Motor rotor production and processing equipment and production and processing method thereof

A technology for processing equipment and motor rotors, applied in metal processing equipment, grinding/polishing equipment, manufacturing stator/rotor bodies, etc., can solve problems such as reduced work efficiency, inflexible use, inconvenience, etc. Good grinding effect and convenient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

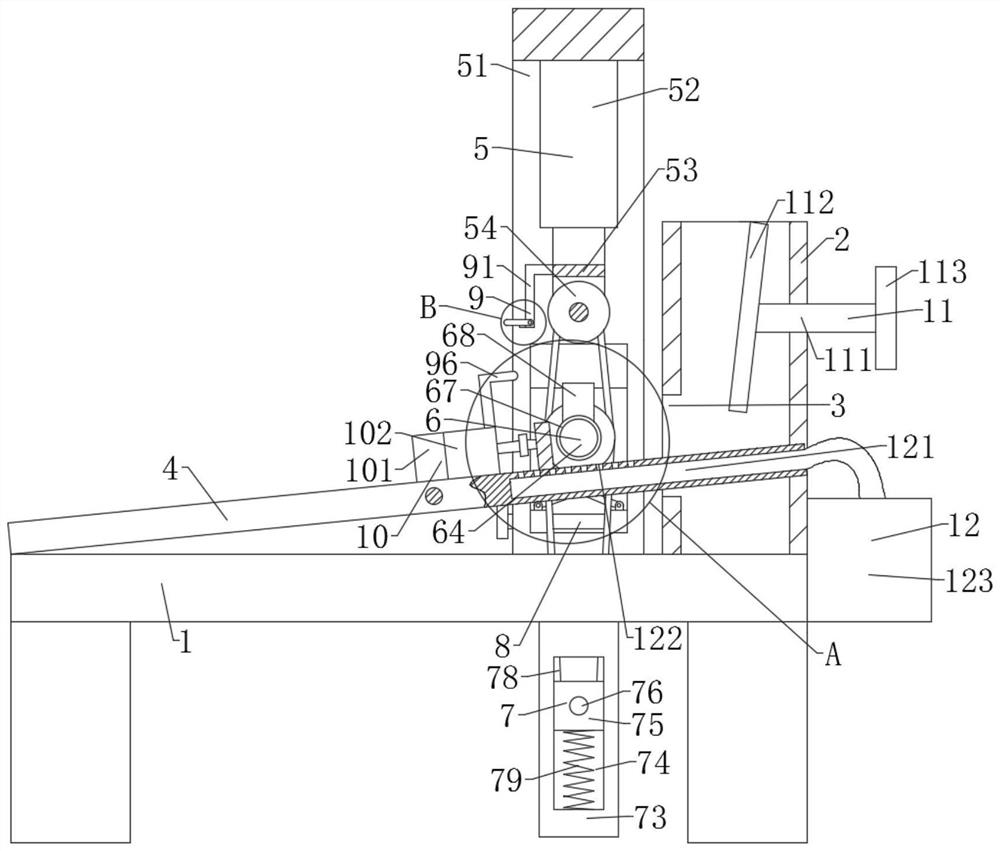

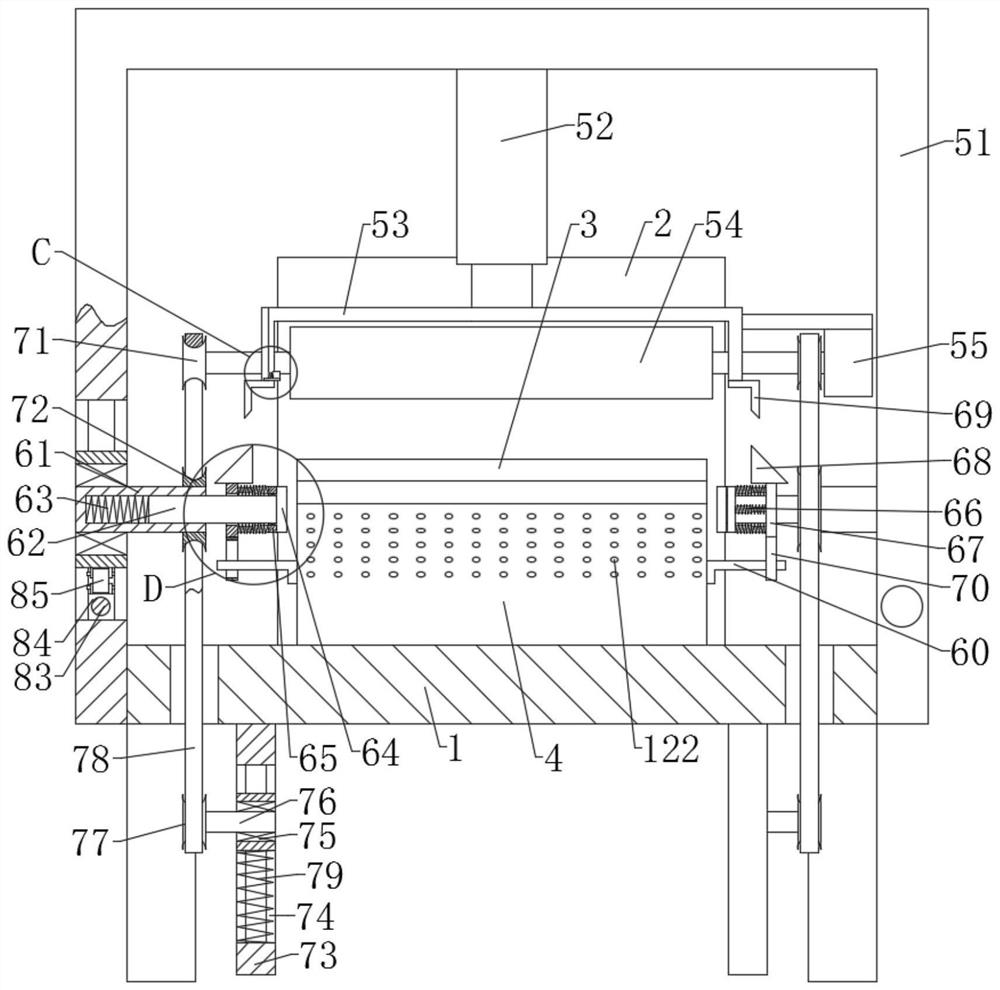

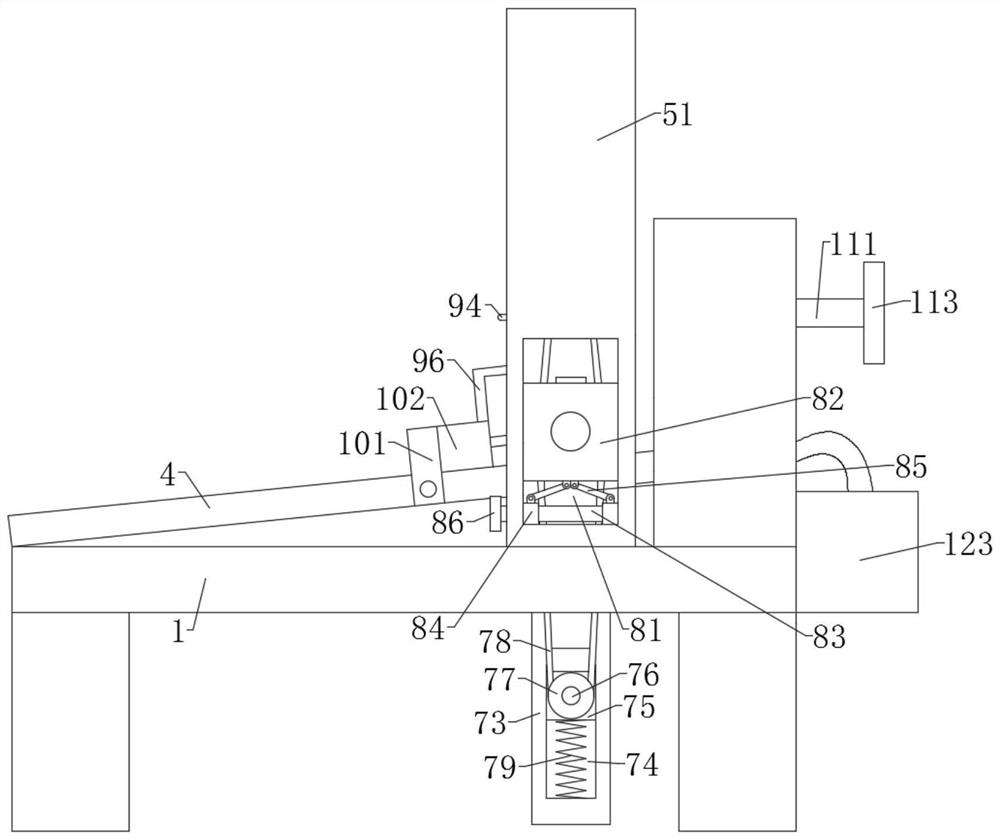

[0044] combine Figure 1-8 , the present invention provides a technical solution, a motor rotor production and processing equipment, including a base 1, the base 1 is fixedly connected with a discharge box 2, the left side wall of the discharge box 2 is provided with a discharge port 3; the top of the base 1 is provided with The inclined blanking plate 4, the right end of the blanking plate 4 passes through the discharge port 3 and is fixedly connected with the inner wall of the discharge box 2; the top of the base 1 and the left side of the discharge box 2 are provided with a processing component 5, and the processing component 5 is set There are a clamping component 6, a driving component 7, a lifting component 8, and a linkage component 9. The clamping component 6 cooperates with the driving component 7 and the lifting component 8; the top of the base 1 is provided with a baffle component 10, the baffle component 10 and the linkage component 9 Cooperate.

[0045] Wherein, ...

Embodiment 2

