Angle adjusting device and self-danger-avoiding type sun-tracking solar power generation equipment

An angle adjustment device and an angle adjustment technology, applied in the field of solar power generation, can solve the problems of solar panel blowing, damage or even scrapping, high production cost, poor linkage adjustment accuracy and stability, etc., to improve solar power generation power, production and assembly. Low cost and smooth angle adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

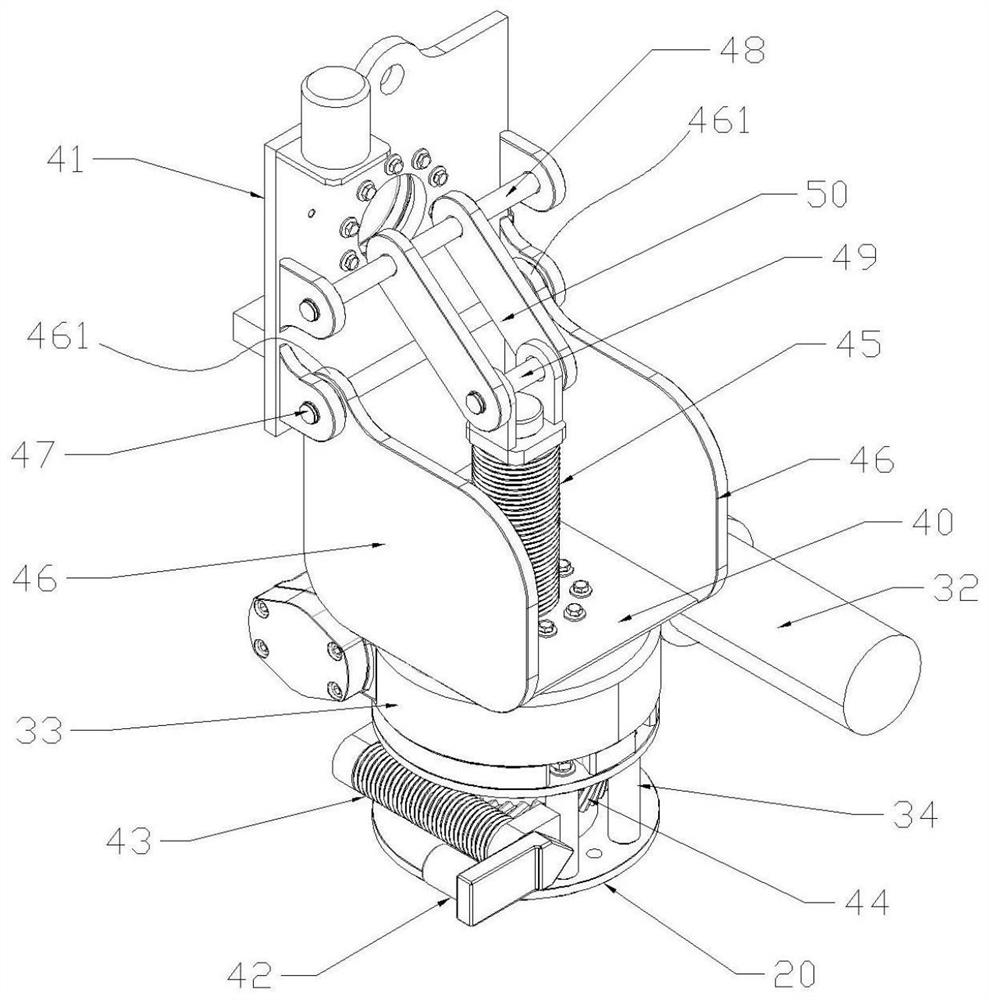

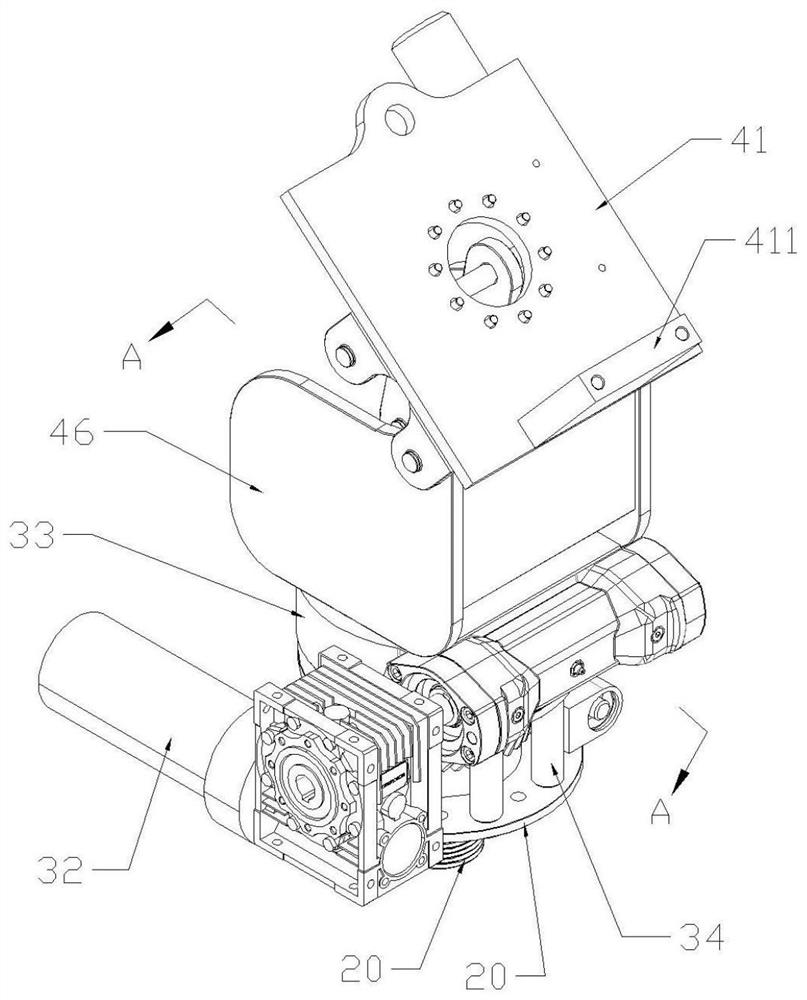

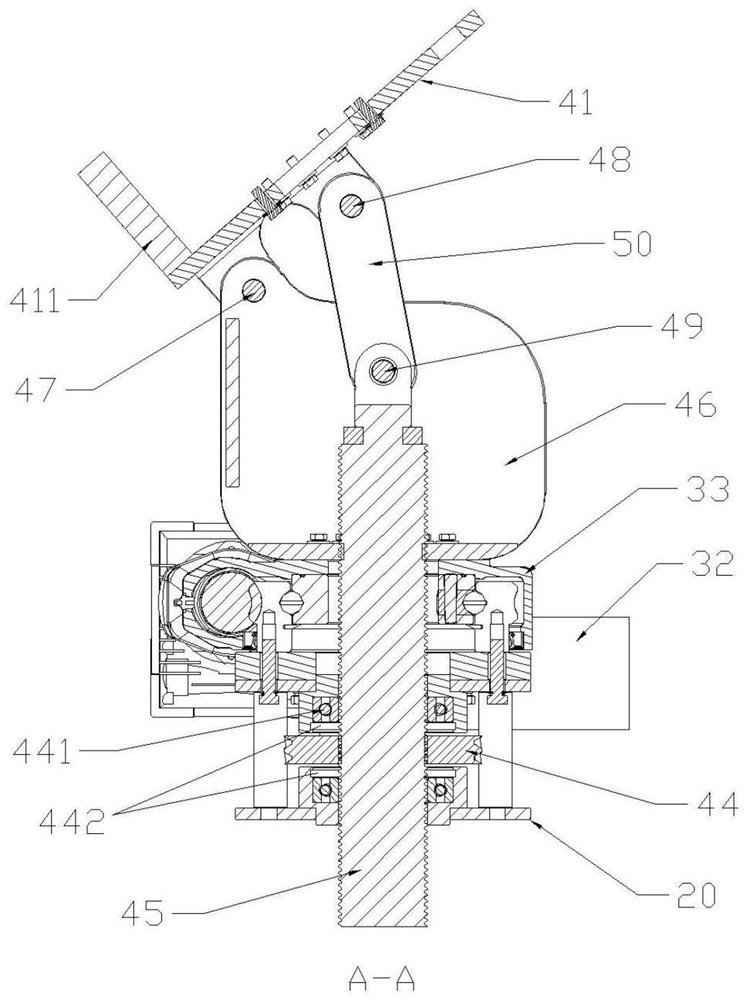

[0045] Such as Figure 1-4 As shown, the angle adjustment device of the present invention includes a base 20, a horizontal angle adjustment assembly, and a pitch angle adjustment assembly. The base 20 is provided with a number of support columns 34, and the horizontal angle adjustment assembly includes a transmission-connected horizontal Motor 32, rotary reducer 33, the horizontal motor 32 is electrically connected with the external control system 21, the lower part of the rotary reducer 33 is fixedly installed on the support column 34, and the horizontal angle adjustment assembly is powered by the horizontal motor 32, which can be adjusted left and right. Turn to achieve angle adjustment in the horizontal direction;

[0046] The pitch angle adjustment assembly includes a fixed plate 40, a mounting plate 41, and a pitch motor 42, a short worm 43, a double-sided gear 44, and a long worm 45 that are sequentially connected by transmission. The pitch motor 42 is electrically conne...

Embodiment 2

