Auxiliary ptfe film compounding device for preparing composite film

A composite device and composite membrane technology, which is applied in applications, household appliances, flat products, etc., can solve problems such as the difficulty in combining PTFE membranes with base membranes, and achieve the effect of reducing serious wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

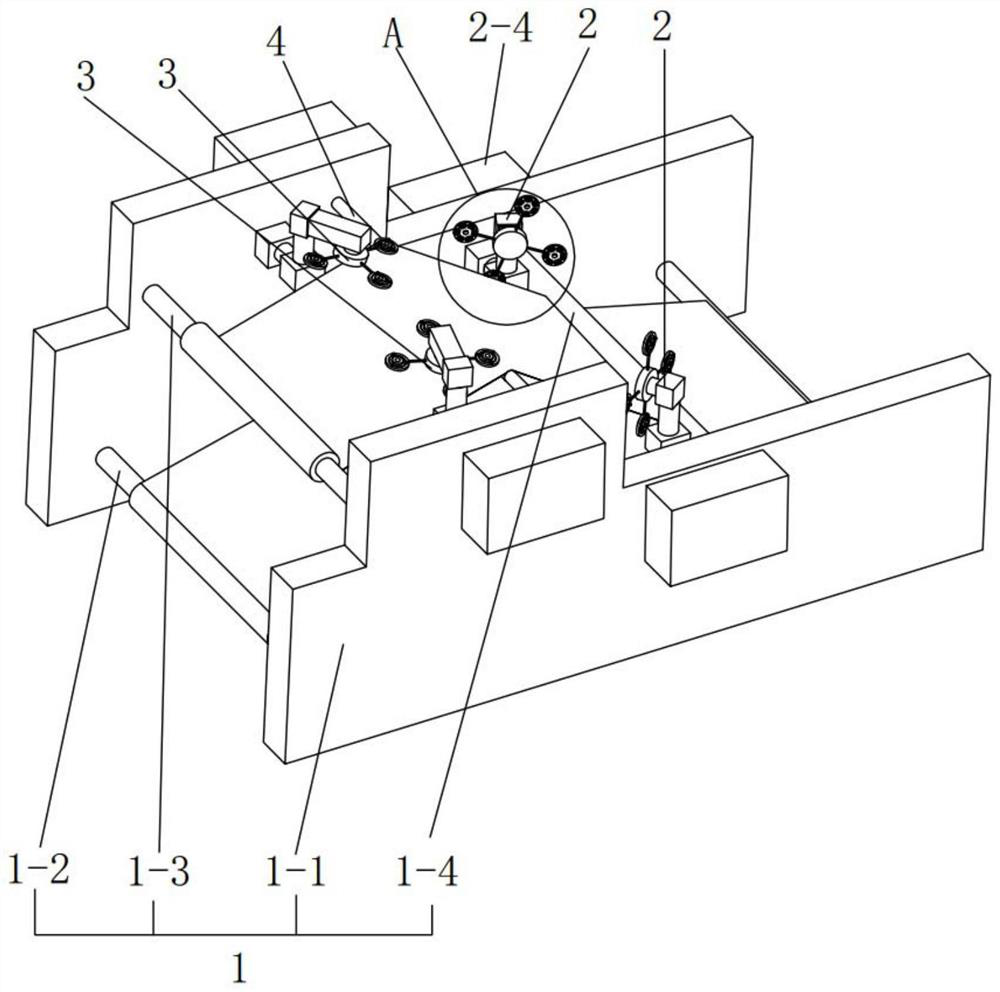

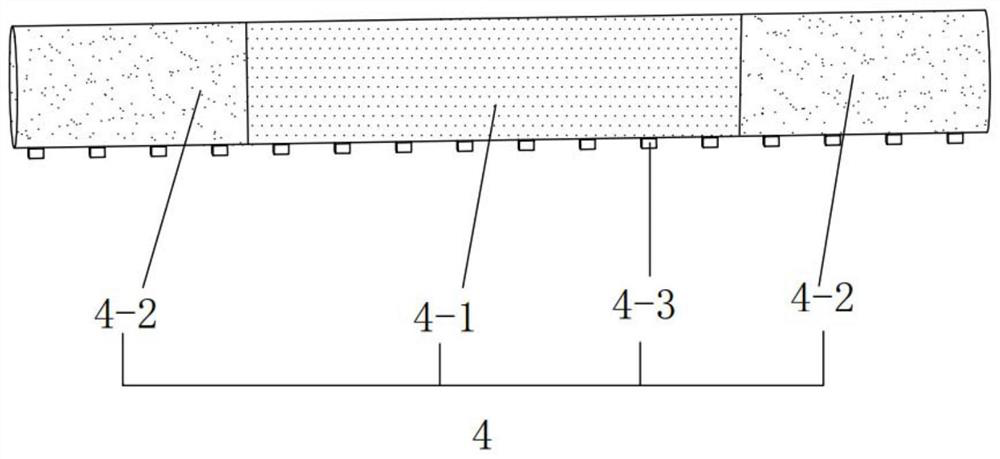

[0030] Embodiment 1: a kind of composite membrane is prepared and assisted composite device with ptfe membrane, as figure 1 and 4 As shown, the composite device is used in the roll-to-roll coating equipment 1 for realizing large-scale coil coating. The roll-to-roll coating equipment 1 includes a frame 1-1, a base film delivery roller assembly 1-2, a ptfe film Conveying roller assembly 1-3, composite roller assembly 1-4 and plc system, base film conveying roller assembly 1-2, ptfe film conveying roller assembly 1-3 are all composed of multiple sets of roller shafts that can achieve a certain displacement adjustment, composite roller Components 1-4 are composed of a pair of hot pressing rollers that can realize relative displacement adjustment and also have heating function. Composite basement membrane.

