Array substrate, manufacturing method of array substrate and display device

A technology of array substrate and substrate substrate, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as the reduction of aperture ratio, achieve high aperture ratio, ensure display quality, and eliminate the effects of color resistance grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

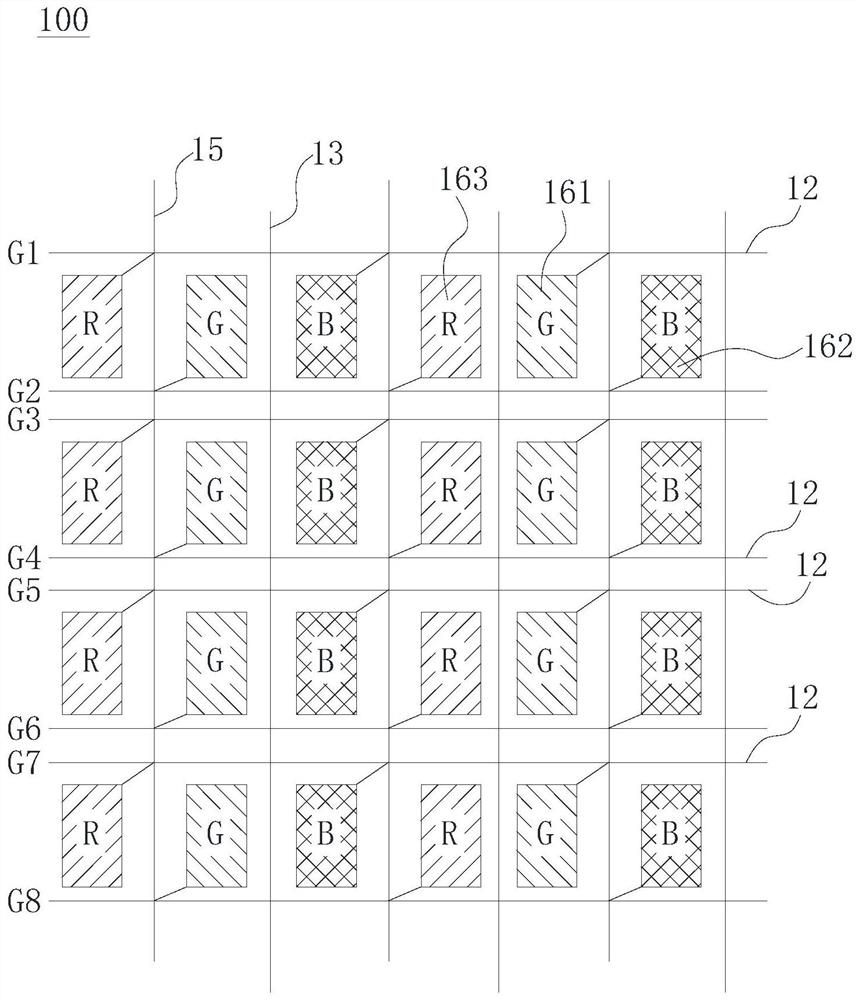

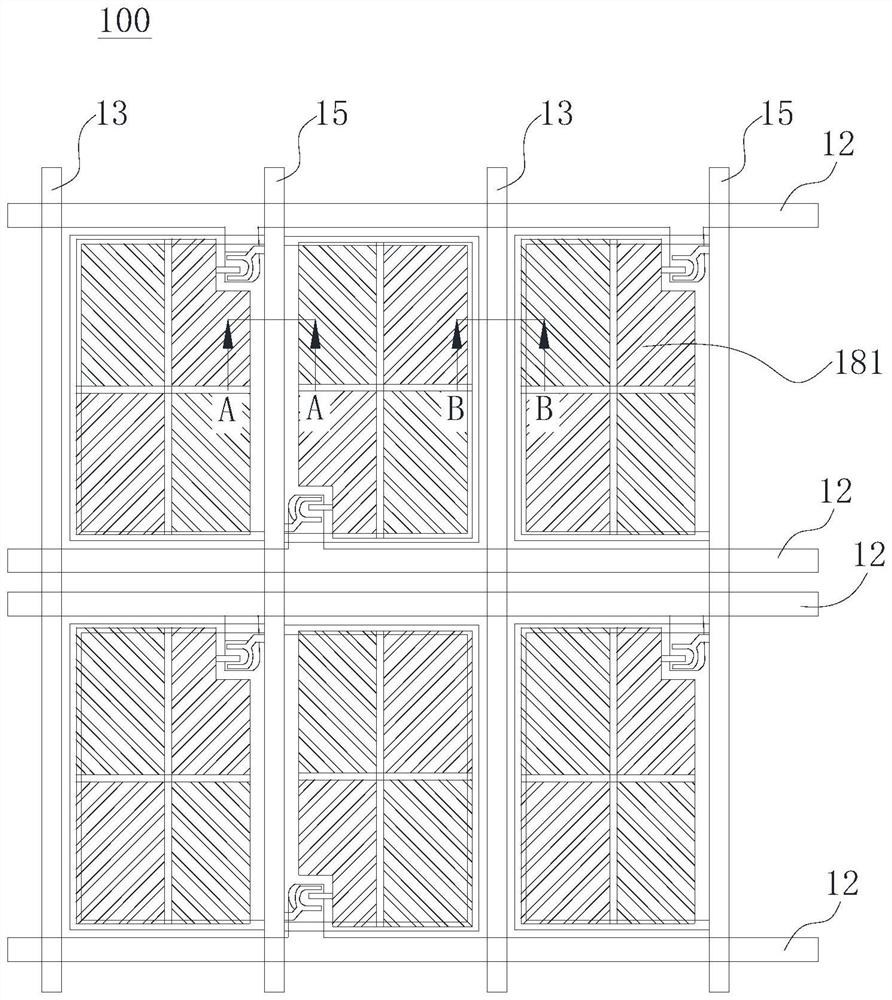

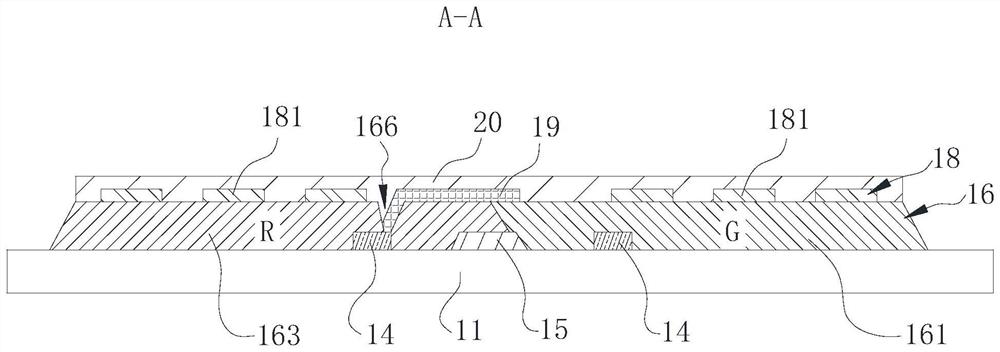

[0047] First, see figure 1 , image 3and Figure 4 As shown, Embodiment 1 of the present application provides an array substrate 100, which includes: a first base substrate 11, a common electrode line 13 and a data line 15 disposed on the first base substrate 11, and a common electrode line 13 disposed on the first base substrate 11. and the color resist layer 16 on the data line 15 , and the pixel electrode layer 18 disposed on the color resist layer 16 . Therefore, the array substrate 100 is a COT type array substrate.

[0048] Wherein, the color-resist layer 16 includes a plurality of color-resist blocks of different colors, namely a first color-resist block 161 , a second color-resist block 162 and a third color-resist block 163 . Such as figure 1 , figure 2 and Figure 4 As shown, the first color resistance block 161 and the second color resistance block 162 are adjacent in the direction perpendicular to the data line 15, and the edges of the two are located above ...

Embodiment 2

[0071] see Figure 5 As shown, compared with the first embodiment, the array substrate 100 provided by the second embodiment further includes a covering portion 172 disposed below the light shielding electrode 19 and above the color resist layer 16, that is, the covering portion 172 is formed on the first On the overlapping edges of the color-resist block 161 and the third color-resist block 163 , the light-shielding electrode 19 is further formed on the cover portion 172 .

[0072] The covering portion 172 is specifically strip-shaped and parallel to the data line 15 .

[0073]The purpose of this setting is that when the color-resist layer 16 is formed, it is necessary to deposit and etch color-resist material layers of different colors in multiple times, for example, first deposit and etch to form an R color-resist block, then deposit and etch to form a G color-resist block , and finally deposited and etched to form the B color-resist block, then, the edge of the first colo...

Embodiment 3

[0080] Figure 6 and Figure 7 Shown is the third embodiment of the array substrate 100 provided by the present application. The difference from the first and second embodiments above is that the flat layer 17 is generally a whole layer arranged between the pixel electrode layer 18 and the color resist layer 16 structure. Such as image 3 As shown, in addition to the filling portion 171 filling the color-resisting groove 160 and the covering portion 172 covering the overlapping edges of the first color-resisting block 161 and the third color-resisting block 163, the planar layer 17 also includes Each color resist block and the flat portion 173 above the filling portion 171 . Of course, it can be understood that the flat portion 173 needs to avoid the above-mentioned first via hole 166 and the second via hole.

[0081] That is to say, before forming the pixel electrode layer 18 and the light-shielding electrode 19, the color-resist trench 160 is filled with the flat layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com