[0056] combine figure 1 In order to prevent the rotor from being violently hit or knocked during the falling process in the discharge box 2, a motor rotor production and processing equipment also includes an adjustment assembly 11, the adjustment assembly 11 includes a third screw 111, and the third screw 111 is screwed on the discharge box 2. On the right side wall of the material box 2, the left end of the third screw rod 111 stretches into the inner cavity of the material box 2 and is rotatably connected with an inclined deflector 112, and the right end is fixedly connected with a handle 113.

[0057] A specific application of this embodiment is:

[0058] The rotor rolls down along the left side wall of the inclined deflector 112, which can prevent the rotor from being violently hit or knocked during the falling process. The left side wall of the deflector 112 and the inner cavity of the discharge box 2 can be adjusted by the third screw 111. The distance between the side ...

Embodiment 3

[0060] combine figure 1 , 5 , in order to keep the working environment neat and clean, and to ensure the health of the staff, a motor rotor production and processing equipment also includes a dust removal assembly 12, the dust removal assembly 12 includes a dust suction chamber 121, and the dust suction chamber 121 is located inside the blanking plate 4 And located below the processing unit 5 , the top of the dust suction cavity 121 is provided with a number of suction holes 122 ;

[0061] A specific application of this embodiment is:

[0062] When the grinding roller 54 grinds the rotor, the dust suction end of the vacuum cleaner 123 sucks the dust or debris generated by the grinding through the dust suction chamber 121 and the dust suction hole 122, which ensures the cleanliness and cleanliness of the working environment and the safety of the staff. Healthy body.

[0063] The electrical components used in this patent are all commercially available, and their specific stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com