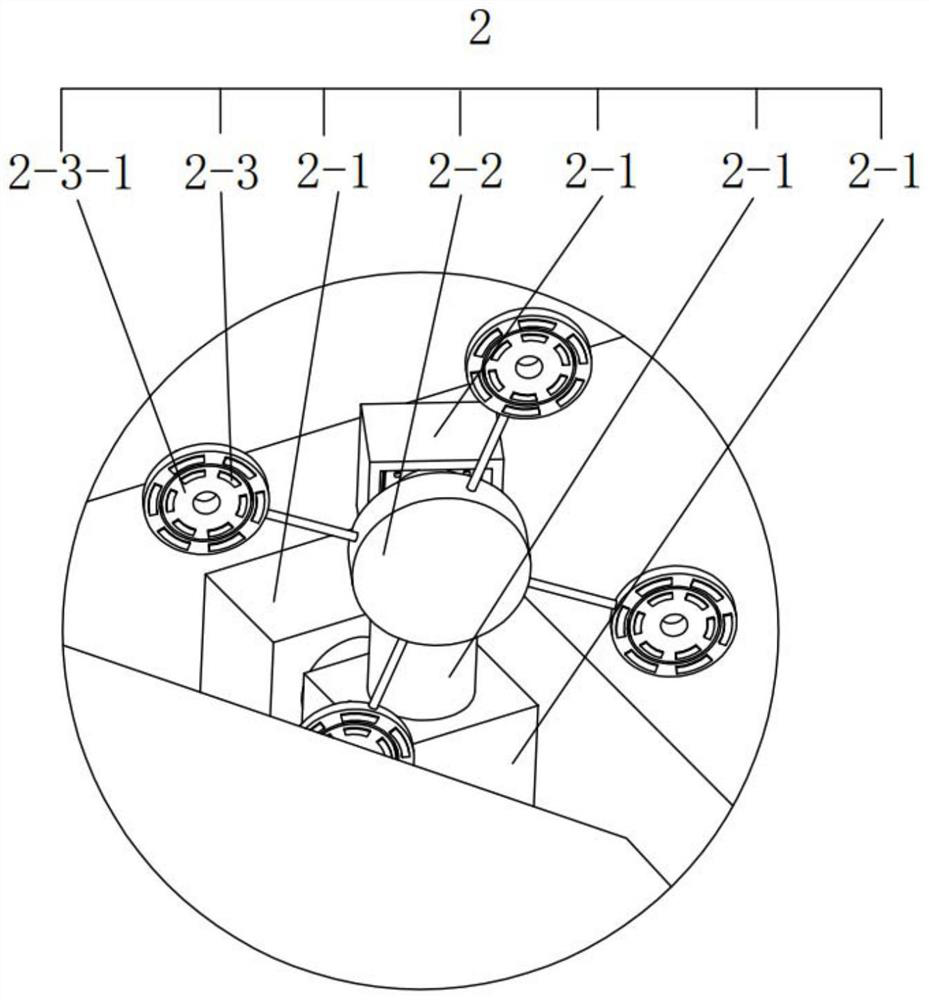

[0031] Such as figure 1 and 2 As shown, the auxiliary composite device includes a group of fine-tuning adsorption mechanisms 2 symmetrically arranged on the frame 1-1, and ...

Embodiment 2

[0035] Embodiment 2: further, such as figure 1 , 2 , 4, the frame 1-1 of the compound device is provided with a rough adjustment adsorption mechanism with the same structure as the fine adjustment adsorption mechanism 2 but with different positions, that is, the coarse adjustment adsorption mechanism also includes being fixedly arranged on the frame 1-1 The drive assembly 2-1 is provided with a turntable 2-2 for rotation on the drive assembly 2-1, and the circular array on the turntable 2-2 is provided with 4-8 adsorption discs 2-3 that act on the ptfe membrane, and the adsorption disc 2 -3 are all parallel to the turntable 2-2. In this embodiment, there are specifically four adsorption disks 2-3. The adsorption disk 2-3 is a vacuum adsorption disk 2-3, and its adsorption holes are distributed in a uniform array along the surface of the adsorption disk 2-3. The strip hole 2-3-1, each adsorption plate 2-3 is connected with the total air box 2-4 through its own air duct (not sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com