Gas hybrid bearing based on turbine engine

A gas mixing and bearing technology, which is applied in the direction of air cushion bearings, engine components, machines/engines, etc., can solve the problems that the turbine engine affects the working stability, and achieve the effect of avoiding friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

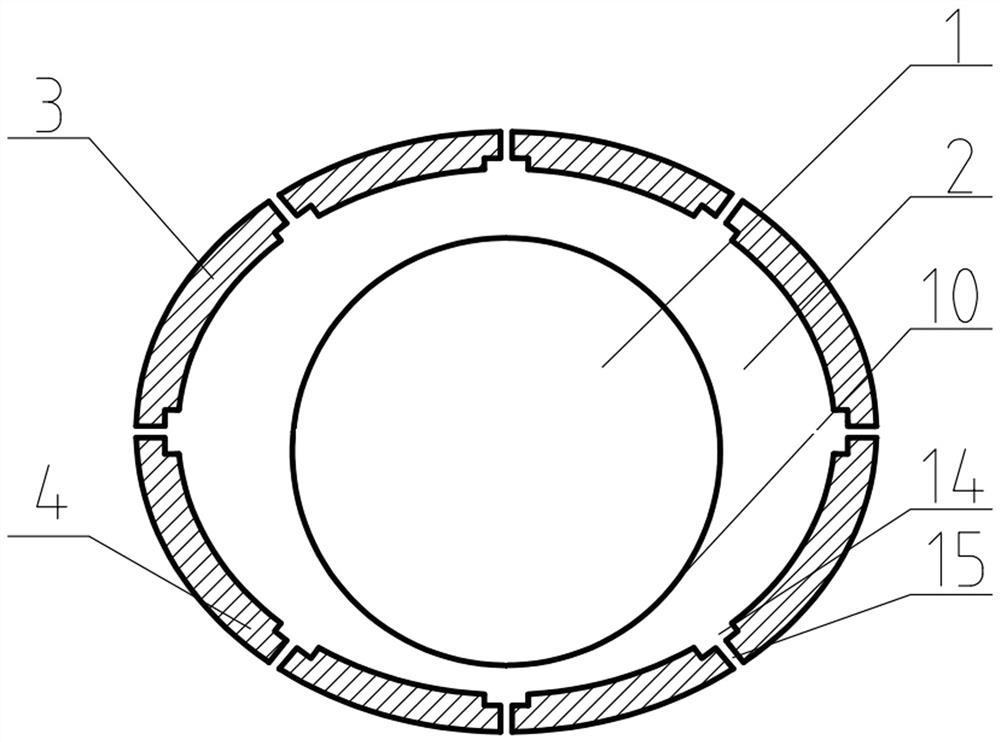

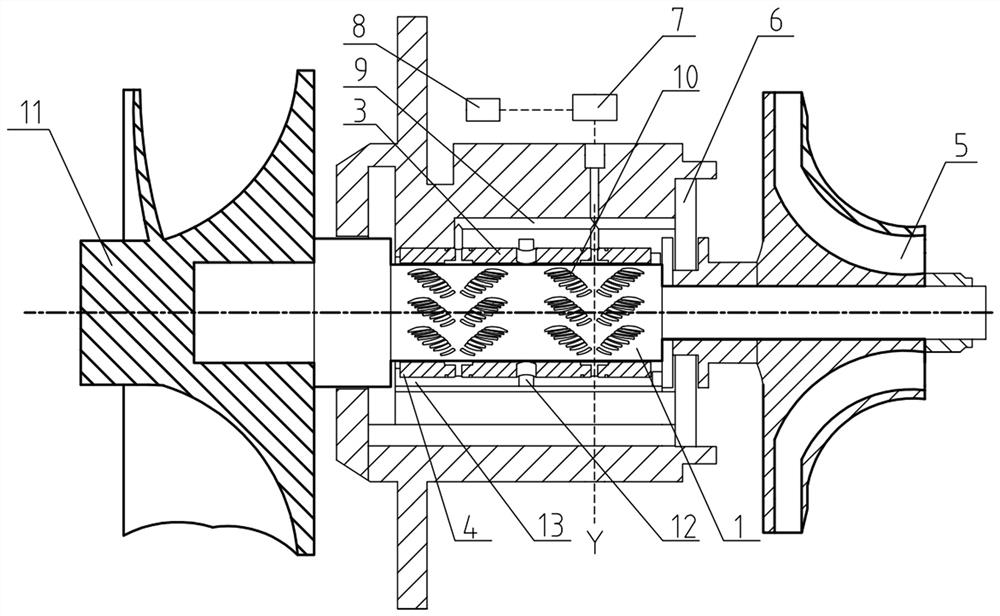

[0028] A gas hybrid bearing based on a turbine engine, as shown in the figure, includes a main shaft 1 , an upper half 3 of an elliptical bearing bush and a lower half 4 of an elliptical bearing bush. Both ends of the main shaft 1 are respectively provided with a row of groove groups composed of a plurality of wedge-shaped grooves 10 , the two rows of groove groups are parallel to each other and the center line of each groove group is perpendicular to the axis of the main shaft 1 .

[0029] Specifically look at a single groove 10, such as figure 2 As mentioned above, multiple specifications including the same outline and different sizes are arranged on the outer surface of the main shaft 1 in order from small to large. The grooves 10 are distributed along the Y line, that is, the centerline of the groove group is mirror-symmetrical, and a single groove 10 is arranged obliquely compared to the centerline of the groove, and the transverse length of each groove 10 is less than f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com