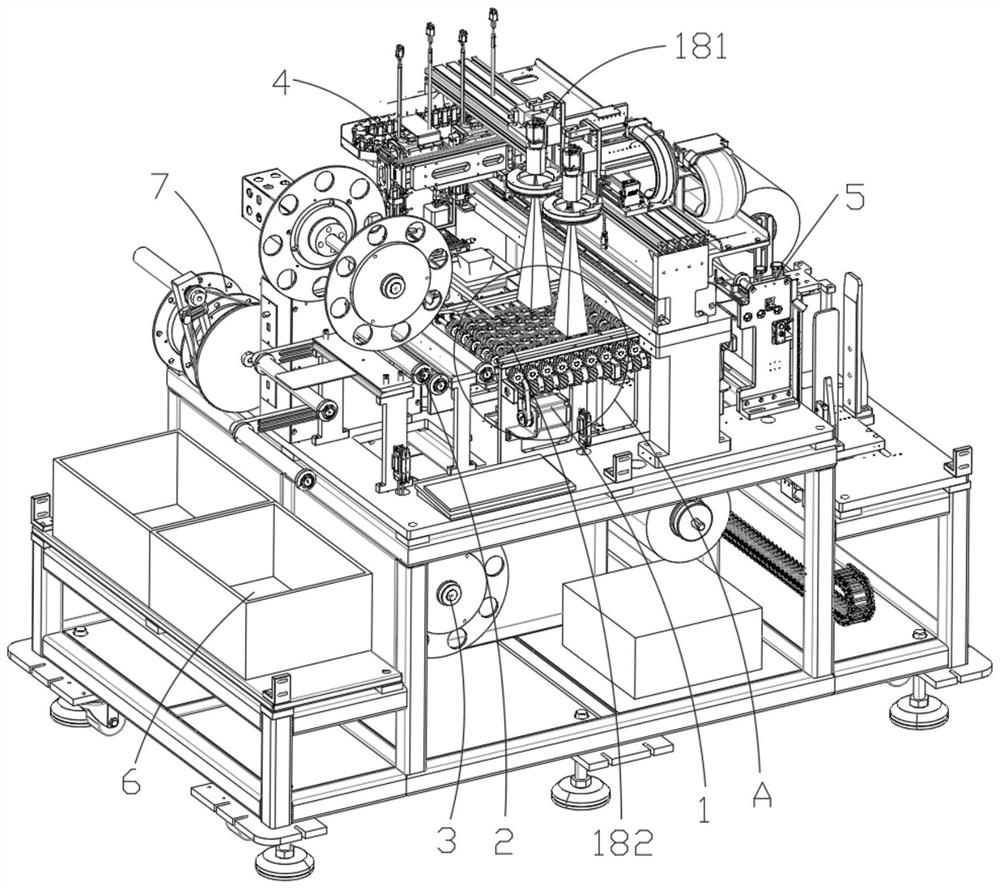

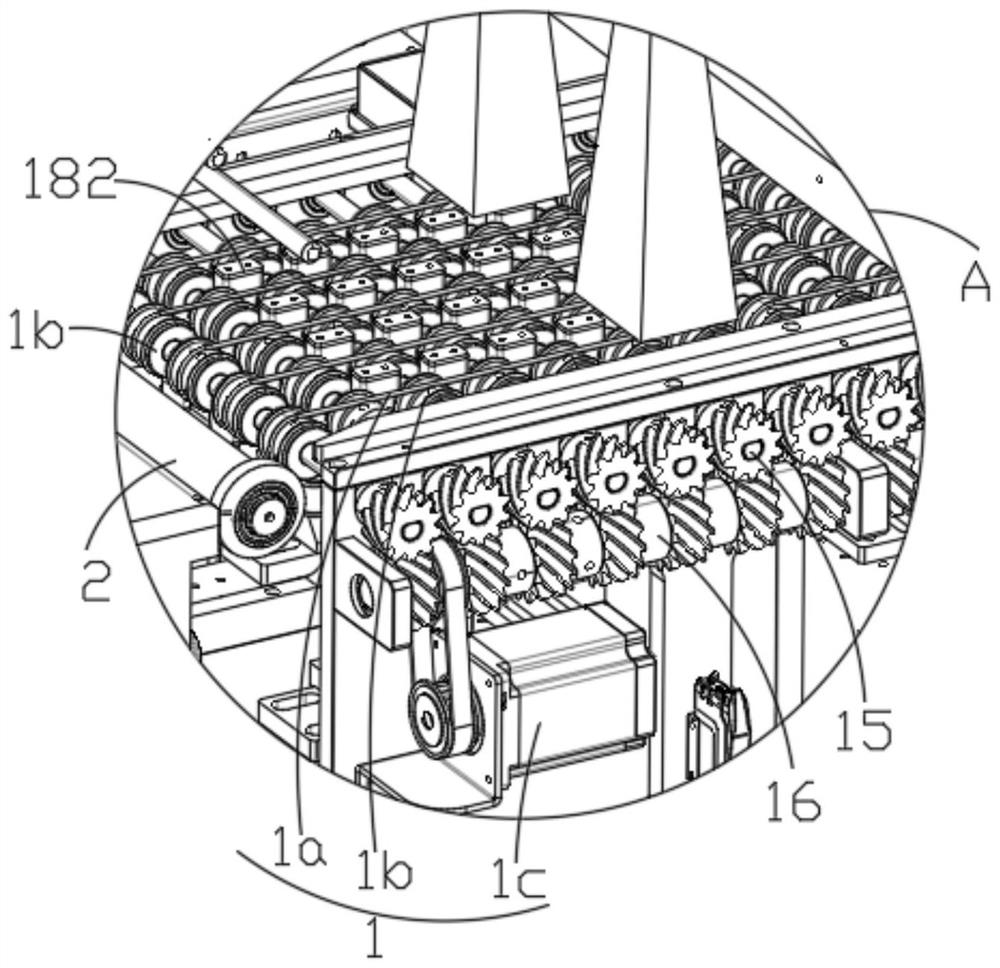

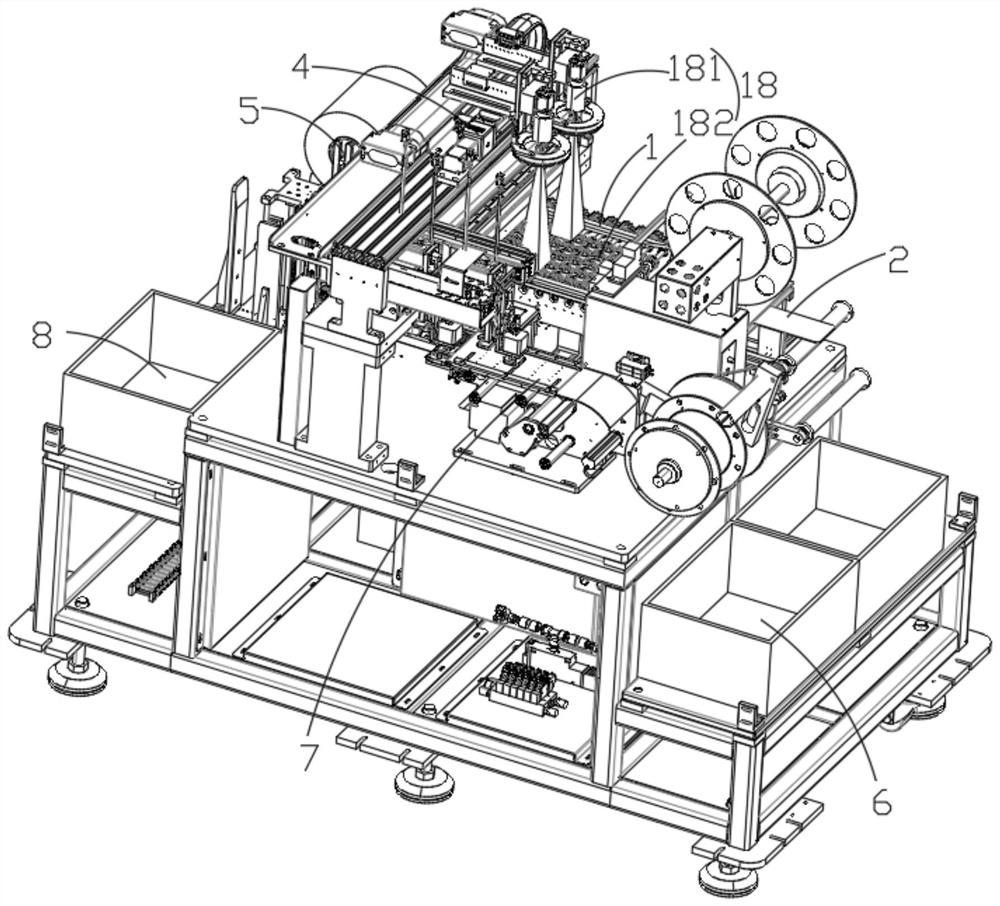

Multi-film-layer full-automatic synchronous continuous production film laminating equipment and processing method thereof

A fully automatic, multi-layer technology, applied in the direction of layered products, chemical instruments and methods, lamination, etc., can solve the problems of low efficiency, low degree of automation, low processing accuracy, etc., to ensure efficiency and production accuracy, improve The effect of increasing the degree of automation and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The description and claims of the invention and the terms "first", "second", "third", and "fourth", and the fourth, and the fourth, and the fourth ", and the fourth", and the fourth ", and the fourth", not to describe a particular order. . Moreover, the terms "including" and "have" and any variations, intended to cover the inclusion of his inclusion. For example, a series of processes, methods, systems, products, or devices that include a series of steps or units are not limited to the listed steps or units, but optionally, there is also a step or unit that is not listed, or optionally also include For these processes, methods, products, or other steps or units inherent.

[0071] The "Examples" mentioned herein means that the specific features, structures, or characteristics described in connection with the embodiments may be included in at least one embodiment of the invention. This phrase is not necessarily a separate or alternative embodiment of the same embodiment in ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com