[0050] Such as Figure 5-Figure 12 As shown, in this implementation, the self-avoiding sun-tracking solar power generation equipment includes a frame 1 and a blade retracting device. The bottom of the frame 1 is symmetrically provided with a number of mounting holes 11, and the device is installed through the mounting holes 11 by bolts. Install and fix at the finger position. The installation of the equipment does not require cumbersome construction preparations. It is only necessary to pre-embed the bolts at the installation position in advance, then hoist the solar power generation equipment to the bolt position, align the installation holes 11, and then tighten the nuts to complete the installation. And fixed, the equipment can be put into use. According to the geology of different installation sites, installation methods include but are not limited to expansion bolts, pre-embedded cement foundations, screw piles, etc. A control system 21, an inverter 22 electrically conne...

Embodiment 3

[0059] Such as Figure 10 , Figure 11 As shown, in this embodiment, at least one cleaning brush 621 is provided on the back of the bracket 62, and the cleaning brush 621 on the back of the bracket 62 at the front end is in contact with the surface of the solar photovoltaic panel 64 at the rear end. , in order to achieve a better cleaning effect in practical applications, preferably two cleaning brushes 621 are provided. At each sunrise and sunset time node control system 21 of the power generation equipment will control the blade retracting device to expand and retract the solar blade 6. During each expansion and retraction process, the solar blade 6 will perform relative movement, and at the same time the support The cleaning brush 621 on the back of the 62 will clean the panel 63 and the solar photovoltaic panel 64 of the solar blade 6 . At the same time, the panel 63 adopts easy-to-clean glass to improve cleaning efficiency.

[0060] Such as Figure 15 As shown, in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com