Method for efficient solidification and synergistic carbon sequestration of heavy metals in waste incineration fly ash

A waste incineration fly ash and waste incineration technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as poor solidification effect of heavy metals, low carbonation efficiency, and inability to degrade dioxins , to achieve the effect of reducing raw material transportation costs, realizing low carbon emissions, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

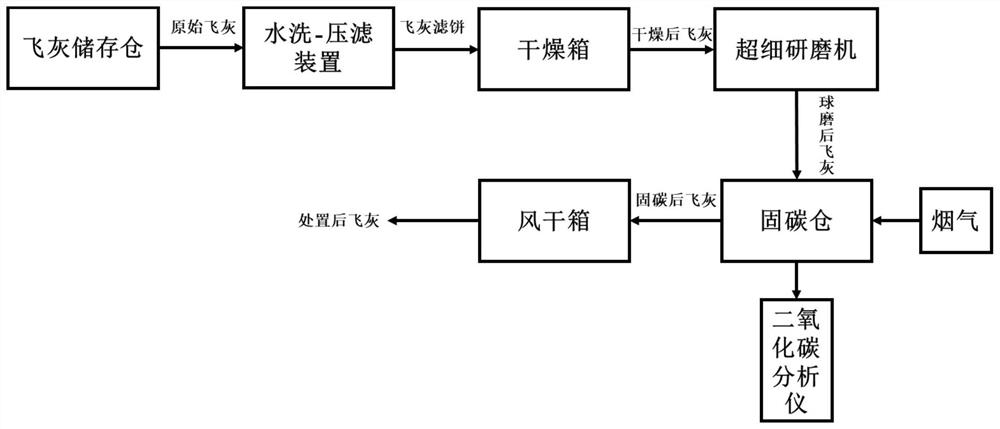

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0037] The method for high-efficiency solidification of heavy metals in waste incineration fly ash and synergistic carbon fixation in the present invention comprises the following steps:

[0038] (1) Wash the fly ash with three-stage countercurrent water, the washing time is not less than 1 hour, and the liquid-solid ratio is controlled at 3:1-5:1, the unit is L / kg; after the washed fly ash is subjected to pressure filtration, Dry at 90-105°C; control the filtration pressure to 1-2.5MPa during press-filtration, and filter for 1-2 hours; solar energy or waste heat from waste incineration power plants can be used as the heat source for drying when drying, and the drying time is not limited. less than 24 hours.

[0039] (2) Grinding the dried fly ash to an average particle size of less than 5um by mechanical ball milling, the mass ratio of steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com