Polishing device with pressing and holding mechanism

A technology of a pressing mechanism and a grinding mechanism, which is applied in the directions of grinding machine parts, grinding feed motion, grinding workpiece supports, etc., can solve problems such as inconsistent product quality, achieve high work efficiency, reduce feeding procedures, The effect of simplifying the feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

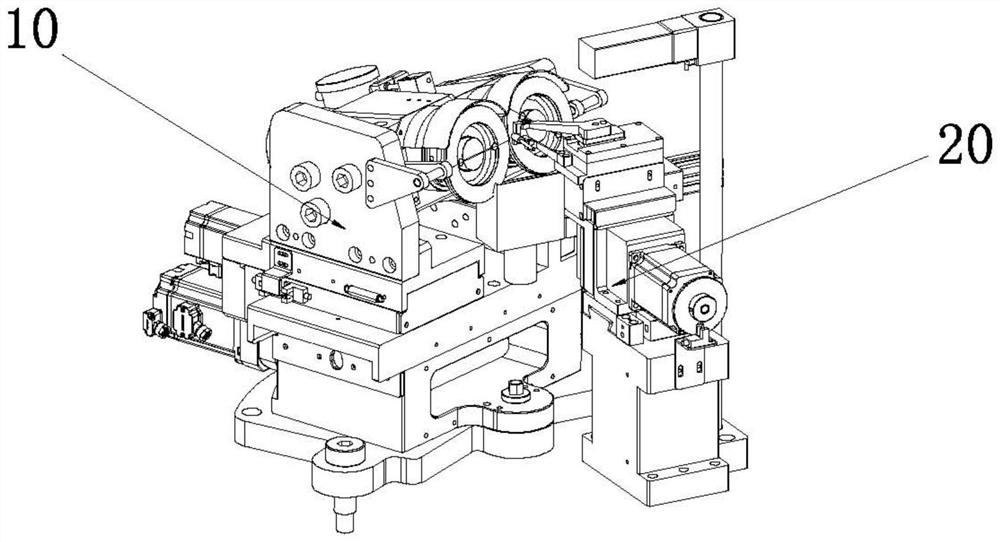

[0034] A specific embodiment of a grinding device with a pressing mechanism of the present application, the grinding device includes a grinding mechanism 10 and a pressing mechanism 20 , and the pressing mechanism 20 is arranged on the side of the grinding mechanism 10 . It should be noted that the holding mechanism 20 is used to hold the material (material rod), and the grinding mechanism 10 is used to grind the material. The following is a description of the grinding mechanism 10 and the holding mechanism 20 .

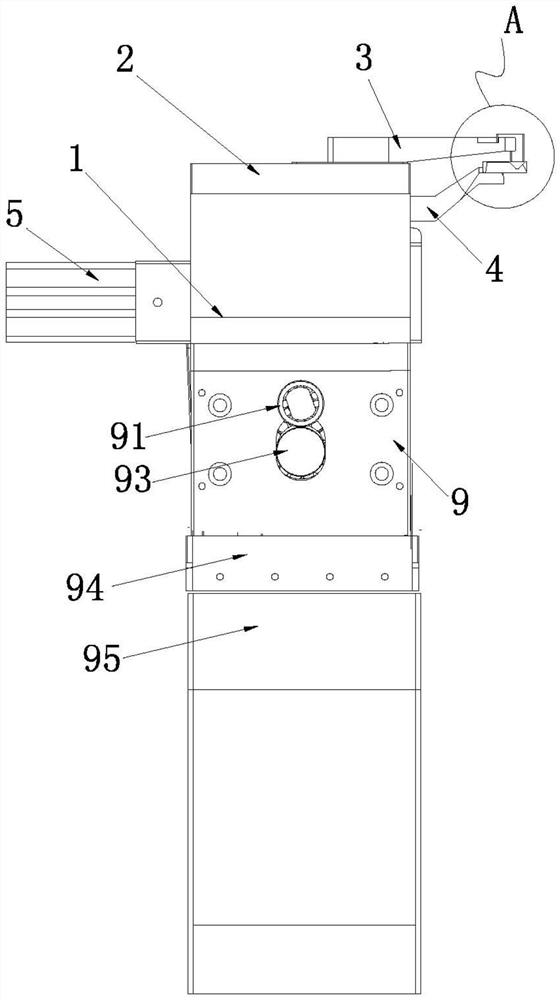

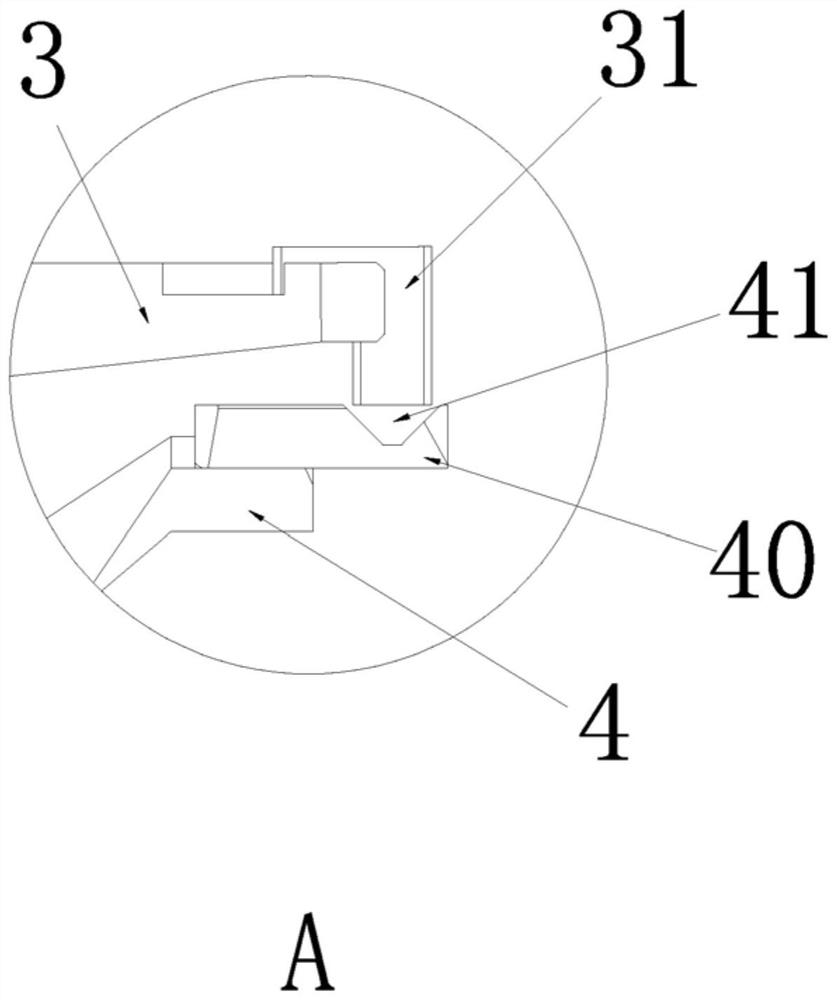

[0035] Such as figure 2 As shown, the pressing mechanism 20 includes an upper pressing arm 3 , a lower pressing arm 4 , a hollow base 1 and a top plate 2 fixedly installed above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com