Paper compounding device for valve bag production and use method of paper compounding device

A composite device and valve pocket technology, applied in the directions of lamination devices, chemical instruments and methods, layered products, etc., can solve the composite position deviation of kraft paper and woven cloth, reduce the production quality of valve pocket substrates, and inconvenience kraft paper and woven fabrics. Cloth automatic correction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

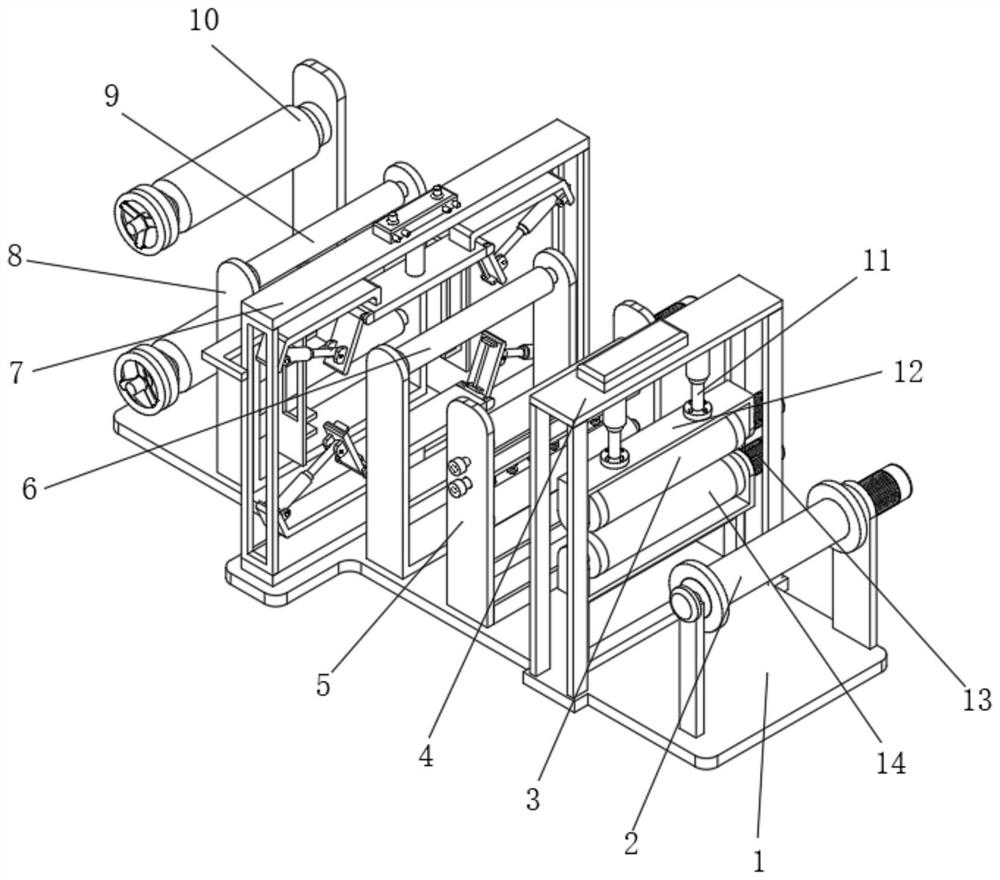

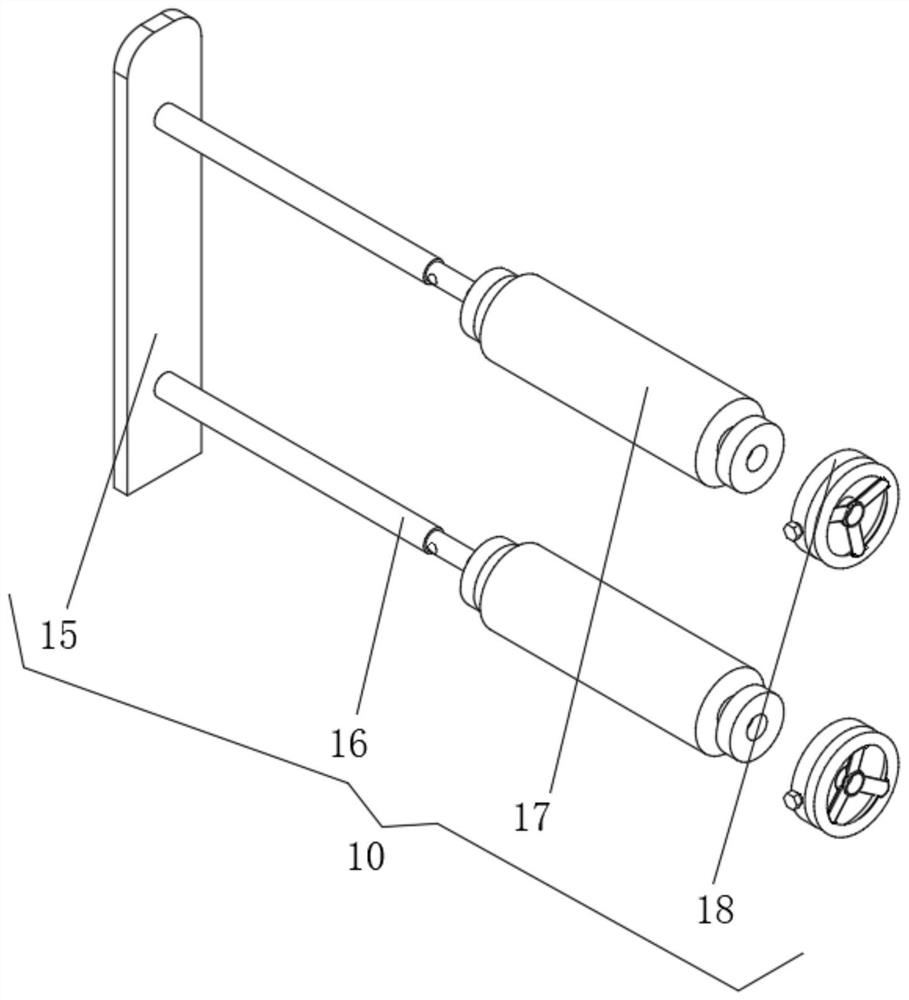

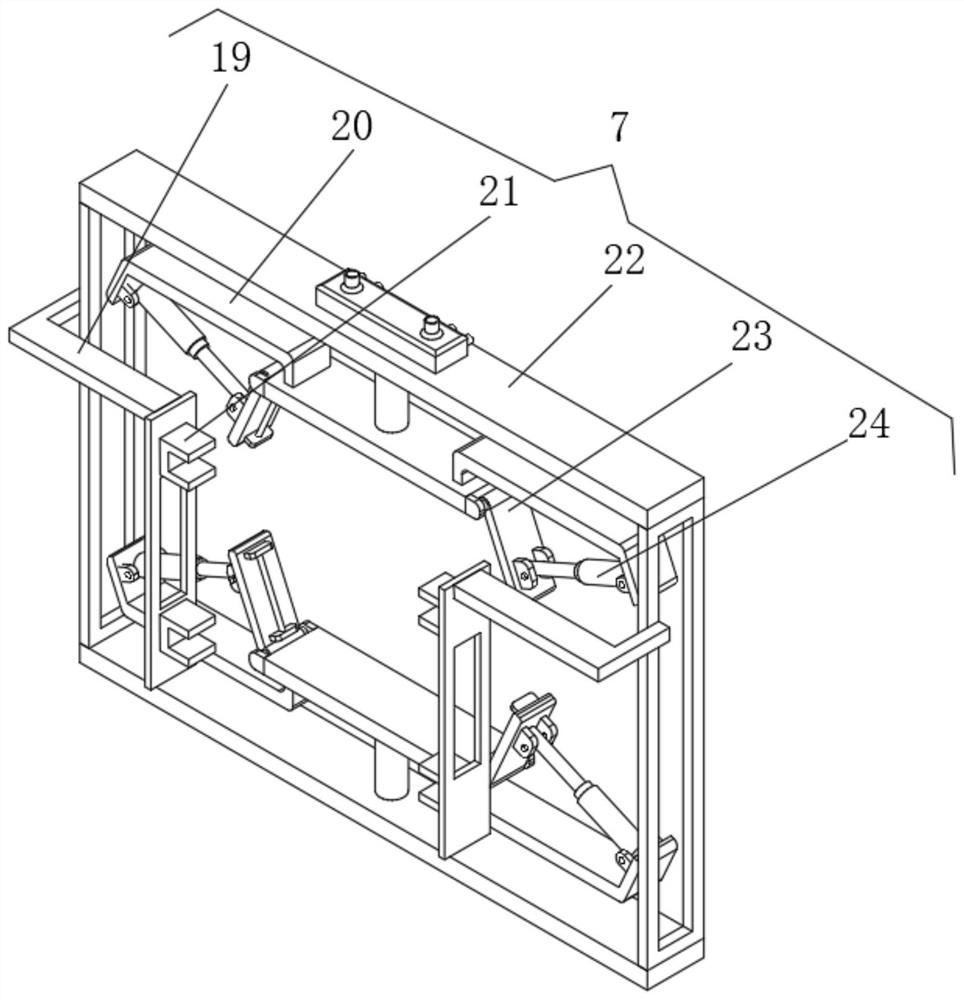

[0030] see Figure 1-Figure 6, the paper composite device for valve bag production and its use method, including a base 1, the top of the base 1 is fixedly connected with a winding mechanism 2, a frame body 4, a glue coating mechanism 5, a deviation correction mechanism 7 and a feeding mechanism 10, and the base 1 The top of the fixed frame is welded with a fixed frame 8, and the inner wall of the fixed frame 8 is respectively movably connected with the second supporting roller 6 and the first supporting roller 9 through bearings, and is used through the cooperation of the fixed frame 8, the first supporting roller 9 and the second supporting roller 6 , it can be convenient to support and limit the kraft paper and woven cloth in the conveying process, the feeding mechanism 10 includes a feeding plate 15, the front side of the feeding plate 15 is welded with a feeding rod 16, and the surface of the feeding rod 16 is movable There is a material cylinder 17, the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com