Segmented bent and attached conductive insulation protection sheet

An insulating protection, segmented technology, used in film/sheet release liners, film/sheet adhesives, adhesives, etc., can solve problems such as the inability to meet the diverse needs of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

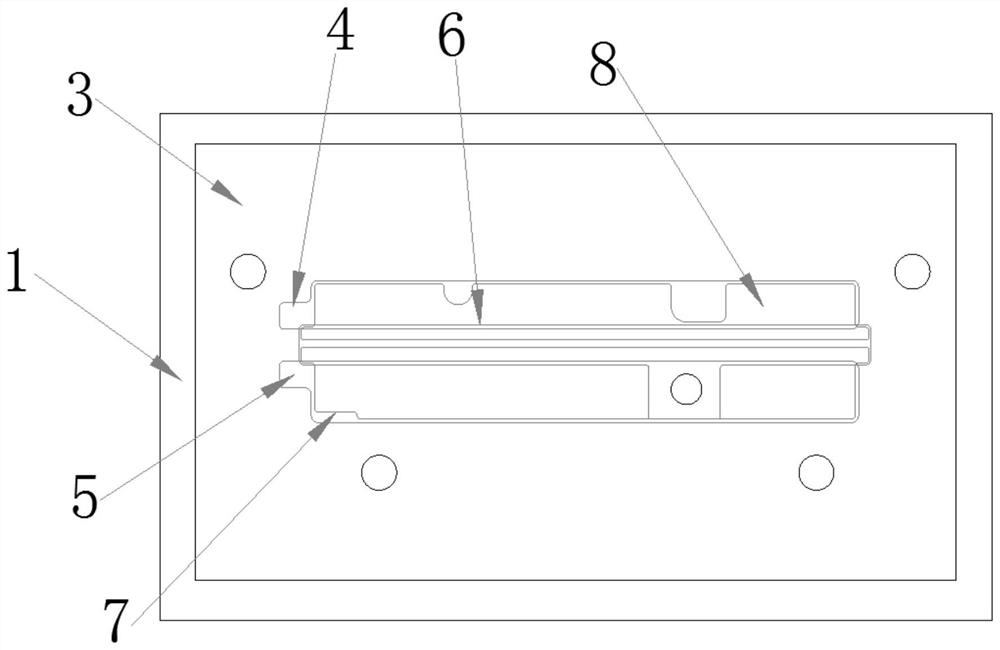

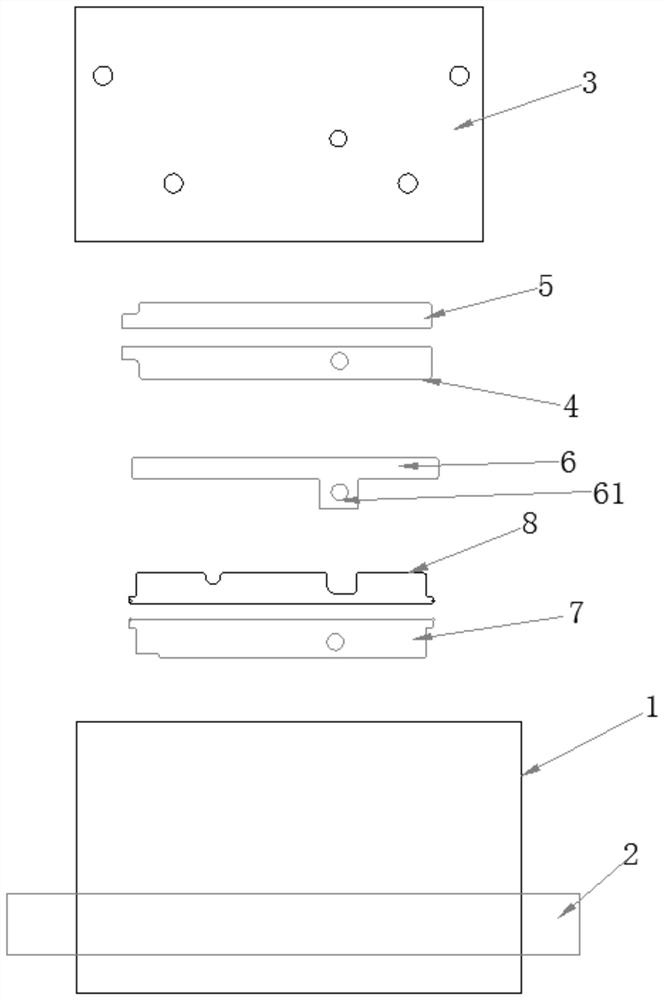

[0035] like Figure 1-2 As shown in the figure, a segmented bending and attaching conductive insulating protective sheet includes a grid release film 1, one side of the grid release film 1 is provided with MYLAR tape Ⅰ2 along its length direction, and a silicone protective film 3 covers it. On the grid release film 1 and MYLAR tape I2, a part of the silicone protective film 3 is directly bonded to the MYLAR tape I2, and the rest of the silicone protective film 3 is directly bonded to the grid release film 1 with a Conductive and insulating composite film, the size of the conductive and insulating composite film is smaller than the size of the silica gel protective film 3 bonded on the grid release film 1 . A number of conductive and insulating composite films can be bonded on the grid release film 1 through MYLAR tape I2.

[0036] The conductive and insulating composite film includes a front release film 4 and a rear release film 5, MYLAR tape II 6, and a conductive double-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com