Hot stamping molded steel 30MnB5 and production method thereof

A production method and technology of 30mnb5, applied in the field of iron and steel smelting, can solve the problems of difficulty in meeting the strength requirements of structural parts, low product strength, etc., and achieve the effects of good performance uniformity, reduced flat roll degree, and good hardenability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

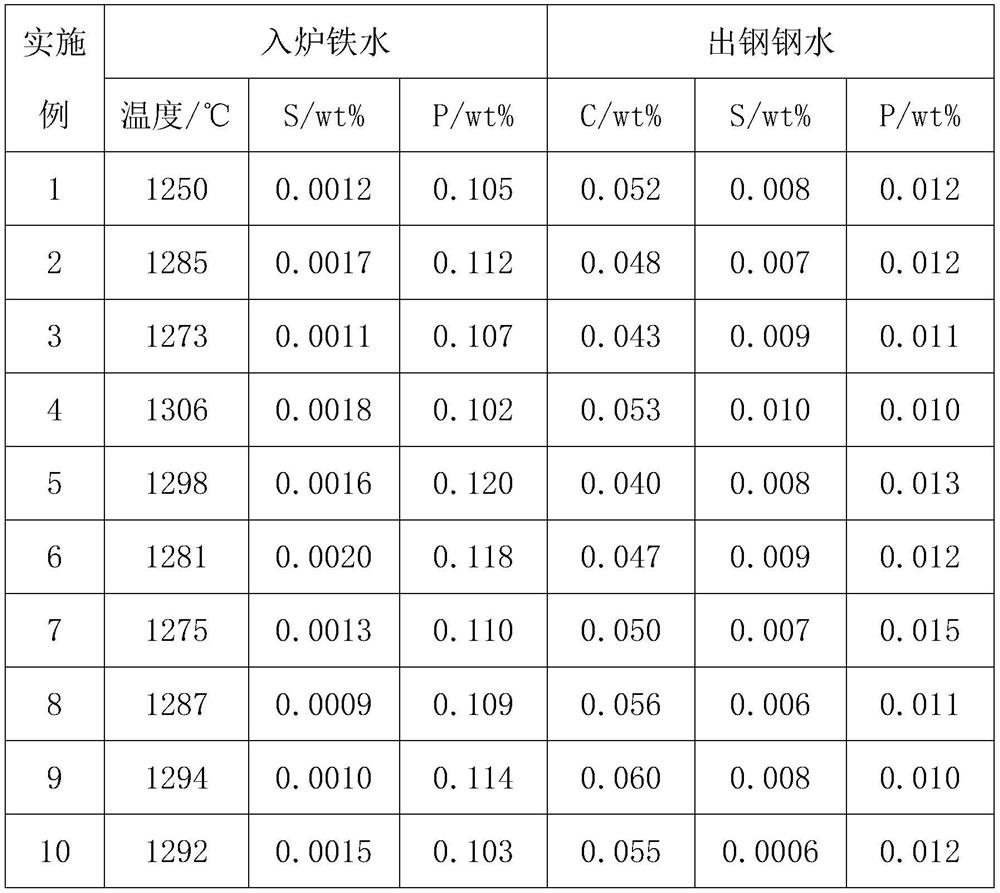

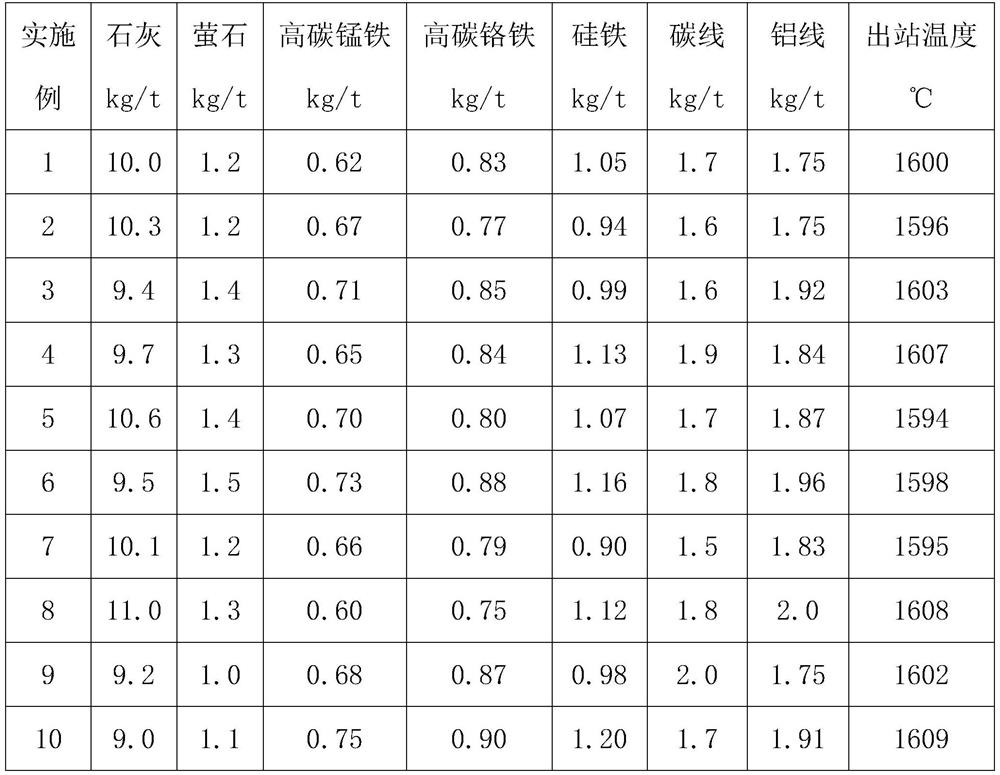

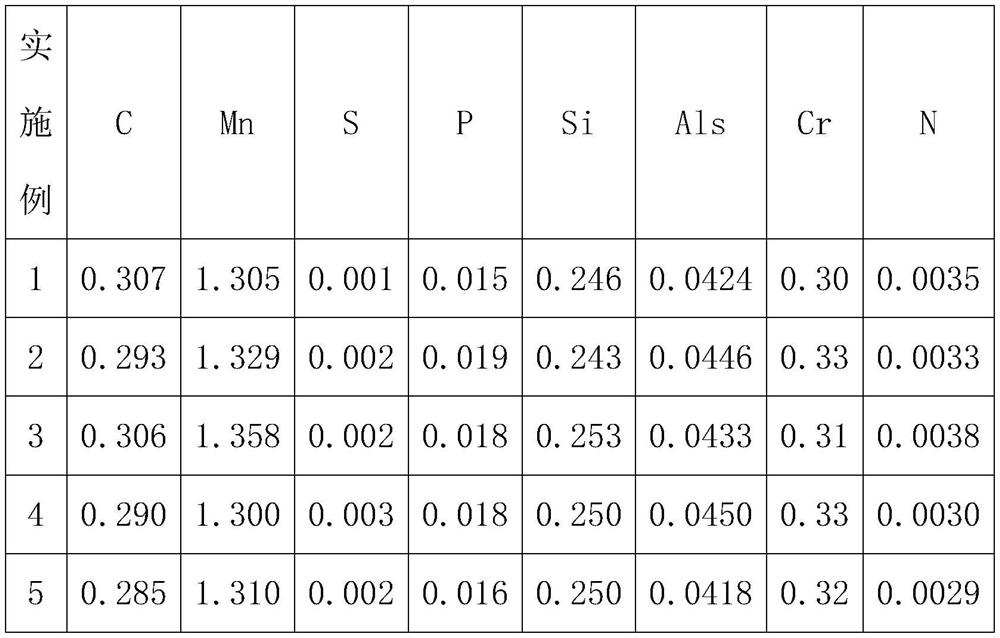

[0017] Embodiment 1-10: The production method of the hot stamping steel 30MnB5 includes hot metal desulfurization, converter smelting, LF refining, RH refining, slab continuous casting, rolling and coiling; each process is as follows.

[0018] (1) Hot metal desulfurization process: After the hot metal ladle KR stirs and desulfurizes, use a slag scraper to remove the slag, and the surface layer of the molten iron is free of slag, ensuring that the S of the molten iron entering the converter is ≤ 0.002wt%.

[0019] (2) Converter smelting process: molten iron temperature ≥ 1250°C, S ≤ 0.002%, P ≤ 0.120%; blowing process takes decarburization and dephosphorization as the main goal, and requires the whole process of slag removal; final slag basicity R is 3.3 ~3.7, composition requirements of molten steel for tapping (mass percentage): C 0.04%~0.06%, S≤0.010%, P≤0.015%, preferably S 0.006%~0.010%, P0.010%~0.013%; end point temperature : 1660~1690℃; adopt the combination of slag stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com