Chain plate type cleaning device and part cleaning equipment

A cleaning device and a chain-plate type technology, which is applied in the field of parts cleaning, can solve problems such as parts displacement, parts collision, and parts temperature rise, and achieve the effect of ensuring the effect of washing and cleaning, ensuring the effect of cleaning, and maintaining the posture of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

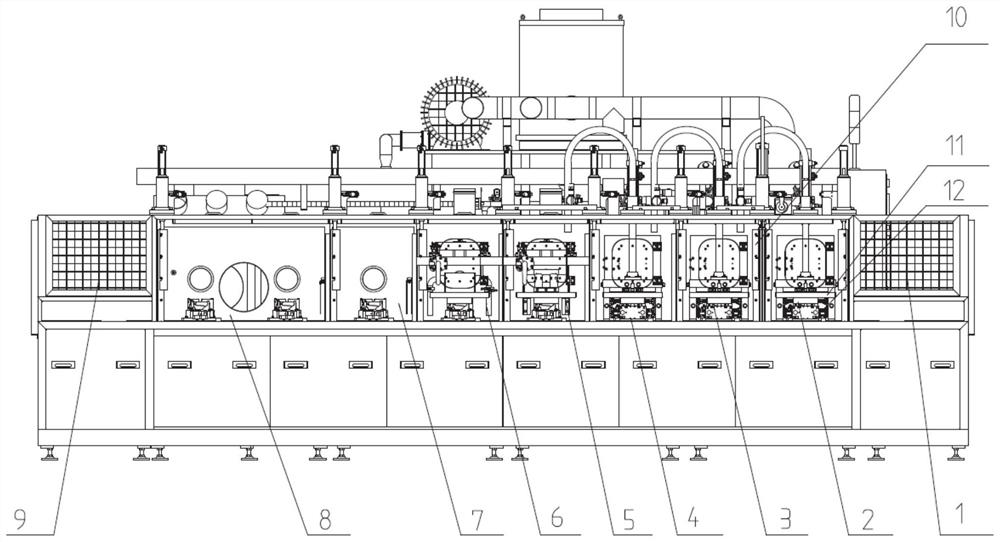

[0037] In a typical embodiment of the present invention, such as Figure 1-Figure 12 As shown, a chain plate type cleaning device is provided.

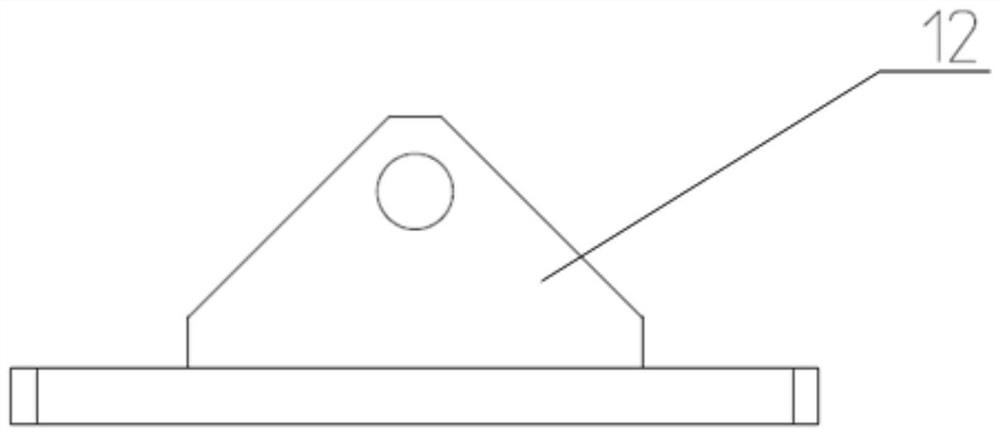

[0038] Aiming at the problem that the current parts cleaning equipment is difficult to effectively clean high-precision parts, a chain plate cleaning device 11 is provided, which is equipped with a chain plate conveying mechanism and a positioning block 12 is installed on the conveyor belt, and the position of the parts to be cleaned is constrained by the positioning block 12 , when the parts are in a stable state and transported into the cleaning area, the posture of the parts can match the position of the nozzle of the cleaning component to ensure the cleaning effect, avoid the change of the position of the parts during the flushing process, maintain the posture of the parts, and reduce the damage to the parts during the cleaning process.

[0039] The chain plate type cleaning device 11 mainly includes a chain plate conveying mechan...

Embodiment 2

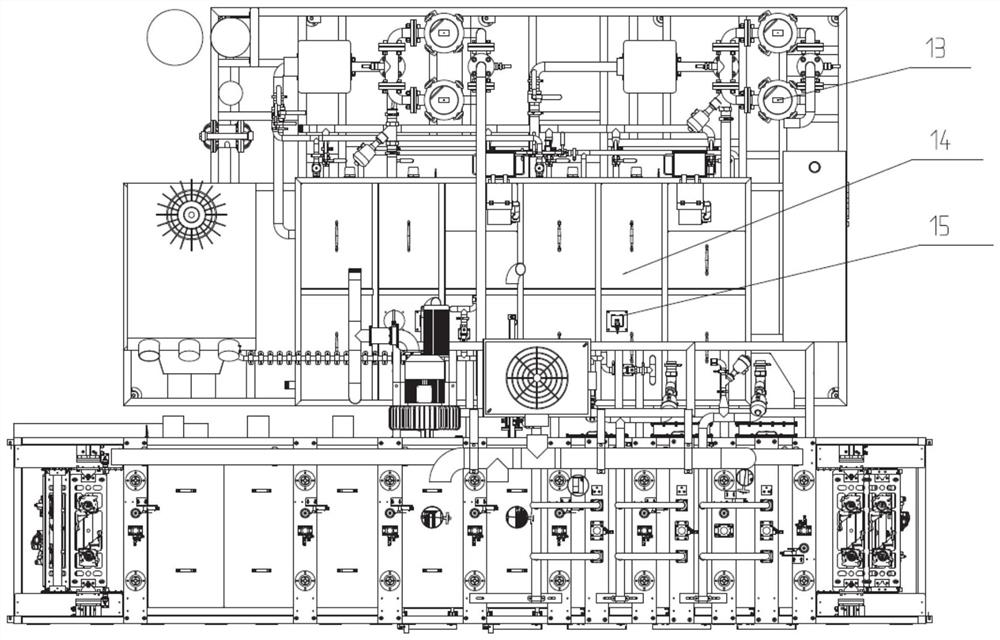

[0069] In another embodiment of the present invention, as Figure 1-Figure 12 As shown, a kind of parts cleaning equipment is provided, which utilizes the chain plate cleaning device 11 as described in Embodiment 1.

[0070] It also includes a collector, a water collection tank 14 and a water treatment device, the collector is connected to the chain plate conveying mechanism to obtain the cleaned sewage, and the water collection tank 14 is respectively connected to the collector and the water treatment device; a suspension level gauge 15 is installed in the water collection tank, The liquid level float of the suspension level gauge 15 is cylindrical, and the filter 13 can be selected as the water treatment device.

[0071] Specifically, combine figure 1 , figure 2 and Figure 12 The waste water entrained with the cleaning machine produced by the cleaning member after cleaning the workpiece is collected by the collector, and then poured into the water collection tank 14. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com