Grinding system for montmorillonite powder

A technology of montmorillonite powdering and grinding, which is applied in the direction of grain processing, etc., can solve problems such as crushing, and achieve the effect of simple removal, flexible use, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

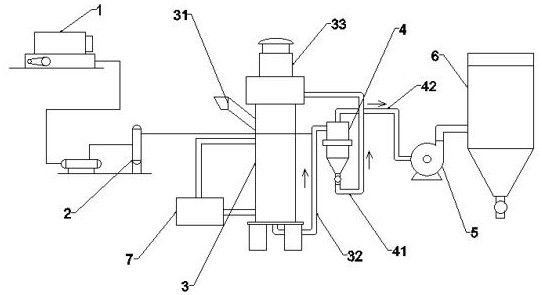

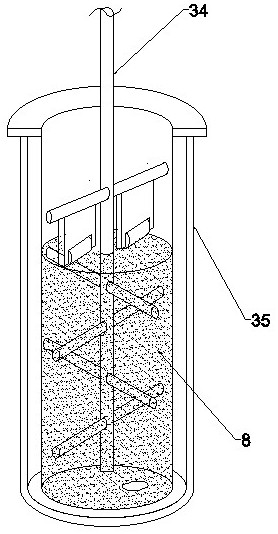

[0037] Such as figure 1 What is shown is a powder grinding system for montmorillonite, which is used to solve the problem that impurities in grinding aids are easily introduced in the grinding stage of the prior art, and cannot be effectively removed through additional separation steps. This application includes : stirring mill 3, classifier 4, drying bin 6, wherein stirring mill 3 operates under low temperature environment, and the abrasive material mixed with montmorillonite powder and grinding aid is finely ground in stirring mill 3, and the grinding aid used The agent is not traditional hard particles, but ice particles, which have high hardness in low temperature environment and can evaporate during the drying process, which directly avoids the introduction of new impurities, ensures the purity of the final product, and saves The extra sorting step is eliminated, and the ice particles as a grinding aid can maintain the low-temperature environment in the stirring mill 3 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com