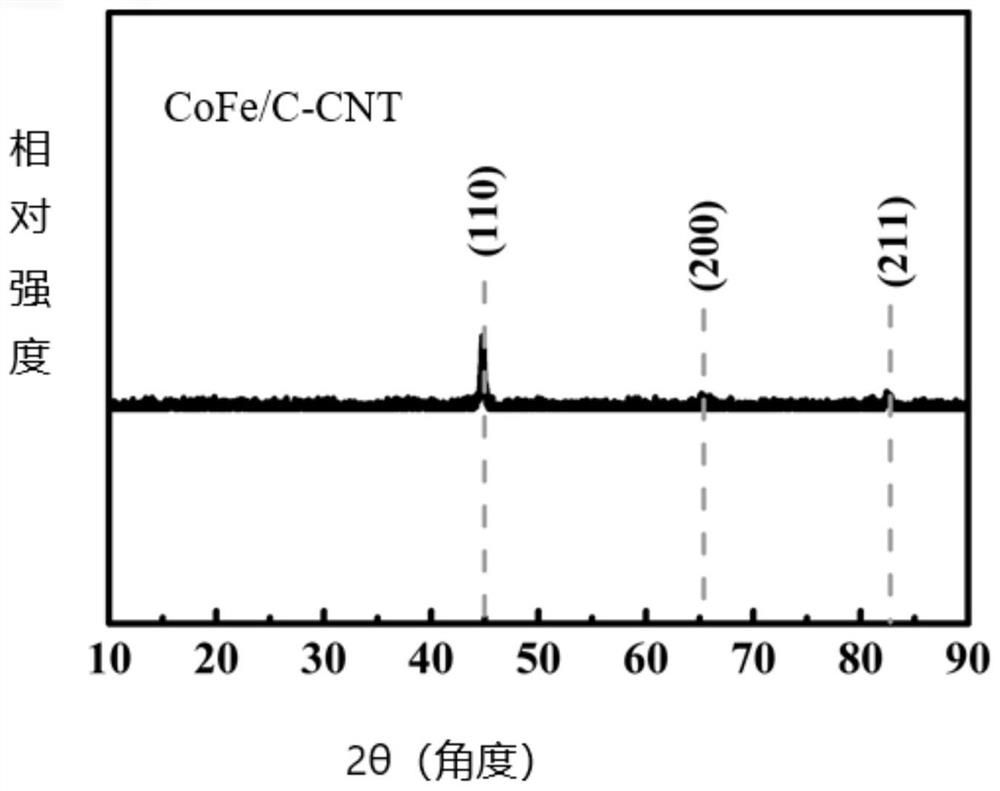

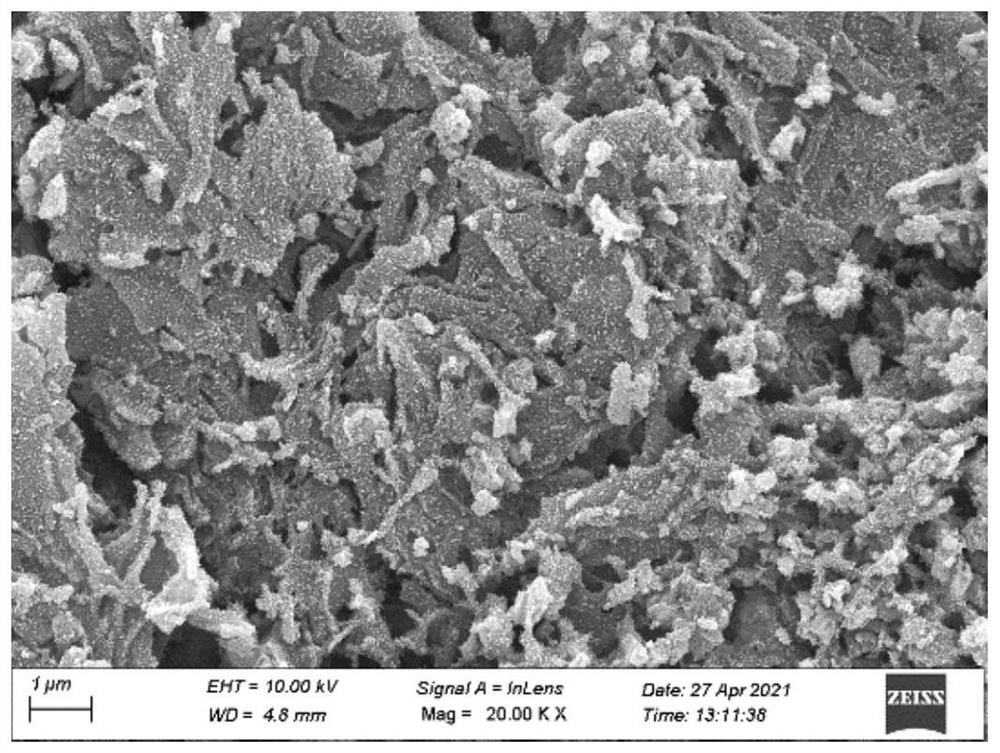

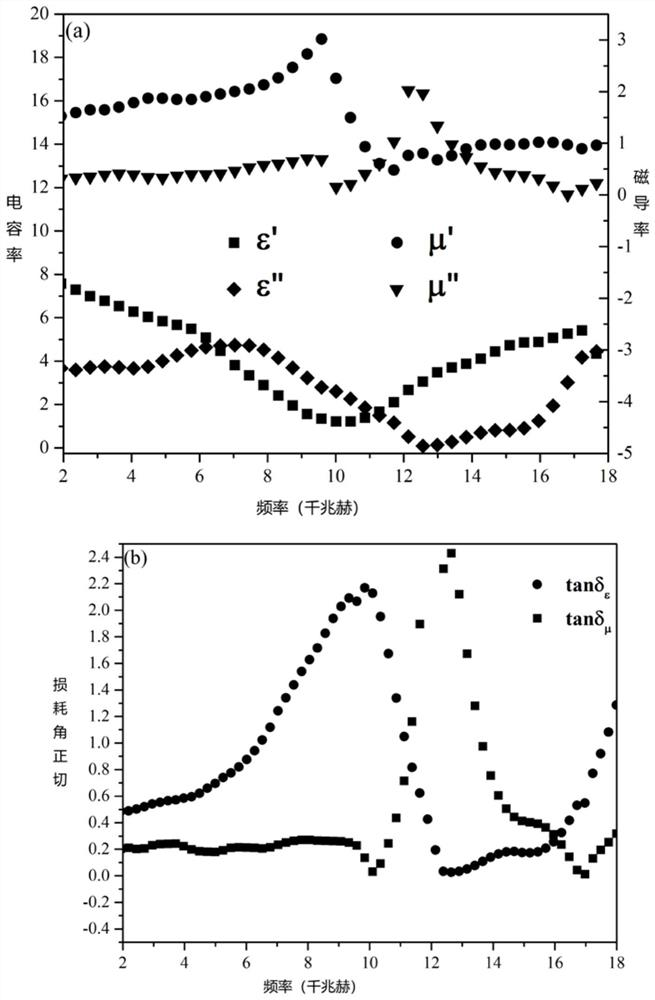

CoFe/C-CNT wave-absorbing material as well as preparation process and application thereof

A technology of C-CNT and wave-absorbing materials, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of electromagnetic wave pollution and hazards, and achieve the effect of high porosity, low density, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation process proposed in this scheme does not need to adopt a complex composite process, and the synthesis process of CoFe / C-CNT wave-absorbing materials can be completed directly through simple stirring and calcination, and the entire reaction process is carried out in aqueous solution without organic solvents, so , the invention can improve the production efficiency of the CoFe / C-CNT wave absorbing material and realize large-scale mass production.

[0047] Further, in step S1, according to molar calculation, weigh 1-5mmol Co(NO 3 ) 2 ·6H 2 O and 1-5mmolFe(NO 3 ) 3 9H 2 O and mixed in 20ml deionized water to make solution A.

[0048] Further, in step S2, 12-60 mmol of 2-methylimidazole was weighed and mixed in 80 ml of deionized water to prepare solution B according to molar weight calculation.

[0049] Further, in step S3, the cleaning solution is deionized water or absolute ethanol. Nitrate ions are easily soluble in water and absolute ethanol, and ...

Embodiment 1-4

[0058] Prepare materials according to the corresponding raw materials listed in Table 1 below, and prepare the CoFe / C-CNT wave-absorbing materials of Examples 1-4 according to the process parameters listed in Table 1 and the following steps.

[0059] S1, Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O was mixed in 20ml deionized water to prepare solution A;

[0060] S2, dissolving 2-methylimidazole in 80ml deionized water to prepare solution B;

[0061] S3, adding the solution A into the solution B for stirring, then filtering to obtain a centrifugal precipitate, washing the centrifugal precipitate with a cleaning solution, and then drying the centrifugal precipitate to obtain a MOFs precursor;

[0062] S4. Sintering the MOFs precursor prepared in step S3 under a protective gas atmosphere to prepare a CoFe / C-CNT material.

[0063] Wherein, the cleaning liquid is deionized water; the protective gas is nitrogen; the drying method is blast drying.

[0064] Table 1

[0065] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com