RH (Ruhrstahl Heraeus) refining process for inhibiting 20CrMnTi steel from generating large-size TiN-containing composite inclusions

A composite inclusion, large-scale technology, applied in the field of steel smelting, can solve problems such as insolvency, achieve fine distribution, reduce heterogeneous nucleation rate, and inhibit generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example of the present invention is a typical test result in industrial production, wherein the RH refining process is:

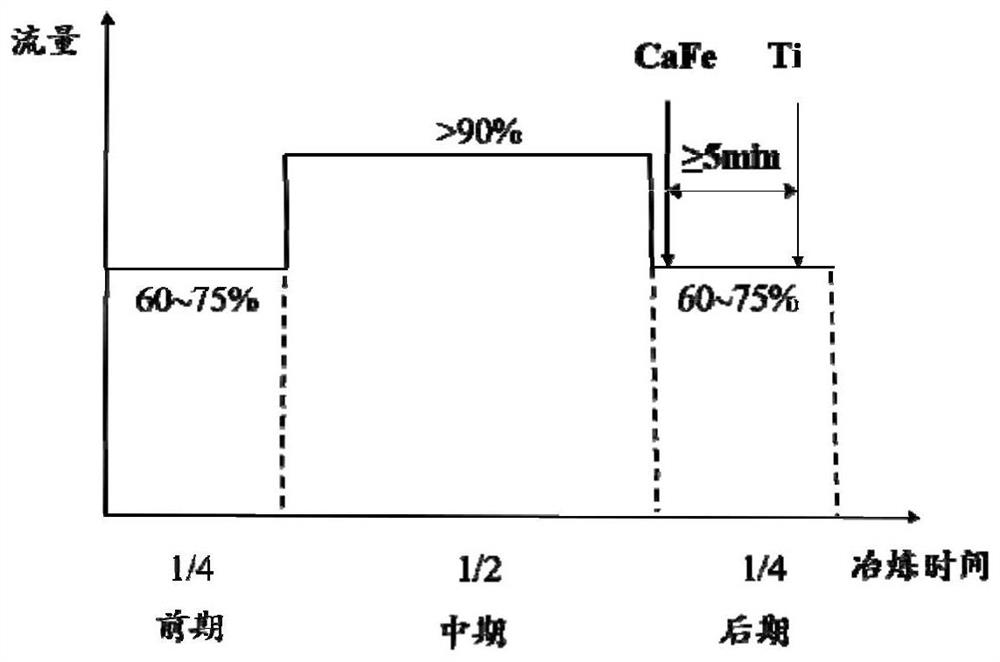

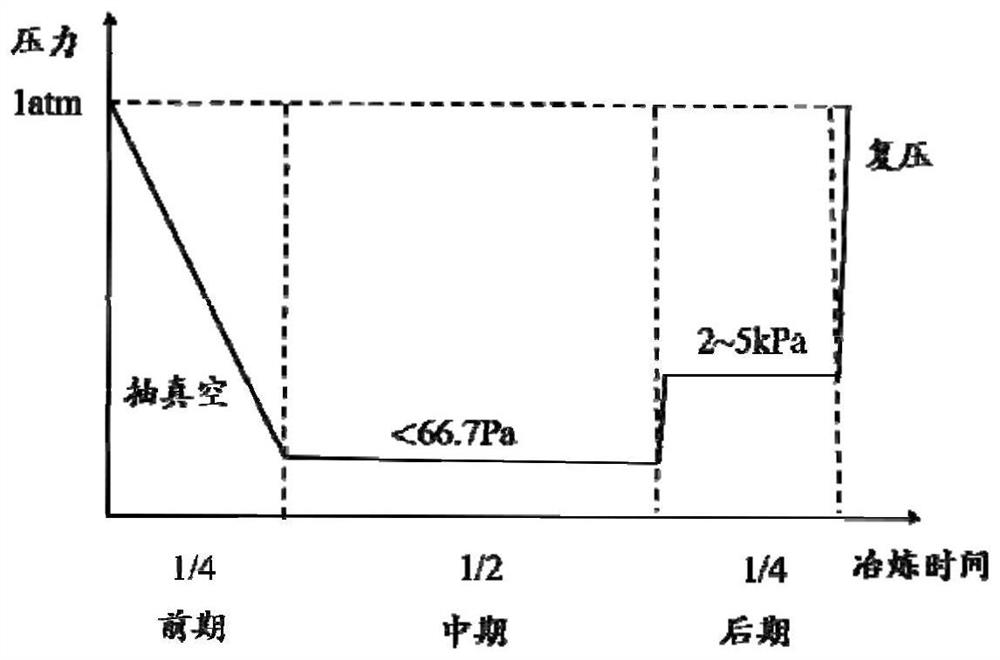

[0060] The RH refining treatment time is 40 minutes, and the refining process follows the three-stage system shown in Figure 1. The RH pre-, mid-, and post-treatment times are 10 min, 20 min, and 10 min, respectively. At the beginning of RH refining, ω[Al] in molten steel t The content is 0.045%, the pressure of the vacuum chamber in the early stage of RH is gradually reduced, the liquid level of the vacuum chamber is steadily increased, and the flow rate of argon is maintained at 14NL / min / ton of steel; min / ton of steel; the pressure of the vacuum chamber in the later stage of RH refining is kept at 3kPa, and the flow rate of argon gas is kept at 14NL / min / ton of steel. CaFe alloy with a Ca content of 10-15% is fed first for calcium treatment, and the target ω[Ca] is 0.0008%, titanium alloy is added after adding calcium and iron for 5 minutes, the ta...

Embodiment 2

[0067] Example of the present invention is a typical test result in industrial production, wherein the RH refining process is:

[0068] The RH refining treatment time is 44 minutes, and the refining process follows the three-stage system shown in Figure 1. The RH pre-, mid-, and post-treatment times are 11 min, 22 min, and 11 min, respectively. At the beginning of RH refining, ω[Al] in molten steel t The content is 0.048%, the pressure of the vacuum chamber in the early stage of RH is gradually reduced, the liquid level of the vacuum chamber is steadily increased, and the flow rate of argon is maintained at 15NL / min / ton of steel; min / ton of steel; the pressure of the vacuum chamber in the later stage of RH refining is kept at 2.5kPa, the flow rate of argon gas is kept at 15NL / min / ton of steel, and CaFe alloy with a Ca content of 10-15% is fed first for calcium treatment. The target ω[Ca] 0.0007%, calcium and iron are added 6 minutes before adding titanium alloy, the target ω[...

Embodiment 3

[0074] Example of the present invention is a typical test result in industrial production, wherein the RH refining process is:

[0075] The RH refining treatment time is 48 minutes, and the refining process follows the three-stage system shown in Figure 1. The RH pre-, mid- and post-treatment times are 12 minutes, 24 minutes and 12 minutes respectively. At the beginning of RH refining, ω[Al] in molten steel t The content is 0.042%, the pressure of the vacuum chamber in the early stage of RH is gradually reduced, the liquid level of the vacuum chamber is steadily increased, and the flow rate of argon is maintained at 16NL / min / ton of steel; min / ton of steel; the pressure of the vacuum chamber in the later stage of RH refining is kept at 4kPa, the flow rate of argon gas is kept at 16NL / min / ton of steel, and the CaFe alloy with a Ca content of 10-15% is fed first for calcium treatment, and the target ω[Ca] is 0.0006%, add calcium and iron 7 minutes before adding titanium alloy, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com