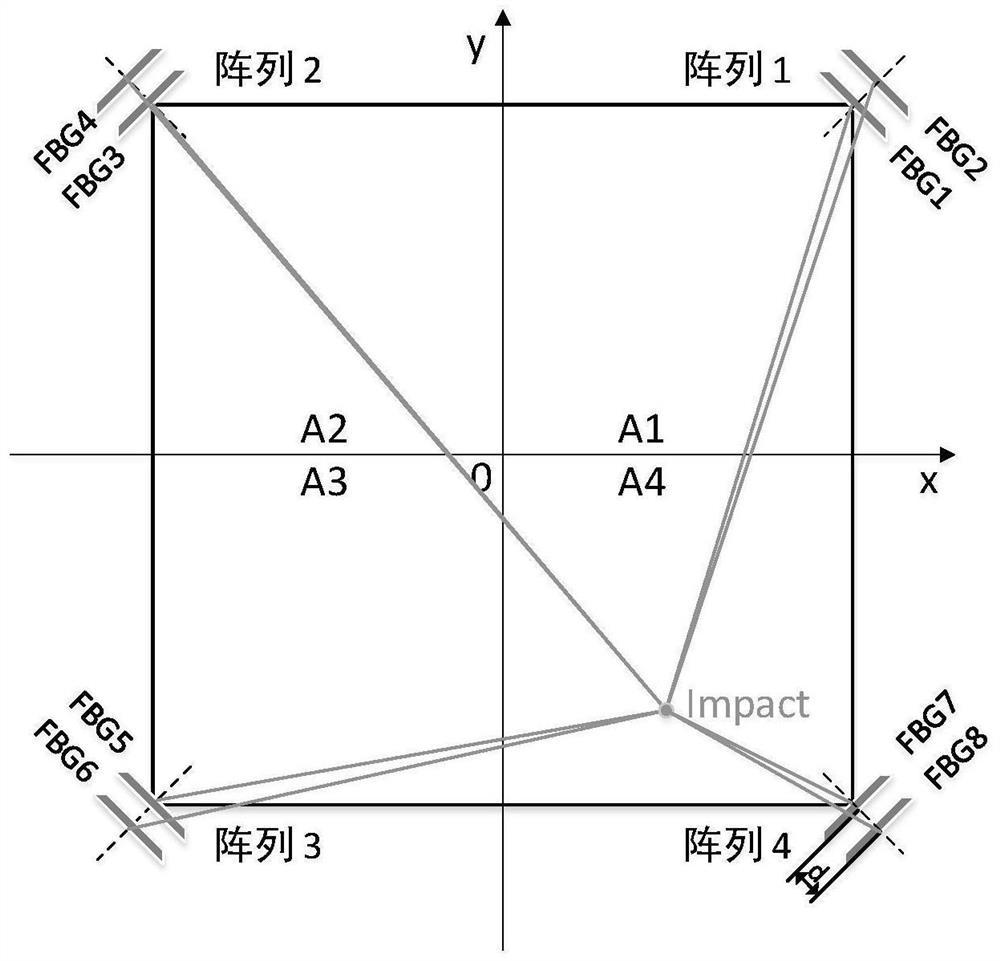

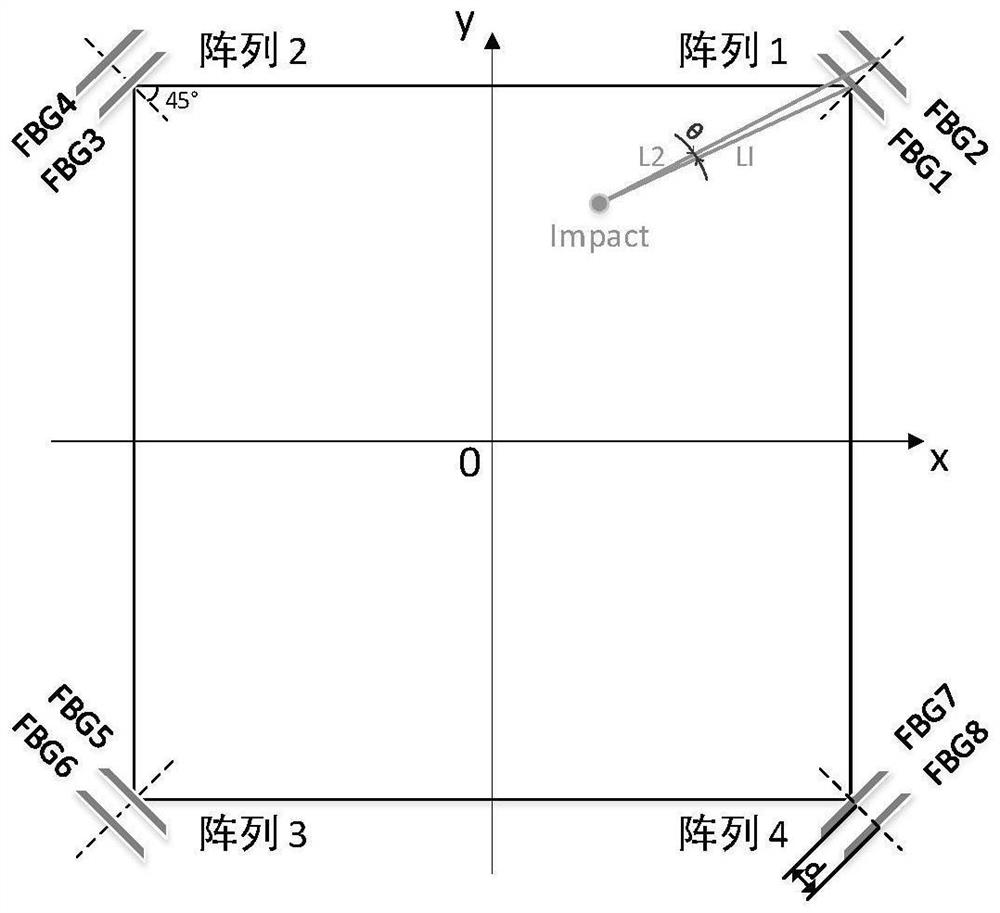

[0033] Such as figure 1 , 2 As shown, an impact load intelligent positioning device includes a sensor array provided in four directions around the impact zone, the present embodiment, the impact of the composite plate, and each direction sensor array includes a relative impact area. Two sensors arranged in the center of radiation, four sensor arrays are located in the same plane. The sensor is the fiber Bragg grating sensor (FBG), and the four sensors arrays are located at four corners of the square, and the fiber Bragg grating sensor is axially opposite the square of the square in the corner point vertically. The angle between the impact is greater than or equal to 45 ° in the stress propagation direction of the composite plate, and the high frequency components in the amplitude frequency characteristics are small.

[0034] The sensor array is J, J = 1, 2, 3, 4; the sensor is FBG I, I = 1, 2, 3, 4, 5, 6, 7, 8. Two FBGs in each set of sensor arrays D.

[0035] Attach the right ang...

Embodiment 2

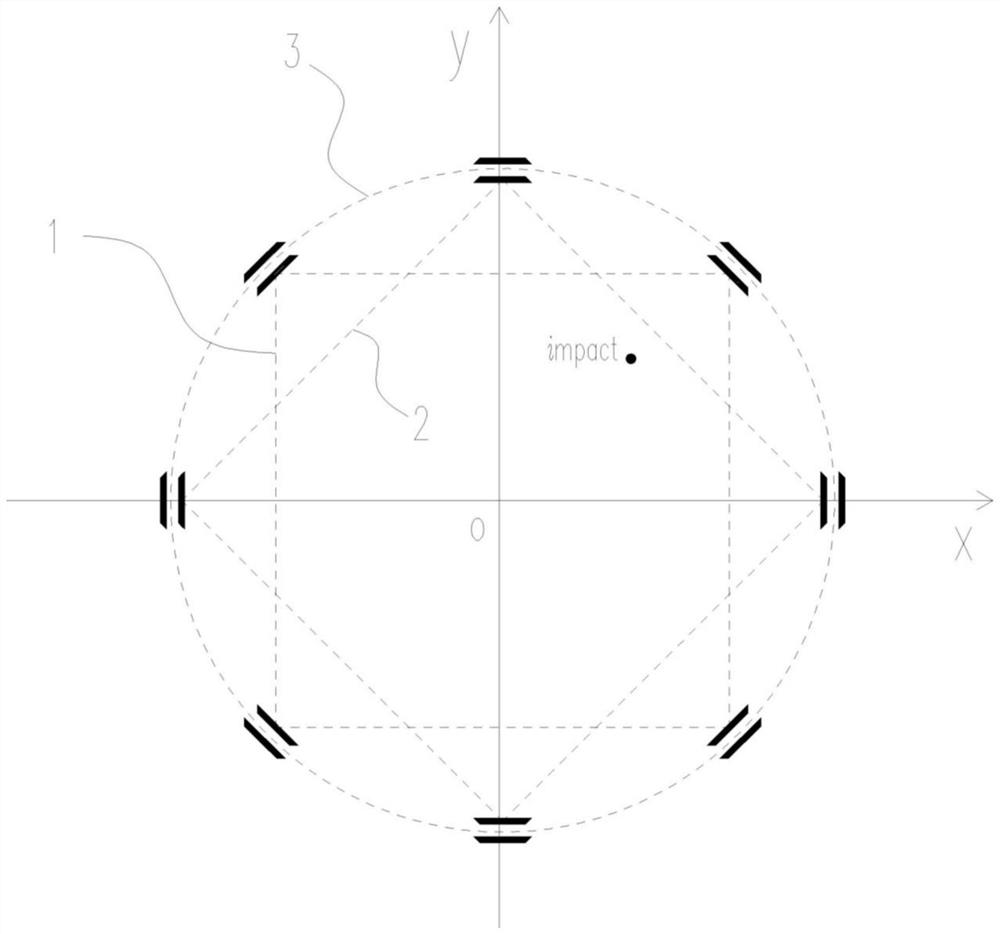

[0103] Such as image 3 As shown, the above-described embodiment is that the four sensor arrays on the square angle point are one detecting unit, and the sensor arrays of the two detecting units are located on the same circumference 3, and the sensor arrays of the two detecting units are arranged at each other. All sensor array spacing, that is, the first detecting unit on the first square 1, and the second detecting unit is on the second square 2.

[0104] The positioning method is that the average value of the position coordinates obtained by the two detecting units serves as the final position coordinate, and since the two detecting units are symmetrical in position, the detection can be achieved. For example, when the impact point is located close to the central portion of a square, it corresponds to the position of the other square, and the structural measurement error of the two has complementarity, whereby the average value of the detection result of the two detection units ...

Embodiment 3

[0108] Such as Figure 4 As shown, in relation to the above-described embodiment, the two detection units located on the same circumference are one detection group, and a plurality of detection groups are provided around the impact zone, and the circumference of the detection group is different, all the circumference of all detection groups. Concentric, the sensor array between different detection groups is equal in circumferential angular intervals, that is, the sensor on different circumferences is not corresponding to the radial direction.

[0109] The average of the position coordinates determined by the multi-group detection group as the final position coordinate. Further, depending on the size of the impact force, the detection value of the different detection group is selected as the final positioning value, for example, when the impact force is large, the detection value of the detection unit on the large circumference is employed. When the impact force is small, the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com