Efficient waste collecting and cinder ladle removing device with safety design

A technology of waste collection and safety design, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of high safety hazards for workers, high risk of slag removal, high noise, etc., to achieve high reliability, reduce noise, The effect of maximizing waste collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

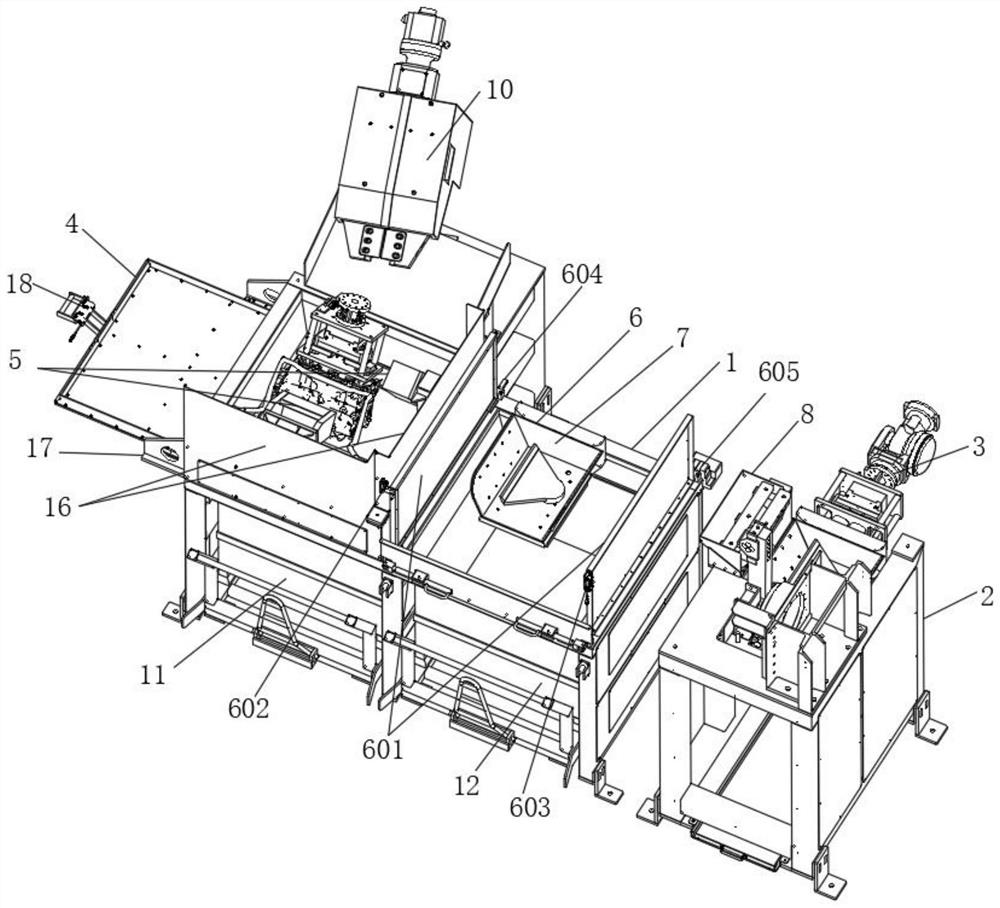

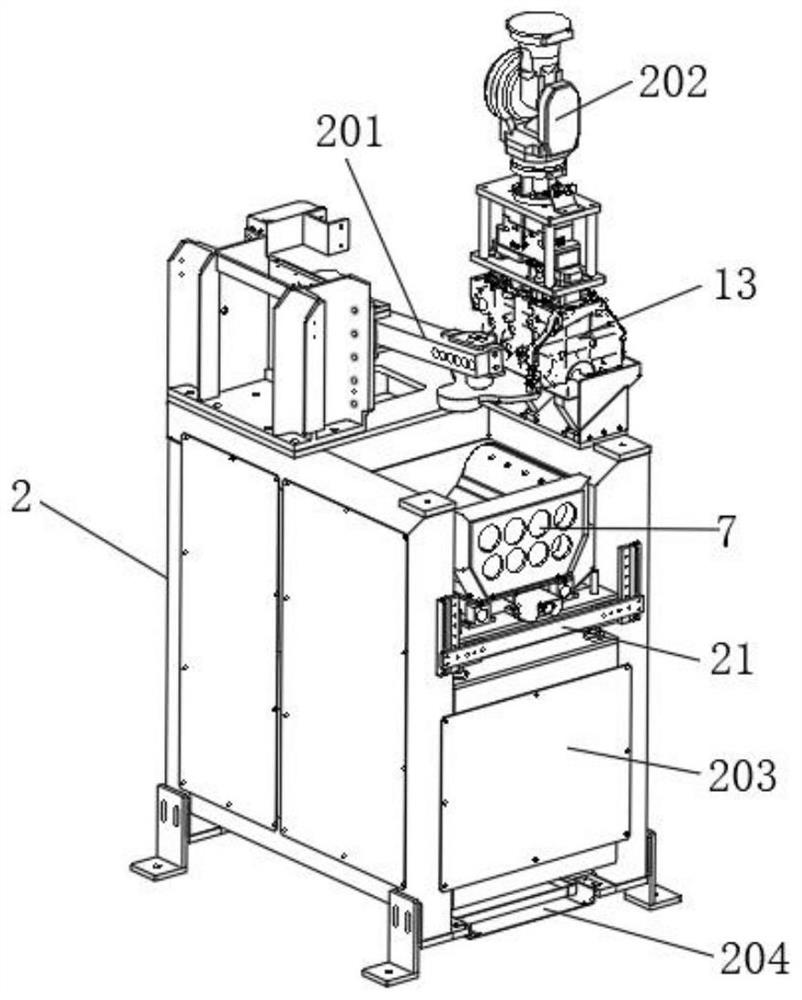

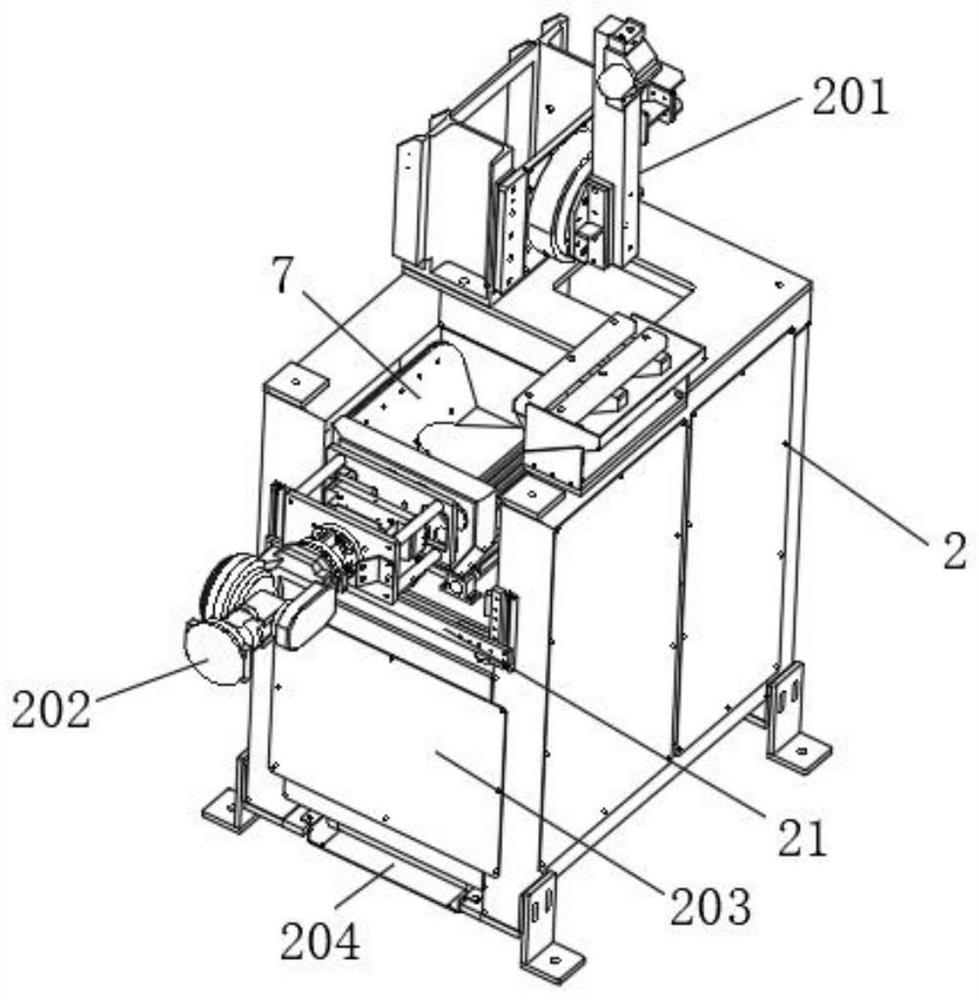

[0027] Such as Figure 1-5 As shown, a high-efficiency waste collection and slag removal device with a safe design includes a collection stand 1 and a material removal stand 2. The left side of the collection stand 1 is provided with a pull-out baffle 4, and the bottom position on the left side of the collection stand 1 is No. 1 waste trolley 11 is set, and a turning mechanism 6 is arranged on the right side of the collection platform 1. The turning mechanism 6 includes a turning baffle 601, a left closing safety lock 602, a right closing safety lock 603, a left opening limit switch 604 and Open the limit switch 605 on the right, the bottom position on the right side of the collection platform 1 is provided with No. Shaped slag bag collision block 5, the middle position of collection platform 1 is also provided with profiling slag bag collision block 5, casting fixture 8 is arranged on material removal platform 2, and the upper position of casting fixture 8 is set on material ...

Embodiment 2

[0029] Such as Figure 6-7As shown, in order to facilitate the installation of the cake tray 7, the bottom surface of the cake tray 7 is provided with a positioning seat 701, and the bottom surface of the cake tray 7 is provided with V-shaped positioning blocks 702 on the left and right sides of the positioning seat 701. The tray base 21 Guide rod 22 is arranged on the top, and the quantity of guide rod 22 is two, and the front and rear positions of guide rod 22 are provided with support 29, and the tray base 21 is provided with waste baffle plate 27 at the left and right sides of guide rod 22. The front and rear positions of the base 21 are provided with connecting plates 24, the tray base 21 is provided with an adjustment seat 25 at the inner side of the connecting plate 24 at the front, and the tray base 21 is located at the inner side of the connecting plate 24 at the rear. Position is provided with rear side baffle plate 28, and the left and right sides position of connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com