Metal and rubber combined type vibration isolation device of space remote sensing camera and installation method of metal and rubber combined type vibration isolation device

A remote sensing camera, metal rubber technology, applied to the camera body, camera, spring assembly composed of several springs, etc., can solve the problem that the vibration isolation device cannot achieve the ideal vibration isolation effect, and the vibration isolation equipment is catastrophic. Compression is difficult to control and other problems, to achieve the effect of simple structure, low cost, and change the vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

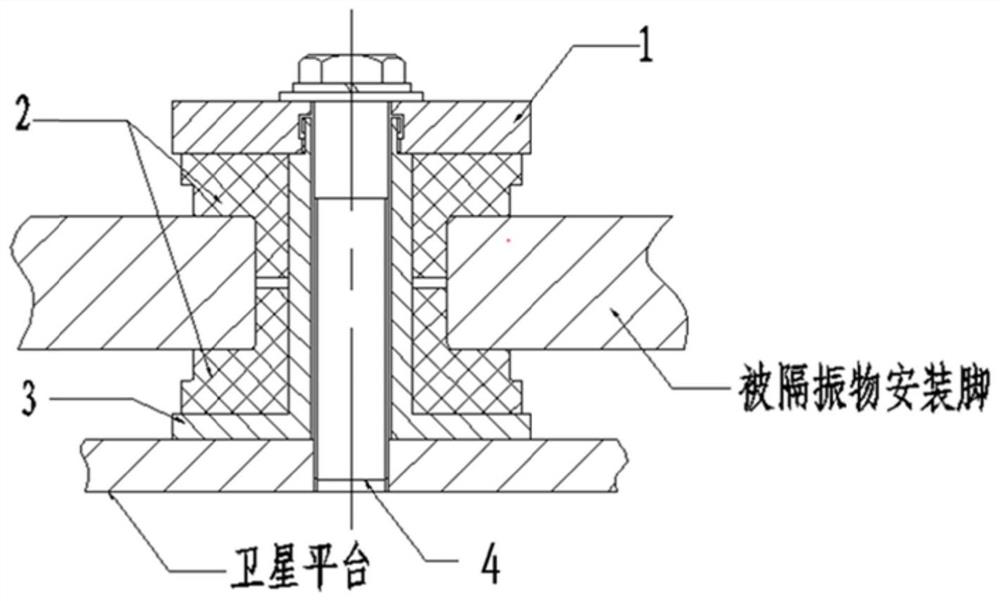

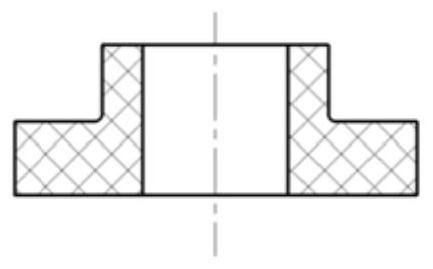

[0057] In this embodiment, a metal-rubber combined vibration isolation device for a space remote sensor is suitable for a space remote sensing camera, including a limit cover plate 1, two rubber pads 2, a mandrel bottom plate 3 and a fastening screw 4;

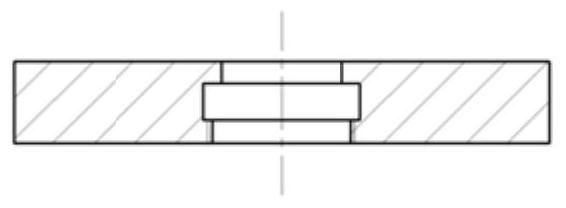

[0058] The limit cover plate 1 is a circular ring structure, and the circular hole part of the circular ring is composed of a section of internal thread and two circular holes. Arrange threaded holes and two round holes in sequence from bottom to top, and record them as threaded hole segment, first round hole segment and second round hole segment in turn, and the major diameter of the internal thread of the threaded hole segment is smaller than the round hole of the first round hole segment The inner diameter is greater than the inner diameter of the second circular hole segment, such as figure 2 As shown; in this example, the limiting cover plate 1 is made of the same material as the mandrel bottom plate 3, which is process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com