Novel spraying system

A new type of ball valve technology, applied in the field of coatings, can solve the problems of increased working hours, uncontrollable gas content, and small spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

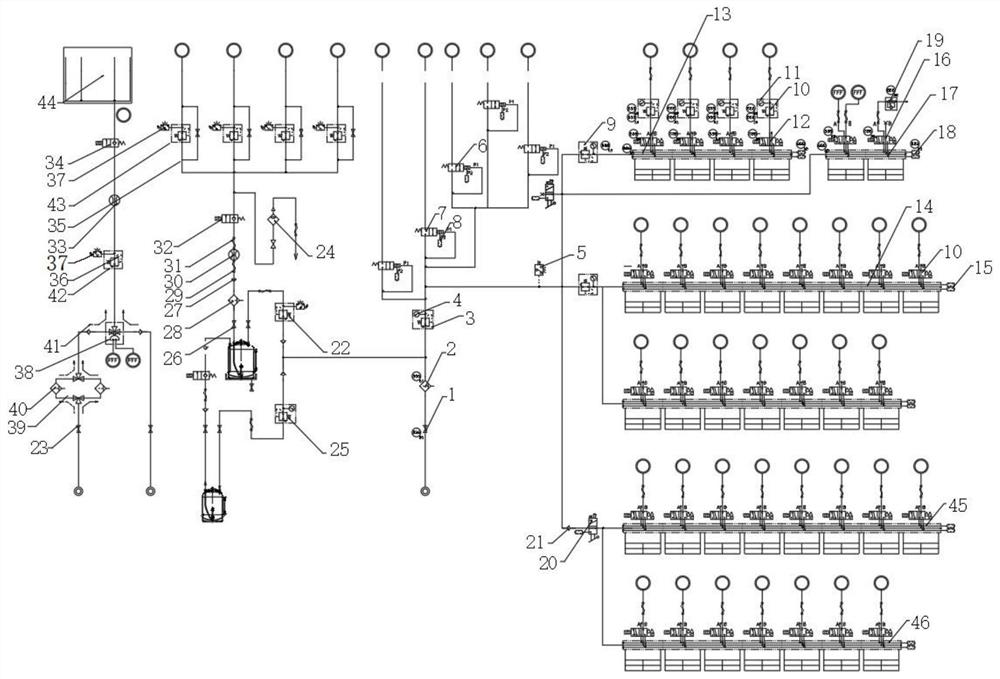

[0030] See figure 1 As shown, a technical solution provided by the present invention: a novel spraying system, the novel spraying system including a blow box 44, and the output port of the input box 44 is fixedly coupled with a sixth electromagnetic valve 34, and the sixth electromagnetic valve 34. On one side, a second flow meter 33 is provided, and one side of the second flow meter 33 is provided with a sixth pressure pressure valve 36 having a valve block 42 on one side of the sixth pressure regulating valve 36, the first The other side of the six-regulating valve 36 is provided with a second pressure switch 37, which is electrically connected to the sixth pressure reducing valve 36; a ball valve assembly, the ball valve assembly including a first ball valve 23. The third ball valve 38, the second single-directional valve 41 and the filter 40, the third ball valve 38 is disposed on one side of the sixth pressure valve 36, and the two sides of the third ball valve 38 have a firs...

Embodiment 2

[0032]A new spray system, the novel spraying system further includes a fifth pressure roller 43, and the fifth pressure roller 43 communicates with the outer conduit, and the second pressure switch 37 is provided on one side of the fifth pressure regulating valve 43. The second pressure switch 37 is coupled to the fifth pressure roller 43, and the side of the fifth modifier is provided with a variable diameter inner wire 35, and the function of the fifth pressure regulating valve 43 can be controlled. The coating input is induced to protect the internal equipment of the system, while the fifth pressure roller 43, the variable-diameter inner wire 35 and the second pressure switch 37 constitute a restriction assembly, limiting the amount of external coating, and restriction assembly can be based on It is necessary to determine the number, and the side of the variable interpolation port 35 is provided with a fifth solenoid valve 32, and a shockproof rubber 31 is provided on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com