Modularized cross type liquid flow plant hydroponic unit, hydroponic device and hydroponic system

A cross-type, modular technology, applied in the field of plant cultivation, can solve the problems that plant roots cannot fully contact with nutrient solution and uneven plant growth, and achieve the effects of saving planting energy consumption, improving light utilization rate, and increasing planting volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

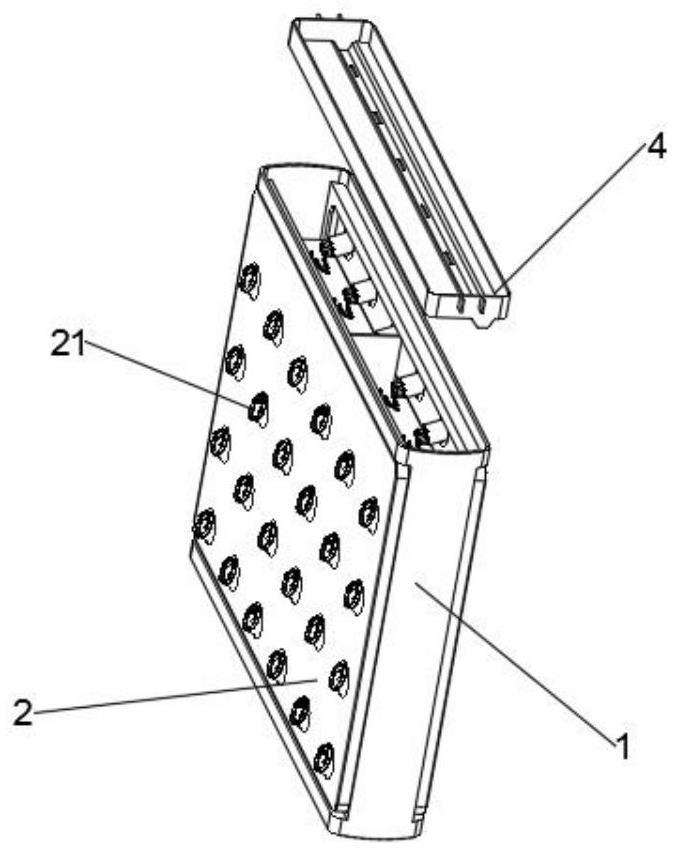

[0039] see Figure 1-5 In this embodiment, a modularized cross-flow plant hydroponic unit includes an installation frame 1, two planting plates 2 and a plurality of deflectors 3. In this embodiment, the installation frame 1 is a flat box Body structure, with space inside, the top of the installation frame 1 is provided with a water inlet 11, and the bottom of the installation frame 1 is provided with a water outlet 12;

[0040] The two opposite sides of the installation frame 1 are opened to form the installation sides, and the two planting boards 2 are respectively fixed on the installation sides, thus, the installation frame 1 and the two planting boards 2 are enclosed to form a flow cavity, and the planting boards The inner surface of 2 constitutes the side wall of the flow chamber, and the fixing method of the planting plate 2 can be fixed with the installation frame body 1 by screw fasteners, or a boss can be formed on the installation side, and the fastening of the plant...

