Laser penetration welding galvanized sheet equipment and welding method

A welding method and galvanized sheet technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of safety hazards, inclusion of pores, etc., and achieve the effects of avoiding crack tendency, reducing welding defects, and efficient welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

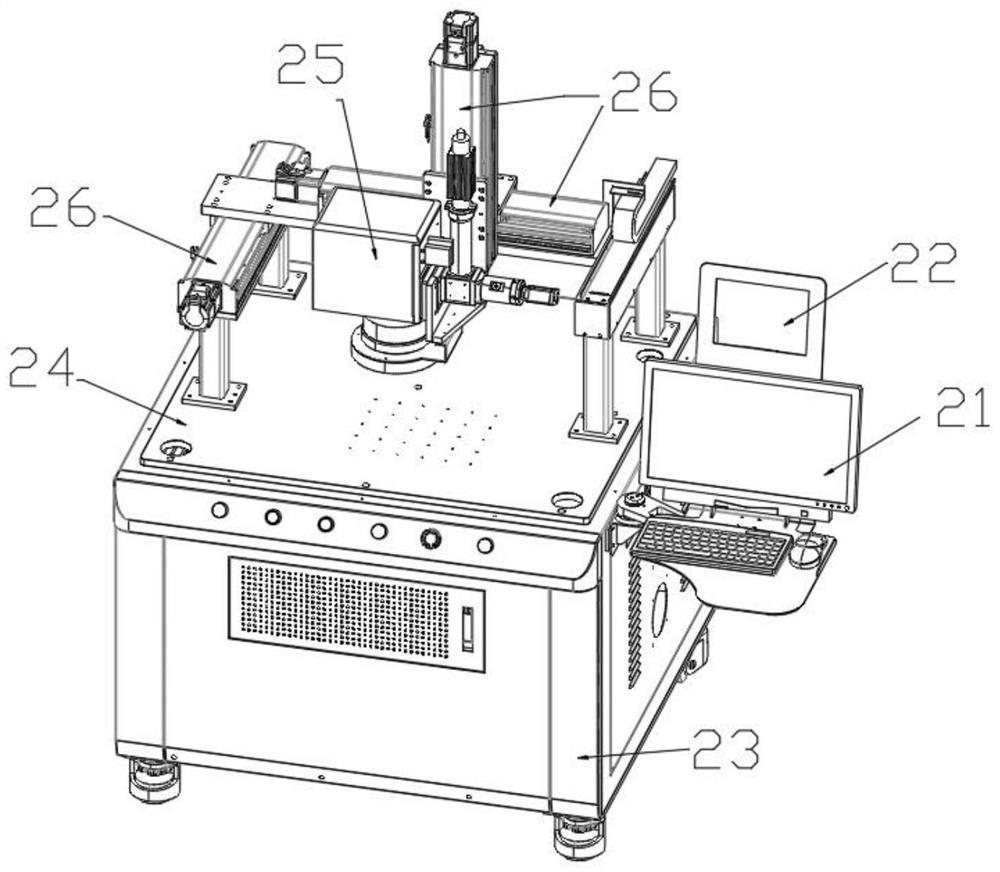

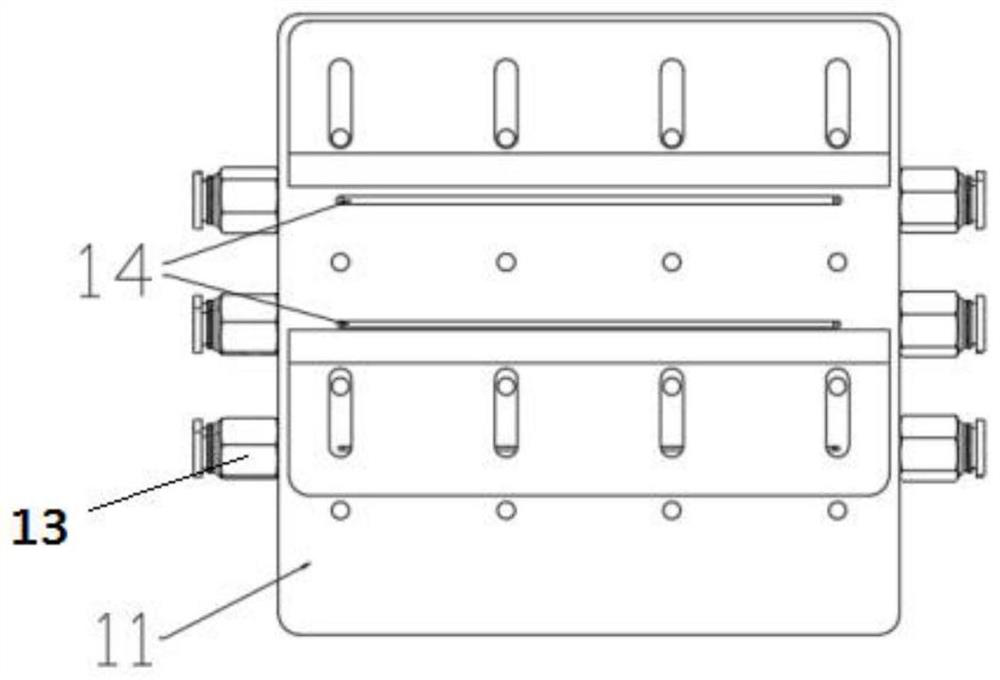

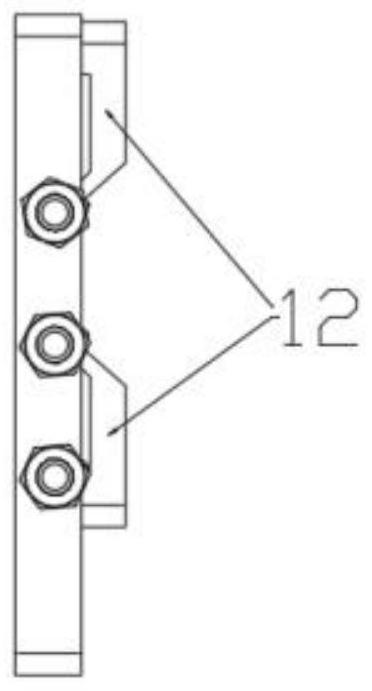

[0039] Put a piece of A4 paper flat between two galvanized sheets, arrange the galvanized sheets according to the position requirements, and use the pressing fixture to fix the galvanized sheets; import the welding pattern into the welding software of the electric control cabinet , place the clamping fixture of the galvanized sheet on the workbench 24, and fix the pressing fixture at a fixed position below the vibrating head 25; Wipe it clean and air-dry; set the slow down on the electric control cabinet, reserve 5mm length for straight line welding, slow down the power to end, the air blowing tank 14 blows protective gas at the bottom of the galvanized sheet, and the vibrating head 25 completes the welding with a low power output of 400W The surface of the part is preheated, and the deep penetration welding of the part to be welded is completed with a high power output of 2100W. The interval between two steps of welding is 300ms. 40mm / s.

Embodiment 2

[0041]Put a piece of A4 paper flat between two galvanized sheets, arrange the galvanized sheets according to the position requirements, and use the pressing fixture to fix the galvanized sheets; import the welding pattern into the welding software of the electric control cabinet , place the clamping fixture of the galvanized sheet on the workbench 24, and fix the pressing fixture at a fixed position below the vibrating head 25; Wipe clean and air-dry; set the slow down on the electric control cabinet, reserve a 30° angle for the slow down to finish, the air blowing tank 14 blows protective gas at the bottom of the galvanized sheet, and the vibrating head 25 completes the part to be welded with a low power output of 500W Preheat the surface of the welding surface, complete the deep penetration welding of the part to be welded with a high power output of 2500W, the interval between two steps of welding is 300ms, the swing width of the beam in the vibrating head 25 is 1.2mm, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com