Thermal storage ceramic material and preparation method thereof

A technology of ceramic materials and ceramic fillers, applied in the field of ceramic materials, can solve problems such as equipment failure, reduced residence time, and increased bed resistance drop, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

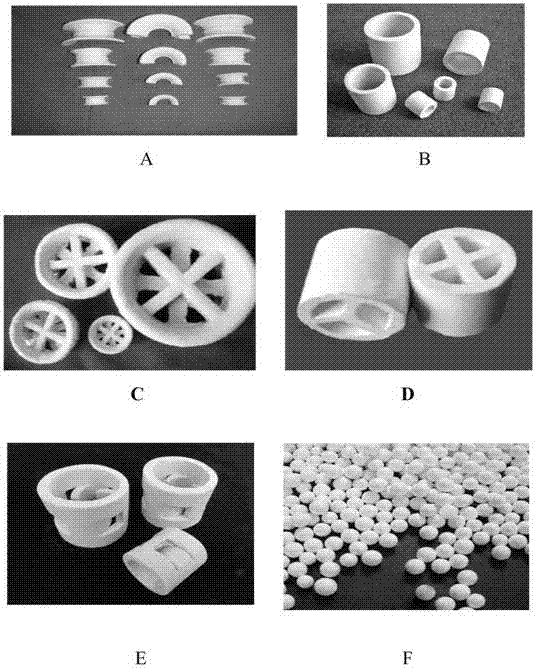

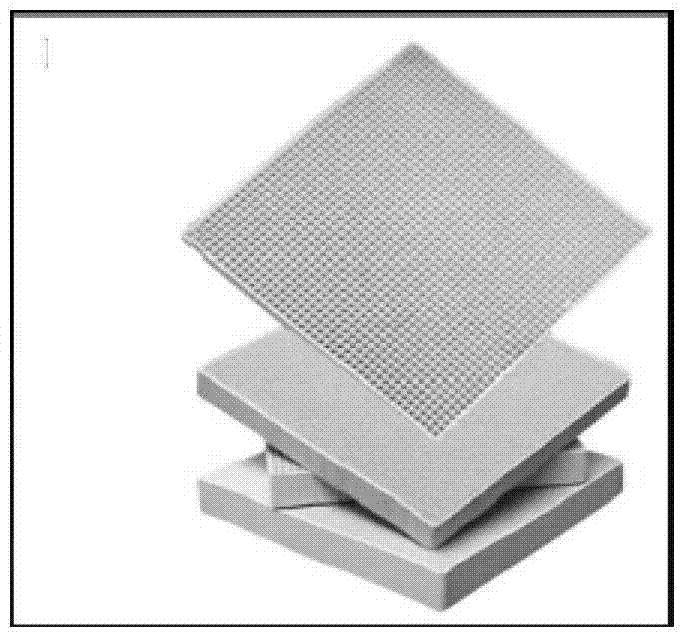

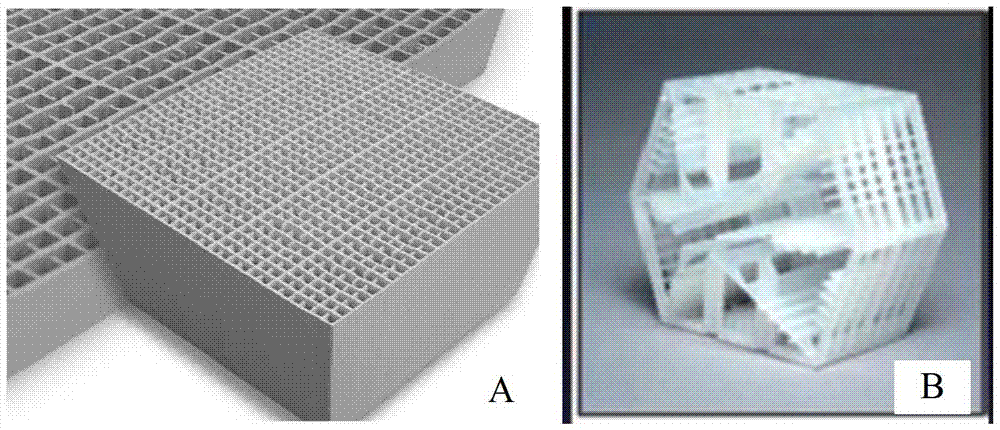

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0039] Preparation Example 1 Preparation of thermal storage ceramic materials

[0040] Step a: 6700g cordierite, 2190g Al 2 o 3 And 1010g talcum mixes, pulverizes, crosses 300 mesh sieves, obtains compound;

[0041] Step b: using a wet slurry iron removal process to remove iron in the mixture;

[0042] Step c: add 78g rare earth oxides (including La 2 o 3 、Eu 2 o 3 and Tb 2 o 3 ), the mixture is subjected to vacuum mud refining at a vacuum degree greater than 720mmHg, stale, and the stale time is less than or equal to 72 hours, and then extruded by plastic extrusion molding;

[0043] Step d: drying the mixture obtained in step c at less than 45°C for 20-60 minutes, and then sintering at 950-1000°C for 32-35 hours to obtain a heat storage ceramic material.

[0044] The component content of the thermal storage ceramic material obtained by the above method is as follows:

[0045] al 2 o 3 42.0%, SiO 2 46.7%, MgO 5.2%, rare earth oxide (La 2 o 3 +Eu 2 o 3 +Tb...

preparation Embodiment 2

[0046] Preparation Example 2 Preparation of thermal storage ceramic materials

[0047] Step a: 6810g cordierite, 2380g Al 2 o 3 And 810g talcum mixes, pulverizes, crosses 300 mesh sieves, obtains compound;

[0048] Step b: using a wet slurry iron removal process to remove iron in the mixture;

[0049] Step c: add 145g rare earth oxides (comprising La 2 o 3 、Eu 2 o 3 and Tb 2 o 3 ), the mixture is subjected to vacuum mud refining at a vacuum degree greater than 720mmHg, stale, and the stale time is less than or equal to 72 hours, and then extruded by plastic extrusion molding;

[0050] Step d: drying the mixture obtained in step c at less than 45°C for 60-100 minutes, and then sintering at 1000-1100°C for 30-33 hours to obtain a heat storage ceramic material.

[0051] The component content of the thermal storage ceramic material obtained by the above method is as follows:

[0052] al 2 o 3 47.0%, SiO 2 43.5%, MgO 3.8%, rare earth oxide (La 2 o 3 +Eu 2 o 3 ...

preparation Embodiment 3

[0053] Preparation Example 3 Preparation of thermal storage ceramic materials

[0054] Step a: 7210g cordierite, 2210g Al 2 o 3 And 970g talcum mixes, pulverizes, crosses 300 mesh sieves, obtains compound;

[0055] Step b: using a wet slurry iron removal process to remove iron in the mixture;

[0056] Step c: add 214g rare earth oxides (comprising La 2 o 3 、Eu 2 o 3 and Tb 2 o 3 ), the mixture is subjected to vacuum mud refining at a vacuum degree greater than 720mmHg, stale, and the stale time is less than or equal to 72 hours, and then extruded by plastic extrusion molding;

[0057] Step d: drying the mixture obtained in step c at less than 45°C for 80-120 minutes, and then sintering at 1100-1200°C for 30-35 hours to obtain a heat storage ceramic material.

[0058] The component content of the thermal storage ceramic material obtained by the above method is as follows:

[0059] al 2 o 3 47.3%, SiO 2 40.8%, MgO 5.2%, rare earth oxide (La 2 o 3 +Eu 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com