Embodiment approach

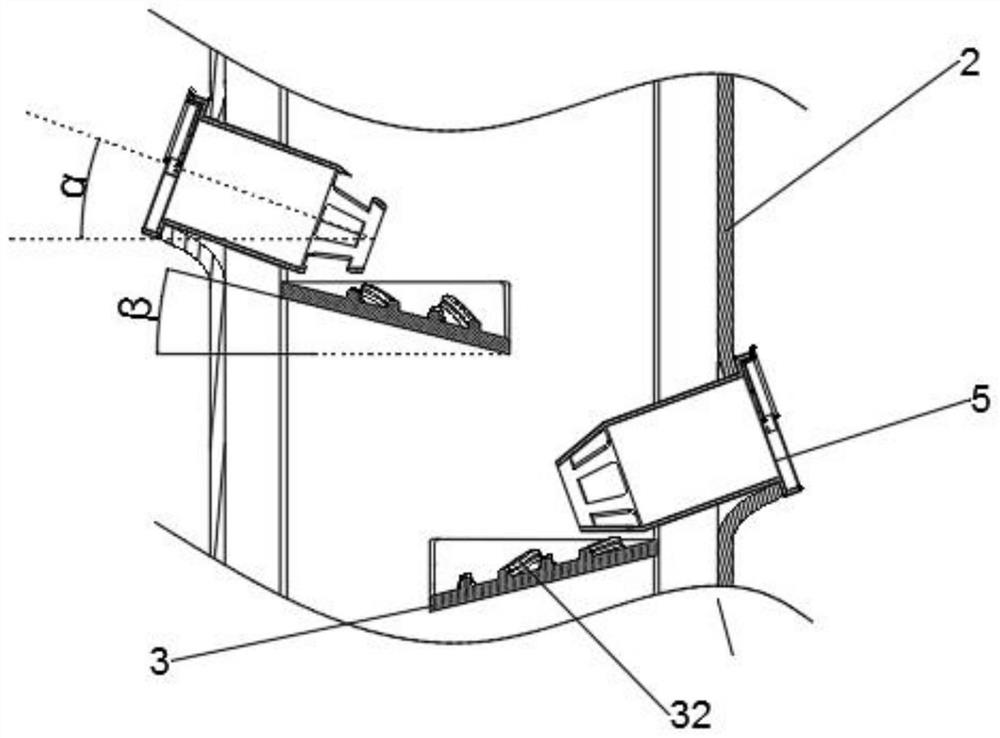

[0049] In another embodiment, the entire deflector 3 may also be arranged inclined downward.

[0050] A plurality of arc-shaped diversion ribs 32 are arranged in the diversion groove 31, and the diversion ribs 32 are extended from the side of the diversion groove 31 to the center of the diversion groove 31, and the plurality of diversion ribs 32 are intersected and dislocated. set up. The diversion ribs 32 are used to slow down the flow rate of the nutrient solution in the diversion groove 31, so that the roots can fully absorb the nutrient solution; the diversion ribs 32 can increase the attachment point of the plant root system in the diversion groove 31, so as to facilitate the fixing of the plant root system , In addition, the diversion ribs 32 arranged crosswise and misplaced can intercept part of the nutrient solution, avoiding the complete water cut off of the root system of the plant when the water supply fails, and ensuring the normal growth of the plant.

[0051] In...

Embodiment 2

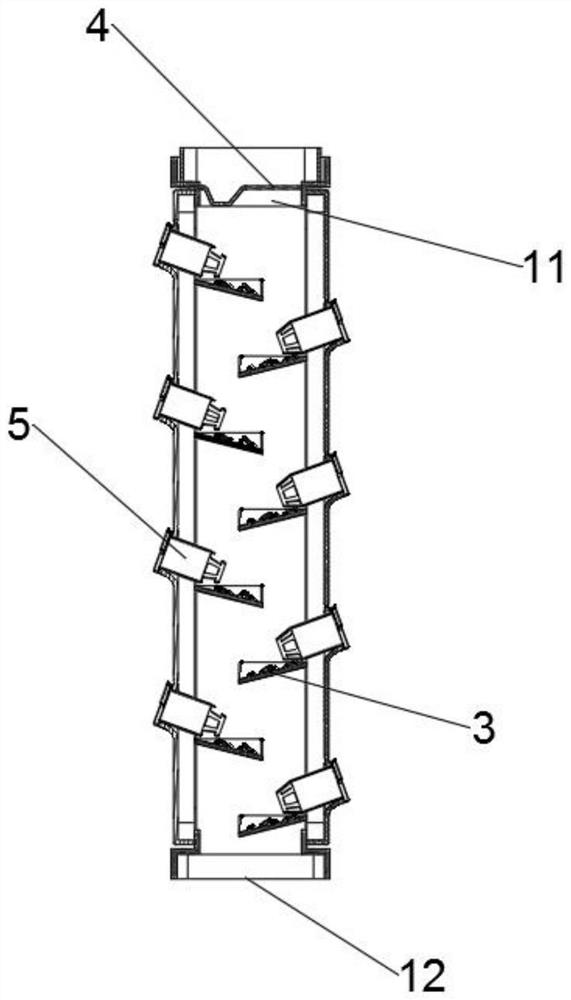

[0057] see figure 2 , 6 -9, this embodiment discloses a hydroponic device, including a support frame 7, a connecting frame 8, and a plurality of modular cross-flow plant hydroponic units 6 of Embodiment 1, and a plurality of modular cross-flow plant water The cultivation units 6 are fixed to each other in the vertical direction, and the modularized cross-flow plant hydroponic units 6 are fixed to the support frame 7 .

[0058] Specifically, the bottom end of the installation frame 1 of the modular cross-type liquid flow plant hydroponic unit 6 is provided with a connecting groove 13, and the water inlet 11 of the top floor modular cross-type liquid flow plant hydroponic unit 6 is equipped with a shunt Box 4 , the bottom surface of the distribution box 4 is provided with a plurality of distribution holes 41 at intervals, and the position of each distribution hole 41 corresponds to the position of each row of planting holes 21 on the planting plate 2 . The diversion box 4 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com