Damp-proof device for equipment in machine room

An equipment and equipment room technology, applied in the field of equipment moisture-proof devices in equipment rooms, can solve problems such as equipment corrosion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

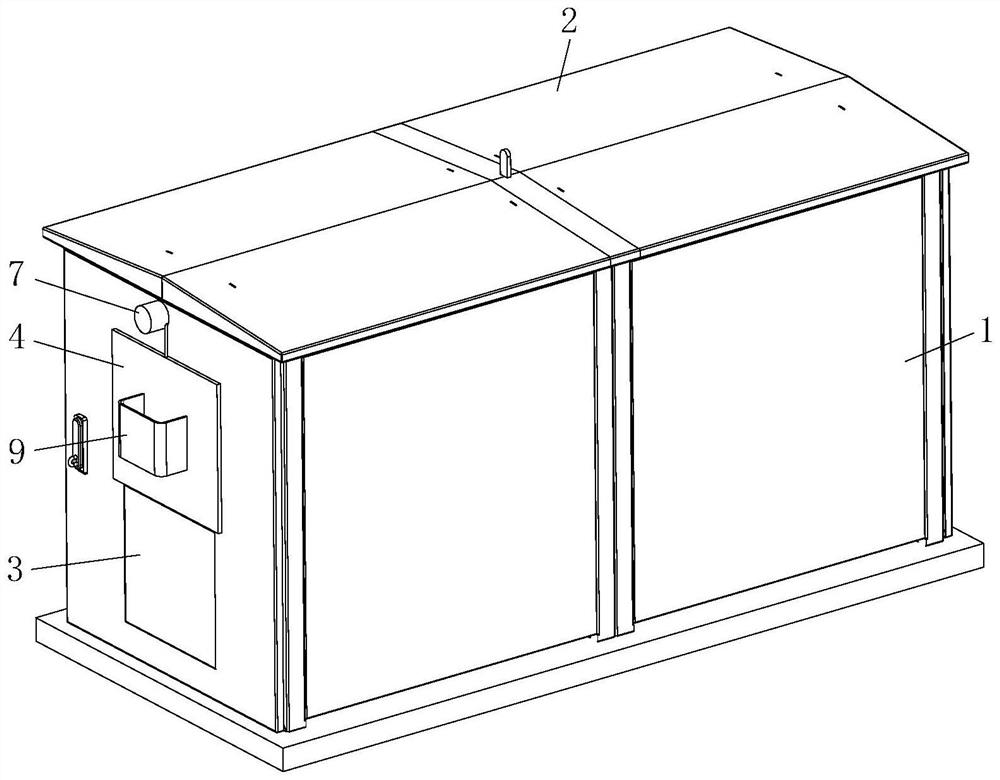

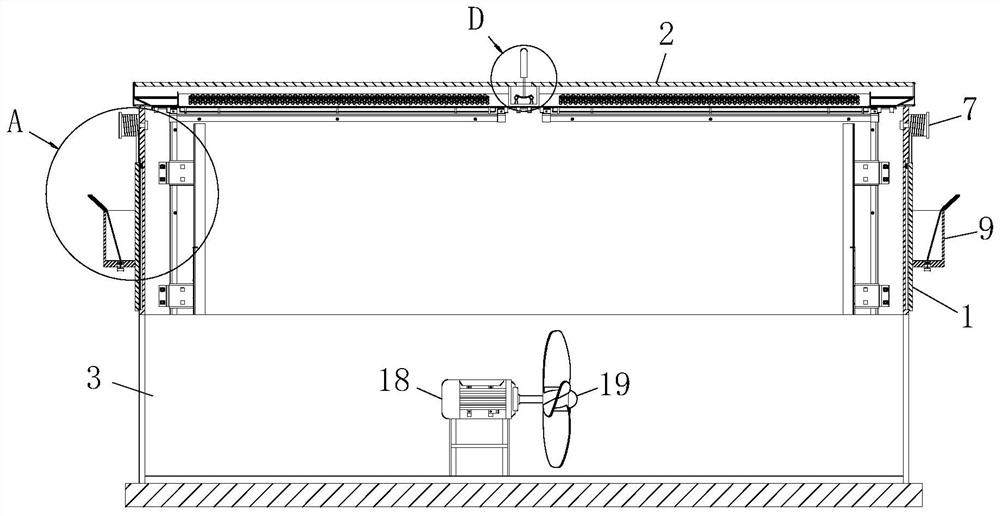

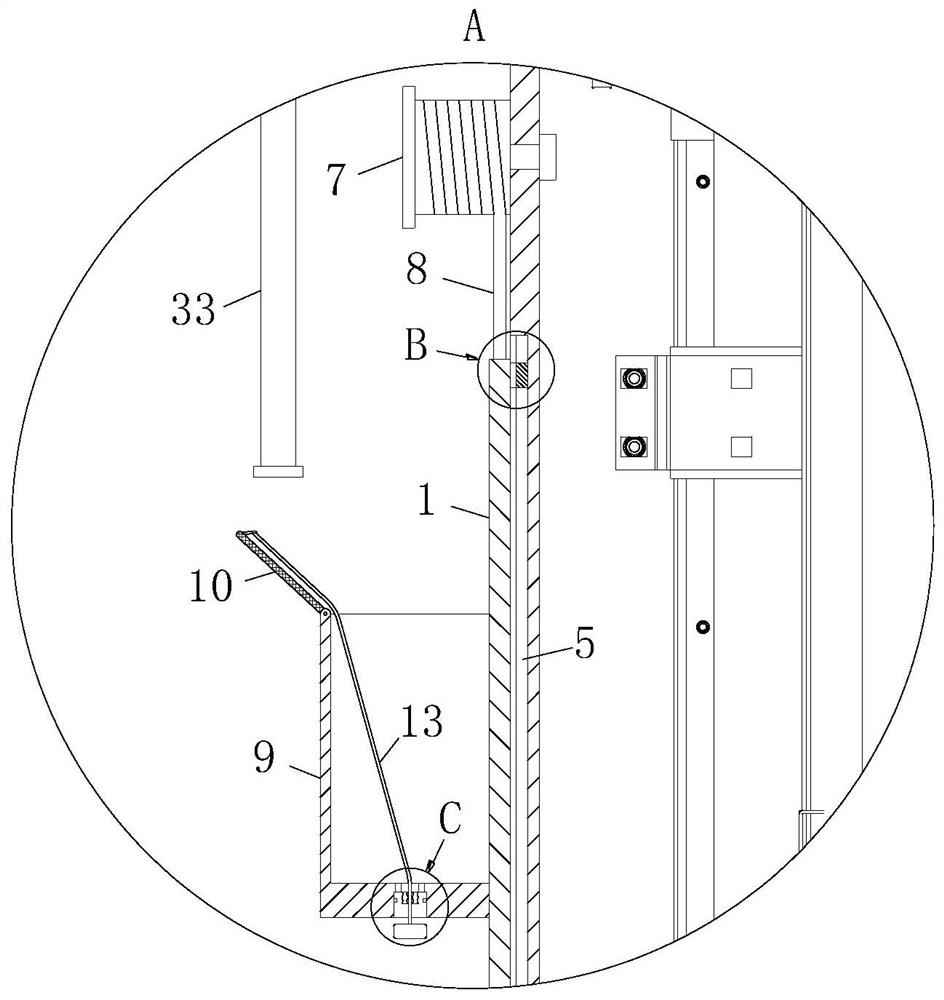

[0032] Such as Figure 1 to 5As shown in a moisture-proof room equipment apparatus according to the present invention, comprises a body 1 housing; the housing body 1 is attached to the top plate 2; 1 on both sides of the housing body 3 defines a vent; the vents the upper movable plate 43 is provided; position close to the housing body 1 of the movable plate 4 defines a chute 5; 5 slidably connected to the slider chute 6, 6 and the slider 4 and the movable plate solid bonding; the housing 4 above the movable plate 1 is rotated by a torsion spring connected to reel 7; 7 on the reel and fixed to the connection cord 8 is wound One, One and the other end connected to the rope 8 activity plate 4 is fixed; the movable plate 4 is fixed to the outer water tank 9, and a water tank 9 is provided with leakage component; when it rains, rain water into the collection tank 9, a greater force of gravity, slide down the drive plate 4 3 and the automatic vent sealing to prevent moist air through a v...

Embodiment 2

[0042] Such as Figure 8 As shown in Comparative Example a, wherein another embodiment of the present invention are: the catheter 27 has elasticity, and the catheter 27 away from the curved section of the electrical contact sheet 23 is curved coiled; by conduit 27 to a curved coiled, resilient conduit 27 can be increased, so that the arcuate link 21 is driven by the rotation of the electric contact 23, not to be bound by a conduit 27, to ensure the smooth operation of the rotation.

[0043] Working principle: when it rains, rain water into the collection tank 9, a greater force of gravity, slide down the drive plate 4 and the self-sealing vents 3, to avoid moist air through a vent into the interior of the engine room 3, storm after the rain water tank 9 from leaking through the leak down assembly, the reel 7 is rotated and the connection cord One effect of the torsion spring 8 in the retractor, and then pull on the move the movable plate 4, so that the engine room through a natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com